CMAX 680B-II Series Hydraulic Static Pile Driver for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX Series Hydraulic Static Pile Driver for Sale

ZYJ series hydraulic static pile driver is the product for building pile foundation construction under the independent research and development of our company and with more than 10 national patented technologies. It is a novel environmentally friendly construction equipment characterized by no pollution, no noise, no vibration, fast pressing of pile as well as high pile quality, and represents the development direction of piling machinery. Since mass production, its domestic market share has been firmly first, and our company has become a professional enterprise with research and development, production and sales of domestic pile machine taking the lead. The product won the second prize of the State Scientific and Technological Progress Award in 2003, becoming the famous-brand product of Hunan. Our company participated in drafting the Hydraulic Pile Driver industrial standard (JB/T11674 2013), which greatly promotes the development and progress of technology of static pile driver and pipe pile industry in China. Our company completed the upgrading of product design in 2013 to comprehensively improve the configuration, performance and quality, and the products are well welcomed and praised by the customers since it was put on the market.

Feature:

1. High-efficiency and energy-saving piling system with quasi constant power

2. Humanized driver cab and concise and clear control console

3. Piling oil cylinder and motor pump set with scientific and reasonable matching

4. Patented technology - fast return of piling oil cylinder

5. Clear and simple hydraulic piping layout

6. Patented technology - multipoint pressure-equalizing gripper mechanism

7. Unique "side piling and angle piling" device

8. Steel H-shaped pile can be pressed into the trapezoidal and triangular piles according to customer requirements.

9. Simple structure and easy transport

10. New hydraulic walking chassis

11. New patent – side piling device

| Parameter | ZYJ680B-II | |

|---|---|---|

| Dimension | Length mm | 14000 |

| Width mm | 8400 | |

| Height mm | 2980 | |

| tf Max.piling force | 680.5 | |

| m/min Max.piling speed | 13.6 | |

| Travel Capacity | Lengthwise m | 3.6 |

| Widthwise m | 0.7 | |

| Angel ° | 8° | |

| Standard crane model | QY16C | |

| Grounding Pressure | (Kpa)Long ship | 119 |

| (Kpa)Short ship | 158 | |

| Side pile distance mm | 600 | |

| Comer pile distance mm | 1100 | |

| Max round pile mm | 6016/Y60F45 | |

| Max square pile mm | 6032/Y60F60 | |

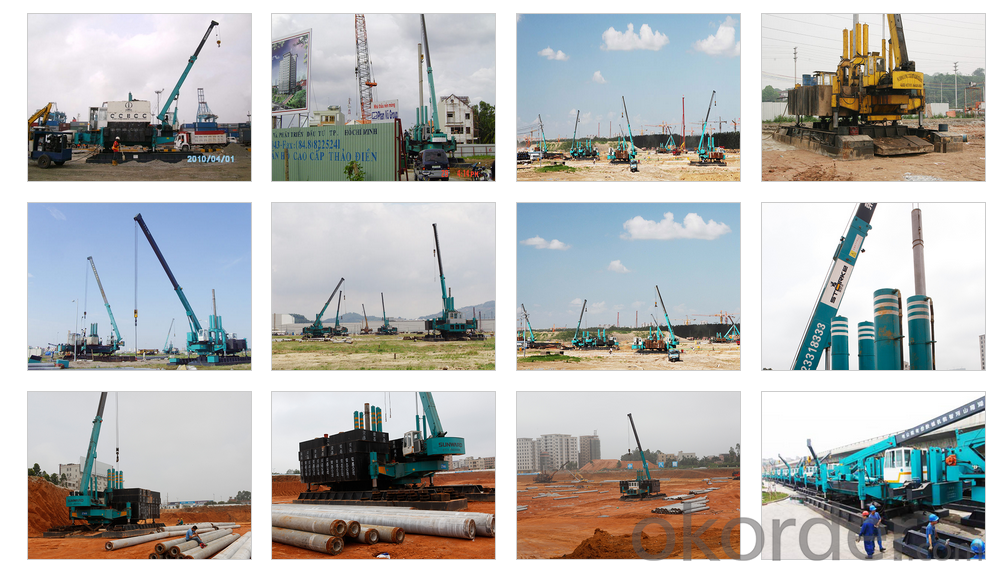

Cases

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

- Q: Will the crawler auger / pile driver dig out the soil and put it aside or can it be removed far away?

- According to the length of the pole of the pile driver, the distance is different.

- Q: Which is better, wheel driven pile driver or caterpillar rotary drilling rig? What's the difference between workmanship?

- Wheeled come and go convenience, crawler effect is better!

- Q: What's the difference between a walking tube type diesel pile driver and a track type diesel pile driver?

- The piling machine works on the top and bottom of the pile hammer. The pile hammer moves up and down on the 2 rail. It is called a track type diesel pile driver, and the pile hammer operates in the pipe way up and down. It is called a tube type diesel pile driver

- Q: What is the power of the pile driver?

- Hello, there are many kinds of power in the pile driver. How big do you need?.

- Q: Diesel hammer piling machine principle

- Diesel pile hammer body is made of cylinder and plunger, similar to the working principle and the single cylinder two stroke diesel engine into the cylinder combustion under high temperature and high pressure atomized diesel combustion chamber by injection pressure generated by the detonation driven hammer working. According to the structural form of diesel hammer rod and cylinder type separation.

- Q: Is the prestressed pipe pile driven by a diesel pile driver or a static pile driver?

- Static pressure, relatively environmental protection, no noise, mainly hydraulic system static pressure pipe sinking.We also work in the field of pile foundation engineering! 138 (bored pile) 781 (punching pile), 95 (precast pipe pile), 909 (high pressure jet grouting) (mixing pile) (anchor bolt, anchor rope) (slope foundation pit support) foundation treatment. Over the phone up housing construction, bridge pile foundation construction!

- Q: What are the types of construction piling? What are the characteristics?

- Pile foundation treatment has many ways, but according to the current market situation and the country's strict requirements for the foundation, many processes are not applicable, such as manual excavation, etc., the following are common and common process methods.According to backfill points: commonly used are lime soil pile, plain soil pile, cement pile, garbage pile and so on.According to the backfill compaction type: clamping rod hammer compaction, heavy hammer compactionAccording to the hole forming process: the diesel hammer is immersed in the hole, the spiral drilling hole, and the Luoyang shovel holeIn accordance with the general classification of hole forming and compaction type: diesel hammer hole clamping hammer tamping hole; diesel hammer tamping; spiral drilling tamping (DDC); Luoyang shovel hole tamping and spiral drilling concrete pile (CFG). And what you say, pipe pile and fish, hammer, strong rammer are also belong to composite foundation. Among them, the pipe pile is divided into static pressure pile (suitable for static pressure machine into the ground) and diesel hammer pipe pile (diesel hammer directly into the ground).Several of the above are mainly to eliminate collapsibility and increase the composite bearing capacity, which belong to composite foundation.

- Q: How do I maintain the hydraulic pile driver I bought?

- the workload of the project; the geographical environment of the project; and the price the boss expects.

- Q: Clean the dirt and grease piling machine how much money

- The pile foundation is a steel structure tower with a windlass at the back of which is used to lift the pile and hammer. A guide frame consisting of two guide rods is used in front of the pile to control the direction of the pile driving so that the pile can be accurately penetrated into the formation in accordance with the design orientation.

- Q: How can I find a pile driver?

- Go to the construction site, it is better to have known the construction team, or the construction company pull!

Send your message to us

CMAX 680B-II Series Hydraulic Static Pile Driver for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords