Vibro Ripper (DBL Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Sets watt

- Supply Capability:

- 1000 Sets per Month watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Vibro Ripper (DBL Series)

-Innovative, Reliable Original Vibro Ripper in The World!

-Powerful digging force by special vibration structure

VIBRO RIPPER

(DBL Series )

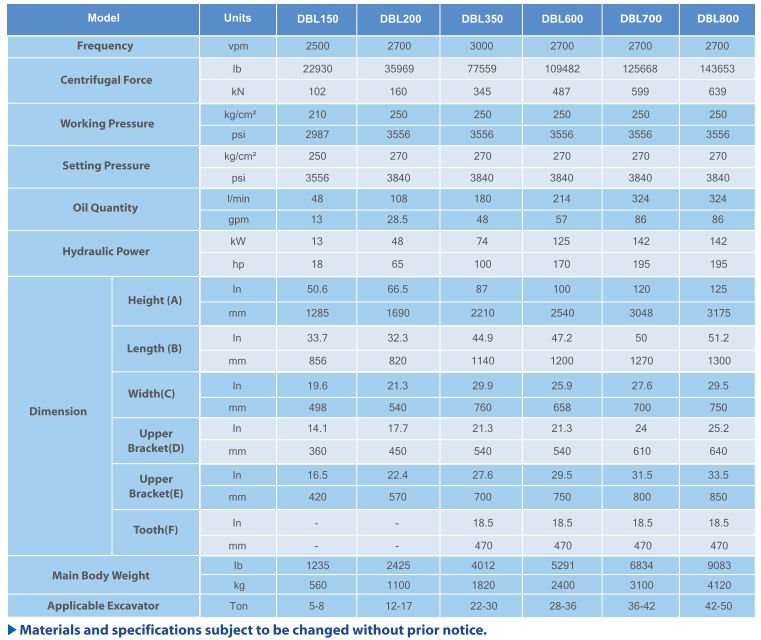

DBL150, DBL200,DBL350,DBL600,DBL700,DBL800

Patent Status

-World Patent PCT No.KR2007/004427

-U.S.A Patent No.12/673,152

-European Patent No.07 808 218 7

-Korea Patent No.10-0755017, No.10-0878296

-Innovative, Reliable Original Vibro Ripper in The World!

-Powerful digging force by special vibration structure

-Noiseless & Eco-friendly Vibrating Ripper

-No scattering of debris during digging operation

-Higher Production & efficiency

-Noiseless and eco friendly equipment (approx. 52~65dB lower than an equivalent hammer)

-Up to double and three times of productivity compared with an equivalent hydraulic hammer

-Easy installation to excavator with breaker hydraulic lines

-Utilizes 2,700rpm of high frequency vibration

-Patented heavy duty of elastomers(cushion elastomer) insolates the excavator from vibration shock

-Mounting and dismounting with 5~40 ton excavator boom at any time easily

-Innovatively designed tooth & pin have improved the durability

-Powerful breaking performance by high frequency motor

-Innovative technology, more powerful vibration and less noise level than ever

-Increased life time for the equipment by applying the oil rotation power system

-Developed with a patented high frequency vibration technology world first, which makes it in 80% of job site more productive than any rock breaker.

-Application area : it can work in tunnels, road extension section, public grievance, downtown, foundations, muddy, wet zone and under water places

Technical Specification of Vibro Ripper (DBL Series)

- Q: The difference between diesel pile driver and impact drilling machine

- A diesel pile driver: like a hammer hitting a nail, it is hit by a hammer.

- Q: What is a pile driver used for?

- As the name suggests, of course, piling is used, such as building houses, foundations, bridges, foundations and so on. For soft foundation construction site, the design of concrete prefabricated pile or steel pipe pile made of pile, use a pile driver to hit the ground until the design of the formation.

- Q: What does piling mean?

- Piling is the construction of pile foundation, that is, the prefabricated pipe pile pressed into or into the soil; also can be said that the construction of concrete pouring pile and so on. Piling is a popular term.

- Q: What are common piling steel pile equipments?

- 3, piling ship, hull steel box structure, the deck with pile frame, can be applied to meet the need of batter pile up.4, static piling machine, static piling machine is a relatively new piling equipment, with low noise, small vibration, driving speed, the construction site of the advantages of less pollution, but the cost is relatively high, the current construction is still relatively less used.

- Q: I have a pile machine construction record card, but Supervision said or not, please master pointing.

- If there is any nonconformity, the rectification shall be completed and checked by the supervision.

- Q: How much is piling foundation for pile driving machine?

- A pile driver in Hunan Huilong domestic piling machine is relatively good, driving speed is very fast, with less, the most important is the customer service service is very good,

- Q: Several common pile foundations and pile driving techniques

- Bored pile foundation construction - long spiral drilling bored pile construction, the main processes are: site preparation, the laying of protective cylinders, preparation of mud, drilling, cleaning, reinforcement cage, into the hole and pouring underwater concrete. The key is drilling, the main methods are: rotating method, impact method and punching method. The rotary drilling can be divided into positive revolving drilling, reverse circulation rotary drilling, long spiral drilling machine and so on. Bored pile foundation construction - reverse and reverse rotating drilling, positive rotation drilling: mud from the mud pump at high pressure from the mud tank into the bore of the drill pipe, the drill hole through the mouth of the injection.

- Q: How to hit a pile of photovoltaic power generation?

- Do you have anything to live with? I have a photovoltaic machine. What ground is it, earth or stone?

- Q: What's the use of a pile driver?

- It is a spiral into the hole, drilling, torsion, flexible application in different soil, different pile rod, a Hunan photovoltaic site ente spiral auger, the finished pile rod placed in a spiral drill under the hook on the second column, is a very typical case of PV column pile. With such an efficient job, wouldn't it make you realize your dream of getting your cost back in 10 days?In addition, it can be applied for diversified garden landscaping, well drilling, drilling, sampling, planting pit coal pillar foundation drilling, bridge with pit wells, drilling hole, wind generator column pole hole (hole) of the drill, expand your business to expand your money.Choose gornt heavy bosses don't have to worry about the machine idle.

- Q: Buying a pile driver doesn't know how to make a profit Has anyone done that yet?

- Because, after all, the pile driver is not only a few years, the choice of good quality in the early may not be cost-effective, but after taking into account, or suggest that you buy a little bit of the machine. After all, if the driver problem that you every two or three days, the work is not good for.

1. Manufacturer Overview

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vibro Ripper (DBL Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Sets watt

- Supply Capability:

- 1000 Sets per Month watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords