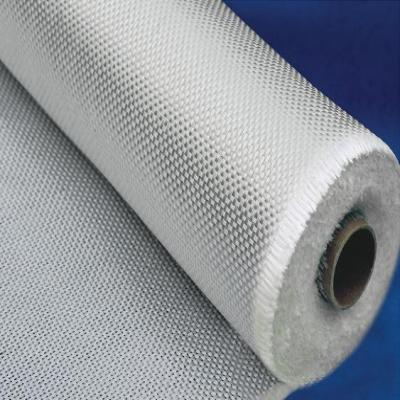

Fiberglass Fabrics - e-glass fiber woven fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 400ton kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

E-glss fiber woven roving is bidirectional fabric made by interweaving direct roving.

Woven Roving are compatible with many resin systems such as polyester, vinyl ester, epoxy and phenolic resins. Woven Roving are high-performance reinforcement widely used in hand lay-up and robot processes for the production of boats, vessels, plane and automotive parts, Pipe, furniture and sports facilities.

2.Characteristics

Top quality woven rovng fabric, E or C glass product

Woven roving fabric is bidirectional fabric made by interweaving direct roving. E-Glass Woven Roving is compatible with many resin systems such as polyester, vinyl ester, epoxy and phenolic resins. E-glass Woven Roving is a high-performance reinforcement widely used in hand lay up and robot processes for the production of boats, vessels, plane and automotive parts, furniture and sports facilities.

Product Features:

1. Warp and weft roving aligned in a parallel and flat manner, resulting in uniform tension.

2. Densely aligned fibers, resulting in high dimensional stability and making handing easy.

3. Good mold ability, fast and complete wet in resins, resulting in high productivity.

4. Good transparency and high strength of composite products.

3.Product Specifications

Items: | Warp Tex | Weft Tex | Warp Density | Woft Density | Weight | Combustible |

Ends/cm | Ends/cm | g/m2 | Content(%) | |||

WRE260 | 600 | 600 | 2.2 | 2.2 | 251-277 | 0.4-0.8 |

WRE270 | 300 | 300 | 4.6 | 4.1 | 248-274 | 0.4-0.8 |

WRE300 | 600 | 600 | 3.2 | 1.8 | 296-328 | 0.4-0.8 |

WRE360 | 600 | 900 | 3.2 | 1.8 | 336-372 | 0.4-0.8 |

WRE400A | 600 | 600 | 3.2 | 3.8 | 400-440 | 0.4-0.8 |

WRE400B | 600 | 900 | 3.2 | 2.3 | 380-420 | 0.4-0.8 |

WRE500A | 1200 | 1200 | 2.2 | 2.0 | 475-525 | 0.4-0.8 |

WRE500B | 1200 | 1750 | 2.0 | 1.6 | 495-545 | 0.4-0.8 |

WRE500T | 1200 | 1200 | 2.2 | 2.2 | 500-554 | 0.4-0.8 |

WRE550 | 1530 | 1200 | 2.0 | 2.0 | 520-570 | 0.4-0.8 |

WRE580 | 1200 | 1200 | 2.6 | 2.2 | 550-610 | 0.4-0.8 |

WRE600B | 2200 | 1200 | 2.0 | 1.6 | 600-664 | 0.4-0.8 |

WRE600C | 1290 | 1290 | 2.8 | 2.0 | 588-650 | 0.4-0.8 |

WRE600D | 1530 | 1530 | 2.0 | 2.0 | 580-642 | 0.4-0.8 |

WRE800A | 1200*2 | 1200*2 | 2.0 | 1.5 | 800-880 | 0.4-0.8 |

WRE800B | 2400 | 2400 | 2.0 | 1.6 | 820-908 | 0.4-0.8 |

WRE800C | 1750 | 1750 | 2.8 | 2.0 | 800-880 | 0.4-0.8 |

WRE800D | 1200*2 | 1530*2 | 2.0 | 1.2 | 806-890 | 0.4-0.8 |

WRE800T | 2400 | 1750 | 2.0 | 2.0 | 790-870 | 0.4-0.8 |

WRE1200A | 4000*2 | 4400 | 0.8 | 1.4 | 1190-1320 | 0.4-0.8 |

WRE1200B | 2400*2 | 2400*2 | 1.4 | 1.2 | 1190-1310 | 0.4-0.8 |

4.FAQ

Packaging & Delivery

Packaging Details: | Poly bag, then loading into carton box |

Delivery Detail: | 20 days after confirm order |

- Q: How does fiberglass fabric perform in cryogenic applications?

- Fiberglass fabric performs exceptionally well in cryogenic applications due to its unique properties. Cryogenic temperatures can significantly impact the performance of materials, but fiberglass fabric exhibits excellent thermal insulation and low thermal conductivity, making it ideal for use in cryogenic environments. One of the key advantages of fiberglass fabric in cryogenic applications is its ability to withstand extremely low temperatures without losing its structural integrity. It has a high melting point and can resist thermal stress, which ensures its durability and reliability even in harsh conditions. This makes fiberglass fabric suitable for use in cryogenic storage tanks, pipelines, and other equipment that handle liquefied gases such as nitrogen, oxygen, and LNG (Liquefied Natural Gas). Additionally, fiberglass fabric has low thermal expansion, meaning it does not contract or expand significantly when exposed to extreme temperature changes. This property is crucial in cryogenic applications as it helps prevent leaks or cracks that could compromise the integrity of the system. Furthermore, fiberglass fabric is non-corrosive and resistant to chemicals, making it suitable for use in cryogenic environments where exposure to potentially corrosive substances is common. It does not react with most cryogenic fluids, ensuring that the fabric remains intact and does not degrade over time. Another important factor is the excellent electrical insulation properties of fiberglass fabric. Cryogenic applications often involve the handling of electrical components, and using fiberglass fabric as an insulating material helps prevent electrical conductivity issues that could arise due to temperature fluctuations. Overall, fiberglass fabric performs exceptionally well in cryogenic applications due to its thermal insulation, low thermal conductivity, high melting point, low thermal expansion, chemical resistance, and electrical insulation properties. These characteristics make it a reliable and durable material for use in various cryogenic systems and equipment.

- Q: Can fiberglass fabrics be used for reinforcement in furniture or fixtures?

- Yes, fiberglass fabrics can be used for reinforcement in furniture or fixtures. The strength and durability of fiberglass make it an excellent choice for adding structural support to various types of furniture and fixtures, ensuring their longevity and stability.

- Q: How does fiberglass fabric perform in high-temperature environments?

- Fiberglass fabric is known for its excellent performance in high-temperature environments. It is a type of fabric made from glass fibers that are woven together to create a strong and durable material. One of the main advantages of fiberglass fabric in high-temperature environments is its ability to withstand extreme heat. It has a high melting point, typically around 1470°C (2678°F), which makes it suitable for applications where temperatures can reach very high levels. In addition to its high melting point, fiberglass fabric also exhibits excellent thermal insulation properties. It has a low thermal conductivity, meaning it resists the transfer of heat. This makes it an ideal choice for applications where heat needs to be contained or insulated, such as in the construction of fire-resistant barriers or thermal insulation blankets. Furthermore, fiberglass fabric is highly resistant to fire and does not burn easily. It is non-combustible and does not contribute to the spread of flames, making it a safe choice for high-temperature environments where fire hazards are a concern. Another notable characteristic of fiberglass fabric is its dimensional stability under high temperatures. It maintains its shape and integrity even when exposed to extreme heat, which is crucial for applications where precise dimensions are required. Moreover, fiberglass fabric is resistant to many chemicals and corrosive substances, which further enhances its performance in high-temperature environments. It can withstand exposure to acids, alkalis, and solvents, ensuring its durability and longevity even in harsh conditions. Overall, fiberglass fabric is a reliable and versatile material that performs exceptionally well in high-temperature environments. Its ability to withstand extreme heat, provide thermal insulation, resist fire, and maintain dimensional stability makes it a preferred choice for a wide range of applications in industries such as aerospace, automotive, construction, and manufacturing.

- Q: How does fiberglass fabric perform in high-humidity environments?

- Fiberglass fabric performs exceptionally well in high-humidity environments. Due to its non-absorbent nature, it does not retain moisture and remains unaffected by the presence of water vapor in the air. This means that even in high-humidity conditions, fiberglass fabric maintains its structural integrity, strength, and dimensional stability. It does not warp, shrink, or become brittle like some other materials in humid conditions. Additionally, the non-porous nature of fiberglass fabric prevents the growth of mold, mildew, and other fungi that thrive in moist environments. This makes fiberglass fabric an excellent choice for applications such as boat building, outdoor furniture, and construction projects in high-humidity areas. Overall, fiberglass fabric's resistance to moisture and its ability to withstand high-humidity environments make it a reliable and durable material in such conditions.

- Q: What is the width range of fiberglass fabric?

- The width of fiberglass fabric can differ based on the manufacturer and intended purpose. Typically, fiberglass fabric can be found in widths ranging from 30 to 60 inches. Certain specialized fabrics may be obtainable in wider widths, even surpassing 100 inches. To determine the available width choices for a specific fiberglass fabric, it is crucial to consult the designated manufacturer or supplier.

- Q: Is fiberglass fabric resistant to rodents?

- Generally speaking, fiberglass fabric exhibits resistance to rodents. Rodents are not inclined to find the material appetizing, resulting in a decreased likelihood of them chewing or gnawing on it in comparison to materials like wood or plastic. This resistance explains why fiberglass fabric is a favored option for insulation in areas like attics and crawl spaces, where rodents are often present. Nevertheless, it is crucial to acknowledge that fiberglass fabric is not entirely impervious to rodents. In exceptional circumstances, rodents may still endeavor to chew or tunnel through the fabric if they possess a strong motivation or if the fabric sustains any form of damage or compromise.

- Q: How does fiberglass fabric perform in moisture resistance?

- Fiberglass fabric performs exceptionally well in moisture resistance. Due to its composition and structure, it is highly resistant to water absorption, making it an ideal choice for applications that require protection against moisture and humidity.

- Q: How to distinguish carbon fishing rod?

- Glass steel pole rough texture, mesh patterns, can be seen across the warp, weft. Carbon rod fine texture, no pattern wall, a black color, even some reticular pattern, and carbon fiber cloth, the fine, silvery white, glass and steel rods significantly different warp and weft weaving. Carbon pole strength, good conductivity, wear resistance, high temperature resistance, corrosion resistance characteristics.

- Q: How does fiberglass fabric perform in chemical exposure?

- The performance of fiberglass fabric in chemical exposure is exceptional. It is widely used in various industries where exposure to corrosive substances is expected, thanks to its inherent resistance to a wide range of chemicals. The fabric is composed of woven glass fibers, which create a strong barrier against chemical attack and degradation. Fiberglass fabric can withstand exposure to acids, alkalis, solvents, and other corrosive chemicals without significant damage or deterioration in many cases. This resistance to chemical attack makes it an excellent choice for chemical storage tanks, pipes, ducts, and equipment linings. Furthermore, the fabric's non-reactive nature prevents contamination or leaching of chemicals into the surrounding environment, making it a safe and reliable option for handling hazardous substances. Additionally, its thermal insulation properties enhance its performance in chemical exposure by providing protection against extreme temperatures that may accompany certain chemical processes. However, it is important to consider that the specific performance of fiberglass fabric in chemical exposure may vary depending on factors such as the type and concentration of the chemical, as well as the duration and temperature of exposure. Therefore, it is always advisable to consult manufacturers or industry experts to ensure the suitability of fiberglass fabric for a specific application and to determine any necessary precautions or compatibility considerations.

- Q: Is fiberglass fabric breathable?

- Lacking breathability, fiberglass fabric is composed of woven glass fibers that form a compact and impenetrable structure, impeding the smooth flow of air. Such a characteristic renders fiberglass fabric ideal for insulation, fireproofing, and safeguarding against chemicals and abrasion. Nevertheless, it has the potential to confine heat and moisture, resulting in potential discomfort in specific circumstances.

Send your message to us

Fiberglass Fabrics - e-glass fiber woven fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 400ton kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords