Pile Driver (DPD Tilting Clamp Type Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Pile Driver (DPD Tilting Clamp Type Series)

-360 degrees free rotation & 90 degrees tilting rotation of jaw clamp

-Simple replacement tooth of pile clamp

SHEET PILE DRIVER (TILTING TYPE)

DPD Tilting Series

(PATENT NO.10-0851430)

- 30% better efficiency of construction working site

- 90 degrees Tilting devices

- Easy & Accurate control tilting operation system

- Tested safety through double device

- This leads to greater customer satisfaction!

- The tilting sheet pile driver can be operated alone ; No necessary assistant worker

- As it tilts up to 90 degree, the operation with sheet pile, H beam, tube, pipe, and steel can easily be controlled without the help of another worker. The cost of one worker can be saved

- Maximizes operational performance with its much more enhanced functions

- Best in 35 ton class for impulse and clamping power

- Dramatically reduces costs of transport and assistant worker

- Highly improved sheet piling operation method

- Extended service life using a special bearing designed for high frequency vibration

- Heavy duty Special elastomers (Patent) isolate vibration protecting the excavator from damage

- Making the best use of the excavator, operation in a narrow space is possible

- Easy installation using breaker hydraulic lines of the excavator and electric one control cable device

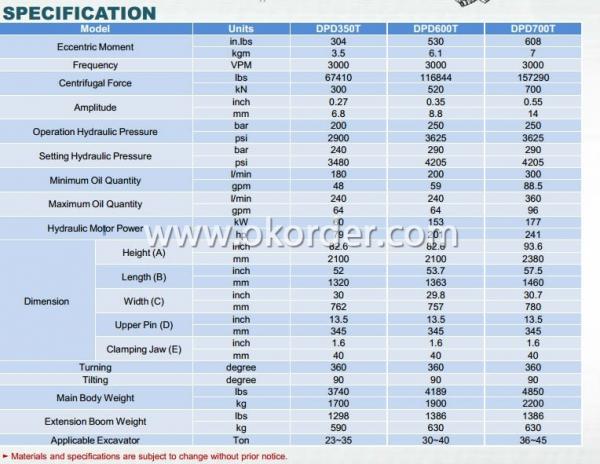

Specification of Pile Driver (DPD Tilting Clamp Type Series)

- Q: What does "driving pile" mean based on dynamic compaction?

- Based on the dynamic compaction pile is: dynamic compaction cannot meet the upper building foundation structure, also need to further strengthen the strength of the foundation piling.

- Q: Rural housing foundation, piling machine generally can play how deep?

- 3, the use of XCMG power head, multi-stage shock absorption technology to ensure that the overall construction of more stable, power head key bar used in reverse and used to extend its service life.4 、 adopting the lock rod of the XCMG machine and the automatic lowering technique of the mast. The vertical precision of the pile hole is higher, and the construction is more convenient.5, the well-known brand "Yuchai engine," every little hour consumption 40-50 yuan.6, the use of wide, tube rice suitable for medium weathering below rock layer, sediment layer, backfill soil layer and other complex landforms.

- Q: How much is the hydraulic pile driver?

- Between 16-40, 000. Different manufacturers. Different tonnage difference big ah, soft land dozen20 tons will be enoughI hope my answer is useful to you, if satisfied, please take ~!

- Q: what kind of VLV cable is needed, how to determine, after the cable from the low-voltage distribution box out, 460m arrived distribution of electricity 100It's best to explain how to calculate, how to determine the current, and the specifications of the cable, thank you very much!630 of the box changed to the distribution box for the cable, 240 of the cable is single core, or 3*240 cable. What kind of cable can be specific about it? Underground directly buried, directly to a cable model, aluminum core cable

- Current of pile driver 5*75=375KW/0.8=468.75KW/380/1.732=712AThe ampacity of the cable is 240 square meters, about 390ASo we need two 240 square parallel.

- Q: Precast pile, artificial dig hole pile, sinking pipe filling pile, spiral drilling pouring pile and powder spraying pile.

- You need to use the term piling machine and every possible operation and maintenance costs have a general understanding, if each year period divided by total amount plus maintenance costs less than the lease, you can consider buying, similar or greater, or lease more appropriate.

- Q: Under the high voltage line, within two meters on both sides, no pile driver shall be installed

- No piling machine shall be installed within 10m on both sides of high tension line. In case of special circumstances, the safety technical measures must be taken and the installation can be installed after the approval of the higher technology supervisor.

- Q: Such as the title... Phenomenon: quiet with a sound to length, rises again, continuous... Better knowledge about this point for more,...

- This is a hammer driven pile driver that uses diesel fuel to ignite, hammer upward, then drop free, and pile the pile by gravity. Generally used for concrete precast pile and steel pipe pile and so on.

- Q: Safety requirements for diesel hammer pile drivers for diesel hammer pile drivers

- 11 water cooled diesel hammers shall be maintained with sufficient cooling water for continuous work and shall not be used without water. 12 operation, diesel hammer final ten hit penetration should comply with the provisions of the use manual, when every ten hit penetration is less than 20mm, should stop hammering or replace pile hammer. 13 during the piling process, lubrication and repair shall not be performed. 14 when the hammer (pile) of pile driver is used, the minimum distance of hammer (pile) from the top of column shall be ensured. 15 after the pile is inserted, the verticality of the pile should be corrected in time. When the pile is embedded in the 3M, the pile should not be taken for walking or turning to correct it. The 16 batter pile, the vertical pile should be vertical, the pile into fixed, and then began to tilt, tilt 18.5 degrees in the post, should not raise diesel hammer. Track three fulcrum type pile frame in the backward of batter pile, should use the rear leg cylinder; track type pile frame should be increased after the support platform, and clamping rail clamp. 17 when driving, the diesel hammer shall be lowered to the lowest position, and the slope shall be in accordance with the instruction manual. Self propelled pile drivers should be manned by hand. When walking on the ramp, the center of gravity should be moved to the top of the ramp. The distance from the pipe type piling machine to the end of the roller tube shall not be less than 1m. 18 during operation, the slewing brake should be slow, and the track type and walking type pile stand shall be turned in the same direction, not more than one week.

- Q: My family from the building, a three storey, only two and half layer design now, frame structure and prefabricated panels, a total of three half empty, with the inner diameter of the air is piling machine, 30CM in the field, with an average depth of 6 meters, I asked how wide a safe? The master said, "one meter, one. I feel a little too dense."! Ask everybody specially!How many meters can I use if I choose an empty 80CM pile driver? My maximum span is 4 meters, and some are 3 meters and 2 meters. Because the master is how many piles count money, so there is little doubt!

- The spacing of the piles is usually 3-3.5 times the diameter.

- Q: How much are the pile and Larson piles of a pile driver?

- Would you like to ask the price of the material or the price of the construction?AskMaterial priceChasing the answerI mainly do Larson steel sheet pile products. Domestic 5000 or so, Japan imports 6450.

1. Manufacturer Overview

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pile Driver (DPD Tilting Clamp Type Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords