Korean Excavator Vibro Attachment

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Sets set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Korean Excavator Vibro Attachment

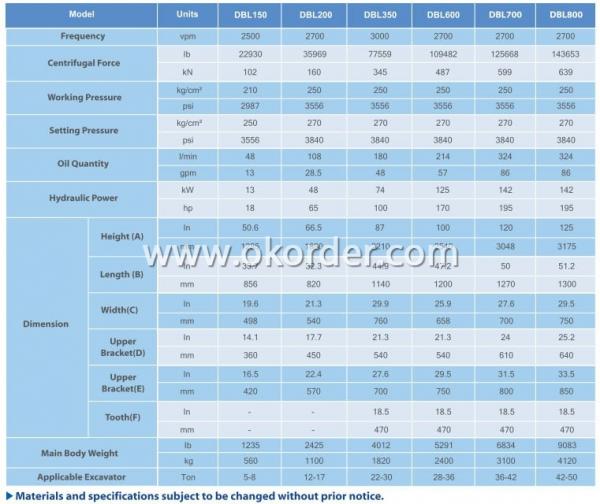

(DBL Series ) DBL150, DBL200,DBL350,DBL600,DBL700,DBL800

Patent Status

-World Patent PCT No.KR2007/004427

-U.S.A Patent No.12/673,152

-European Patent No.07 808 218 7

-Korea Patent No.10-0755017, No.10-0878296

-Innovative, Reliable Original Vibro Ripper in The World!

-Powerful digging force by special vibration structure

-Noiseless & Eco-friendly Vibrating Ripper

-No scattering of debris during digging operation

-Higher Production & efficiency

-Noiseless and eco friendly equipment (approx. 52~65dB lower than an equivalent hammer)

-Up to double and three times of productivity compared with an equivalent hydraulic hammer

-Easy installation to excavator with breaker hydraulic lines

-Utilizes 2,700rpm of high frequency vibration

-Patented heavy duty of elastomers(cushion elastomer) insolates the excavator from vibration shock

-Mounting and dismounting with 5~40 ton excavator boom at any time easily

-Innovatively designed tooth & pin have improved the durability

-Powerful breaking performance by high frequency motor

-Innovative technology, more powerful vibration and less noise level than ever

-Increased life time for the equipment by applying the oil rotation power system

-Developed with a patented high frequency vibration technology world first, which makes it in 80% of job site more productive than any rock breaker.

-Application area : it can work in tunnels, road extension section, public grievance, downtown, foundations, muddy, wet zone and under water places

Technical Specification of Korean Excavator Vibro Attachment

- Q: With the hd62 hammer machine, the last three strikes are 10 strikes, and the control is within 5 centimeters. Is that the height of the hammer fall?

- Depends on what pile you're playing. How big is it?. High strength prestressed pipe pile is about 300 if the drop is 1.8-2.0 meters, hammering 2CM (can slightly relax, because 62 300 large heavy hammer hammer); high strength prestressed pipe pile is about 400-600 if the drop is 1.8-2.0 meters, hammering 2CM.

- Q: What is the power of the pile driver?

- We produce crawler pile driving machines with a power of 57KW.

- Q: Highway guardrail, piling machine, drilling, piling price

- Highway guardrail, piling machine, drilling, piling price8-10 contact me

- Q: What's the difference between a pile driver and a boring pile driver?

- Piling can be static pile (precast pile) and other piles; drilling is what we call bored piles and mixing piles

- Q: How many hours will it take for the 200 piles and the 1 pile drivers?

- 200 piles of 1 piling machine is generally need 19 day time is finished, also need 152 hours to complete.

- Q: How much is piling foundation for pile driving machine?

- Piling machine prices from more than ten million to millions of, and the specific depends on how big you hit the pile, the specific configuration. Selection of models requires selection according to use.

- Q: What are the types of construction piling? What are the characteristics?

- Pile foundation treatment has many ways, but according to the current market situation and the country's strict requirements for the foundation, many processes are not applicable, such as manual excavation, etc., the following are common and common process methods.According to backfill points: commonly used are lime soil pile, plain soil pile, cement pile, garbage pile and so on.According to the backfill compaction type: clamping rod hammer compaction, heavy hammer compactionAccording to the hole forming process: the diesel hammer is immersed in the hole, the spiral drilling hole, and the Luoyang shovel holeIn accordance with the general classification of hole forming and compaction type: diesel hammer hole clamping hammer tamping hole; diesel hammer tamping; spiral drilling tamping (DDC); Luoyang shovel hole tamping and spiral drilling concrete pile (CFG). And what you say, pipe pile and fish, hammer, strong rammer are also belong to composite foundation. Among them, the pipe pile is divided into static pressure pile (suitable for static pressure machine into the ground) and diesel hammer pipe pile (diesel hammer directly into the ground).Several of the above are mainly to eliminate collapsibility and increase the composite bearing capacity, which belong to composite foundation.

- Q: Demolition houses use pile driving machines to smash the cement columns and cause great noise. Which department can I complain to?

- 2, construction noise (refers to the construction process caused by interference surrounding the living environment sound)3, traffic noise (refers to motor vehicles, railway locomotives, motor vehicles, aircraft and other means of transport in the operation of the interference caused by the surrounding living environment sound)Three, in addition, industrial noise and construction noise pollution can be complained to the municipal environmental protection bureau.Four, the noise pollution caused by traffic can be complained to the specific functional departments.1 if the motor vehicle does not use the acoustic device in accordance with the regulations, the local public security organ shall give a warning or impose a fine on the basis of the circumstances.2. If a mobile vessel has any illegal acts of noise, the harbour superintendency administration shall give a warning or impose a fine in accordance with the circumstances.3 if the railway locomotive has any illegal acts of noise, the competent department of railways shall give administrative sanctions to the person responsible for it.However, around your environment if there is noise pollution, affecting the lives of the residents, the public can directly call 110 to report to the 110 command center will be based on public security, urban management, environmental protection departments issued instructions, asked relevant departments to exercise the functions of personnel.Hope to adopt, thank you.

- Q: What machinery is suitable for a PV pile driver?

- Are you talking about a small hammer pile driver for excavators? If you are playing a photovoltaic pile (hollow pipe pile) below 9 meters, you can use the north Yi Machinery BY-YH250 model of small hammer piling machine, installed on excavators.

- Q: What is the noise of a static pile and a diesel pile driver?

- The noise of the static pile is small, so it is suitable for the construction in the city and the construction cost is higher.

1. Manufacturer Overview

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Korean Excavator Vibro Attachment

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Sets set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords