Milled Glass Fiber

Milled Glass Fiber Related Searches

Chopped Glass Fiber Glass Fiber Filler Glass Fiber Mat Woven Fibreglass Fiber Glass Mat Glass Fibre Surface Chopped Fiberglass Glass Grinding Wheel Glass Grinding Equipment Fiberglass Filament Winding Machine High Pressure Fiberglass Pipe Car Fiberglass Textile Fiber Fibreglass Pipes Fiberglass Fabric Fibreglass Fabric Fiberglass Woven Resin Fiberglass Fiberglass Woven Fabric S Glass Fiberglass Fiberglass Thermal Insulation Silver Fiber Fabric Black Glass Fiber Tissue Fiberglass Roving Fiberglass Yarn Glass Reinforced Epoxy Fibreglass Mesh Tape Frosted Plexiglass Fibreglass Resin Fiberglass ResinMilled Glass Fiber Supplier & Manufacturer from China

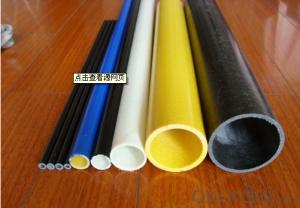

Milled Glass Fiber, also known as glass microfiber, is a type of glass fiber product that has been finely ground to create a versatile material with unique properties. This product is widely recognized for its excellent strength, durability, and resistance to various environmental conditions, making it suitable for a range of applications. Milled Glass Fiber is commonly used in construction, automotive, aerospace, and electronics industries, among others, due to its ability to enhance the performance of composite materials and improve thermal insulation.The usage scenarios for Milled Glass Fiber are vast, as it can be incorporated into various products and systems to provide enhanced strength, reduce weight, and improve overall performance. In construction, it is often used in the production of reinforced concrete and plaster, while in the automotive industry, it is utilized in the manufacturing of lightweight and strong vehicle components. Additionally, Milled Glass Fiber plays a crucial role in aerospace applications, where it contributes to the structural integrity of aircraft and spacecraft. In the electronics sector, this product is employed in the production of high-performance printed circuit boards and other components that require excellent thermal management.

Okorder.com is a leading wholesale supplier of Milled Glass Fiber, boasting a large inventory of this high-quality product. As a reliable source for glass fiber materials, Okorder.com ensures that customers have access to a wide range of Milled Glass Fiber options to meet their specific needs and requirements. By partnering with Okorder.com, businesses can benefit from competitive prices, fast shipping, and exceptional customer service, making it a go-to destination for those seeking to incorporate Milled Glass Fiber into their products and applications.

Hot Products