Pile Driver (DPD Fixed Clamp Type Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Pile Driver (DPD Fixed Clamp Type Series)

-Proven economic feasibility, mobility, safety

-360 degrees rotation devices of middle brackets

SHEET PILE DRIVER (GENERAL TYPE)

DPD Fixed Clamp Series - DPD350

- 360 degrees rotation of middle bracket

- Proven economic feasibility, mobility, safety

- Driving & Extraction sheet pile, tube, H-beam

- Most representative hydraulic vibro hammer

- Suitable equipment for construction working site

Excellent performance and mechanisms without power pack.

Proven workability: With the advantage of the excavator’s mobility, High performance operation at overpasses, under high voltage lines, on bridges and populated cities.

-Maximized the life of the equipment by using a special bearing designed for high frequency

-Best quality of Cushion elastomers are adopted in order to isolate vibration being transmitted to excavator.

-Easy installation using breaker hydraulic line of the excavator with electric cable device and operation control

-Mounting and dismounting can be easily done at all times

-The upper body allows 360 degree free rotation for easy operation and automatically anchors itself during operation

-Sheet pile, H beam and tube can be used by hooking up a wire on the main body of pile driver

-Double clamping devices can be fitted for pipe driving and extracting (Option)

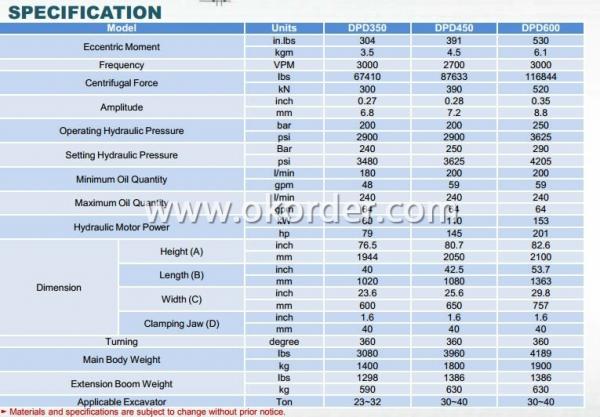

Specification of Pile Driver (DPD Fixed Clamp Type Series)

- Q: What kind of pile driver, rotary drilling machine can drill under medium weathering rock layer?

- The Xugong power head, wylong machinery mechanical lock rod rotary drilling rig Yuchai engine and can be weathered rock and sediment layer in the layer below, backfill soil drilling construction

- Q: What are the characteristics of hydraulic static piling compared with traditional pile driver?

- No nuisance, you can work in the downtown area

- Q: Can you drive an excavator? Can you learn it quickly?

- What you said is the steel sheet pile hammer shock, will not have to open the machine learning

- Q: Principles of piling

- The structure of a pile driver consists of a pile hammer, a pile stand and auxiliary equipment. The pile hammer is attached to two parallel vertical guide rods (commonly called Longmen) at the front of the pile support and hoisted with lifting hooks. The pile foundation is a steel structure tower with a windlass at the back of which is used to lift the pile and hammer. A guide frame consisting of two guide rods is used in front of the pile to control the direction of the pile driving so that the pile can be accurately penetrated into the formation in accordance with the design orientation. The tower and the guide frame can be used to batter pile deflection. The guide frame can also be extended downward along the tower and used to fetch water along the embankment or pier. The pile can move and move. The basic technical parameters of a pile driver are impact weight, impact kinetic energy and impact frequency. According to the motion of the pile hammer power source can be divided into hammer, hammer, diesel hammer, hydraulic hammer etc..

- Q: What type of machine is needed for highway foundation piling machine? Price?

- W-1001 excavators need to be refitted with a hammer weight of 2 tons and a depth of 20 meters,

- Q: What kind of industry can use a pile driver?

- Pile driver: economic development, led to the rapid development of the industry, especially in recent years, urban and rural areas and highways, railways, power stations and other construction to accelerate the development of pile machinery. Such as our factory production of this kind of pile machinery, more subdivision, more widely used.?Piling machine basically can be divided into hydraulic piling machine, foundation piling machine, piling machine, photovoltaic power plant hammer piling machine, hammer piling machine and four kinds of diesel hammer piling machine. Each kind of work principle is not the same.

- Q: What are the types of construction piling? What are the characteristics?

- Pile foundation treatment has many ways, but according to the current market situation and the country's strict requirements for the foundation, many processes are not applicable, such as manual excavation, etc., the following are common and common process methods.According to backfill points: commonly used are lime soil pile, plain soil pile, cement pile, garbage pile and so on.According to the backfill compaction type: clamping rod hammer compaction, heavy hammer compactionAccording to the hole forming process: the diesel hammer is immersed in the hole, the spiral drilling hole, and the Luoyang shovel holeIn accordance with the general classification of hole forming and compaction type: diesel hammer hole clamping hammer tamping hole; diesel hammer tamping; spiral drilling tamping (DDC); Luoyang shovel hole tamping and spiral drilling concrete pile (CFG). And what you say, pipe pile and fish, hammer, strong rammer are also belong to composite foundation. Among them, the pipe pile is divided into static pressure pile (suitable for static pressure machine into the ground) and diesel hammer pipe pile (diesel hammer directly into the ground).Several of the above are mainly to eliminate collapsibility and increase the composite bearing capacity, which belong to composite foundation.

- Q: Why is AMD's CPU name a pile driver or something?

- AMD's CPU micro architecture named "piling machine"".

- Q: Why do some people need to dig the foundation and pile it up to dig a hole?

- Digging foundation, piling and digging, piling are twoGenerally after the first pile driving, dig the foundation, you think, I pile is to pile machine back and forth, you dug the pit, how the machine down to pit how to walk, the foundation pit bearing capacity is not enough or the foundation pit is disturbed,

- Q: Can the piling machine be built at night?

- Able to function without affecting the residents' rest.

1. Manufacturer Overview

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pile Driver (DPD Fixed Clamp Type Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords