Anti Static Strap

Anti Static Strap Related Searches

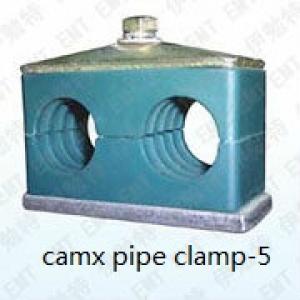

Anti Static Anti Static Band Anti Static Sponge Anti Static Cover Anti Static Rug Stainless Steel Strap Vinyl Anti Static Anti Static Paint Anti Static Work Mat Stainless Steel Straps Anti Static Tiles Anti Static Workbench Mat Anti Static Floor Paint Stainless Steel Ratchet Strap Anti Static Mats For Electronics Esd Anti Static Mat Stainless Steel Ratchet Straps Stainless Steel Strut Stainless Steel Straw Stainless Steel Adhesive Stainless Steel Strips Stainless Steel Door Stop Stainless Steel Anti Seize Stainless Steel Scrap Aluminum Strip Stainless Steel Clamp Scrap Stainless Steel Stainless Steel Pipe Clamp Stainless Steel Straws Esd Wrist StrapAnti Static Strap Supplier & Manufacturer from China

Anti Static Strap is a crucial product designed to effectively dissipate static electricity, ensuring the safety of sensitive electronic components and equipment. It is widely used in various industries, such as electronics manufacturing, data centers, and cleanrooms, where static electricity can cause damage or malfunction. By grounding the user and their work environment, Anti Static Strap helps to prevent electrostatic discharge (ESD) incidents, which can be detrimental to the performance and reliability of electronic devices.The Anti Static Strap is typically worn around the wrist or attached to an ankle, and it is connected to a grounding point, such as a grounding mat or a grounding wire. This connection ensures that any static charge buildup is safely conducted away from the user and the sensitive components they are handling. In addition to its primary function, the Anti Static Strap is also used in conjunction with other ESD protection equipment, such as anti-static mats, wrist straps, and ionizing air guns, to create a comprehensive静电防护解决方案.

Okorder.com is a reputable wholesale supplier of Anti Static Strap, offering a large inventory of high-quality products at competitive prices. As a leading distributor in the ESD protection industry, Okorder.com is committed to providing customers with reliable and efficient solutions to meet their static control needs. With a wide range of Anti Static Strap options available, customers can choose the most suitable product for their specific application, ensuring optimal performance and protection against static-related issues.

Hot Products