Grinding Glass Beads

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Kilograms kg

- Supply Capability:

- 500 Tons per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

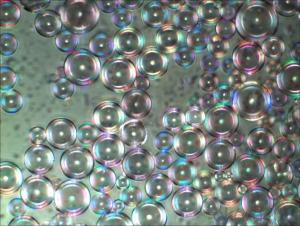

Grinding Glass Beads

strong hardness

new glasses for material

Round ratio above 85%

ISO, CE

Grinding Glass Beads

III. Hardness

HV, Loading 100g, residence time: 12s

the average of five point: 5270Mpa

standard

code(HV): ≥ 5000Mpa

IV. percentage of damage

1. test condition

(1)shot peening Target:Thickness:1.2mm (steel plate)

(2)air pressure of the nozzle:0.3Mpa

(3)the space between the nozzle and the Target: 200mm

(4) time of shot peening:5min

(5)the diameter of the glass beads: 250 microns

(6)Gross Weight of the tested glass beads: 1020g

(7) the weight of the damaged

glass beads after shot peening: 1.02g

2.percentage of damage of the test : 0.1%

V. Application

They are mainly used for the disperser, grinding media of industries, such as coloring, paint, ink, coatings, resins, chemical engineering, with the advantages of smooth surface, even size, high hardness, good chemical stability. Thanks to the characteristics of heat-resistant, wearable, compression strength, the filling-type bead could be used to improve glass fibre reinforced plastic, rubber, and so on.

- Q: The working principle of a pile driver ship

- The piling ship is equipped with a pile hammer, a pile stand, and auxiliary equipment.

- Q: Types of pile drivers

- Spiral pile driver (Spiral hammers) is a power driven drill head drill bit into the underground drilling machine drilling equipment. The spiral pile driver can be divided into two parts: the pile foundation and the drilling part.

- Q: Can a small country pile driver be able to hit a stone?

- micro special vehicles and C2, C3, C4. Which color car license did you say? What about the maximum load?Supplement:C1 seems to be the open quality (weight + weight) of 4.5 tons.

- Q: Handan steel sheet piling machine a number of how much money

- According to the quality450 pile driverHit 9m Larson steel sheet pile about 100300 pile driver

- Q: How much is the average cost of piling a metre?.Construction Engineering piling machine how much money? (can be more than 30) piling generally hit a meter, what is the cost?. How much can I pay for a metre? What's the procedure for piling operators?

- Domestic about 2000000, the best to count Germany and Italy one, at least 500 - about 6000000! About one meter.

- Q: In the construction project, the pile driver can not be reached. What should the supervisor do?

- Hold supervision meeting;Analysis reason;Take out the treatment plan.

- Q: What machinery is used for piling?

- In fact, in some places with artificial, you can go to buy a wylong machinery piling machine equipment is good, driving fast and convenient and money

- Q: What is the noise of a static pile and a diesel pile driver?

- The noise of the static pile is small, so it is suitable for the construction in the city and the construction cost is higher.The diesel pile driver has large noise and is suitable for field construction, and the construction cost is low.

- Q: How many small pile drivers are there in Hunan? It's best to have the exact location

- Hunan small piling machine manufacturers or a lot, like Hunan wylong machinery should be more excellent in mechanical industry.

- Q: Which brand is better for a small pile driver?

- Shandong Tengzhou is a small piling machine production base, basically are small and medium enterprises engaged in such equipment, as of 31, the brand is not so loud as Xugong, buy piling machine the key is to look at each manufacturer of the scale,

1. Manufacturer Overview

| Location | Liaoning, China (Mainland) |

| Year Established | 2000 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe |

| Company Certifications | ISO:9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Grinding Glass Beads

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Kilograms kg

- Supply Capability:

- 500 Tons per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords