Flexible Anti Static PVC Strip Curtains

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Flexible Anti-static PVC Strip Curtains

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

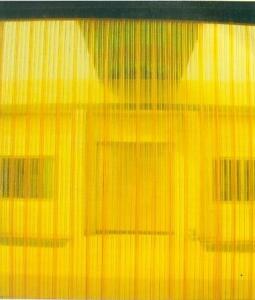

Applications of Flexible Anti-static PVC Strip Curtains

Widely used in electronics, food, pharmaceutical, refrigeration industry.

Can be used as barrier wall,protective portiere/curtain for sensitive area or protective cover for sensitive industry.

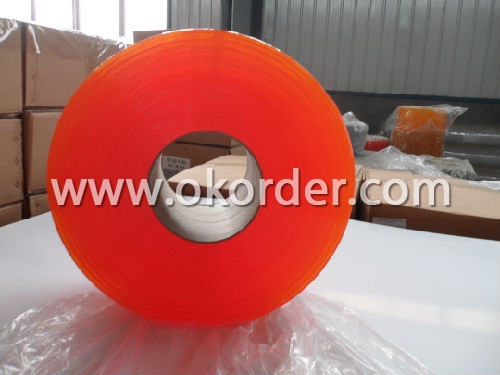

Package& Delivery of Flexible Anti-static PVC Strip Curtains

Wooden pallet,shirnk film according to custom requires.

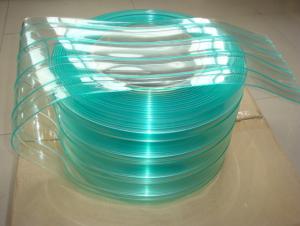

Colors of Factory-sale Flexible PVC Strip Curtains

Green,Clear.

Data sheet of Flexible Anti-static PVC Strip Curtains

Performance Text | Standard Clear Formula | Cold Formula | Super Polar Curtain | Unit |

Softness A Hardness | 75+-5 | 65+-5 | 65+-5 | / |

Brittle Point | Approx -35 | Approx -45 | Approx -45 | Degress C |

Falling Ball Test | -20 No Break | -40 No Break | -50 No Break | Degress C |

Flexibility | -20 No Break | -40 Bo Break | -50 No Break | Degress C |

Water Absorption | 0.20% | 0.20% | 0.20% | % |

Tensile Stress | 340 | 420 | 420 | % |

Rupture Resistance | >5 | >2 | >2 | N/mm |

Reaction to fire | Self-Extinguishing | Self-Extinguishing | Self-Extinguishing | 0 |

Flammability | Inflammable | Inflammable | Inflammable | 0 |

Airborne Insulation | ~35dB | ~35dB | ~35dB | 0 |

Light Transmission | >80 | >80 | >80 |

- Q: How do home appliance plastics impact the overall energy efficiency of the appliance?

- Home appliance plastics can have a significant impact on the overall energy efficiency of the appliance. The type and quality of plastics used in the manufacturing of home appliances can affect insulation properties, durability, and weight, all of which play a role in energy consumption. High-quality plastics with good insulation properties can help retain heat or cold, reducing the need for frequent energy use. Additionally, lightweight plastics can contribute to lighter appliances, reducing energy required for transportation and handling. Therefore, the choice of home appliance plastics is crucial in optimizing energy efficiency.

- Q: How does plastic contribute to the overall aesthetics of home appliances?

- Plastic contributes to the overall aesthetics of home appliances by providing a sleek and modern appearance. Its versatility allows for various shapes, sizes, and colors, enhancing the design and visual appeal of appliances. Additionally, plastic can be easily molded and textured to mimic other materials like metal or glass, creating a high-end look at a more affordable cost.

- Q: What are the common plastic components found in dishwashers?

- The common plastic components found in dishwashers include the tub or inner cavity, racks, silverware basket, spray arms, detergent dispenser, door latch, control panel, and various seals and gaskets.

- Q: What types of plastic are commonly used in refrigerator shelves and bins?

- The types of plastic commonly used in refrigerator shelves and bins are typically high-impact polystyrene (HIPS) and acrylonitrile butadiene styrene (ABS).

- Q: The production of plastic mold products when the head will break what reason is

- Plastic mold is the plastic processing industry and plastic molding machine matching, giving plastic products to complete configuration and precise size tools. Because of the plastic varieties and processing methods of various plastic molding machine and plastic product structure is simplified, so the plastic mold of the type and structure is various.

- Q: Are there any specific precautions to take when handling or installing plastic parts in home appliances?

- Yes, there are specific precautions to take when handling or installing plastic parts in home appliances. Some important precautions include avoiding excessive force or pressure while handling the parts to prevent cracking or damage, ensuring proper alignment and fitment during installation to avoid misalignment or potential leaks, and following the manufacturer's instructions and guidelines for installation to ensure proper functioning and safety. Additionally, it is important to keep the plastic parts away from excessive heat sources or direct sunlight, as extreme temperatures can cause warping or deformation of the plastic material.

- Q: Are there any specific transportation guidelines for plastic parts in home appliances?

- Yes, there are specific transportation guidelines for plastic parts in home appliances. These guidelines may vary depending on the specific appliance and its components, but generally, plastic parts should be securely packaged and protected during transportation to prevent any damage or breakage. This can include using appropriate cushioning materials, such as foam or bubble wrap, to provide shock absorption and prevent scratches. Additionally, it is advisable to ensure that plastic parts are well-secured within the appliance or its packaging to prevent movement or shifting during transportation. Following these guidelines will help ensure the safe and intact delivery of plastic parts in home appliances.

- Q: How do home appliance plastics impact the overall noise level of the appliance?

- Home appliance plastics can significantly impact the overall noise level of the appliance. Plastics that are not properly engineered or of low quality can transmit and amplify vibrations, resulting in increased noise levels. On the other hand, high-quality plastics with sound-dampening properties can help reduce vibrations and minimize noise, resulting in a quieter operation of the appliance. Therefore, the choice of plastics used in home appliances is crucial in determining the overall noise level experienced by users.

- Q: How does plastic contribute to the overall energy consumption of home appliances?

- Plastic contributes to the overall energy consumption of home appliances in various ways. Firstly, the production of plastic itself requires a significant amount of energy, both in terms of raw material extraction and manufacturing processes. This energy consumption contributes to the overall carbon footprint of the appliance. Additionally, plastic components in appliances can impact their energy efficiency. For instance, if plastic parts are poorly insulated or have poor thermal properties, they can lead to energy loss and reduce the overall efficiency of the appliance. Furthermore, plastic packaging used for appliances can also contribute to energy consumption, as the production, transportation, and disposal of plastic packaging require energy inputs. Therefore, minimizing the use of plastic in appliance manufacturing and packaging can help reduce their overall energy consumption.

- Q: What are the considerations for using renewable or bio-based plastics in home appliances?

- There are several key considerations when using renewable or bio-based plastics in home appliances. Firstly, the sustainability aspect should be evaluated, including the source of the material, its production process, and its end-of-life disposal. Secondly, the performance and durability of these plastics should be assessed to ensure they meet the necessary standards for home appliances. Additionally, the cost and availability of renewable or bio-based plastics need to be considered, as they may impact the overall affordability and accessibility of the appliances. Finally, consumer perception and acceptance of these materials also play a role in determining their viability in home appliances.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1991 |

| Annual Output Value | US$ 1 Million - US$ 2.5 Million |

| Main Markets | 40.00% Southeast Asia 15.00% Mid East 10.00% South America 5.00% Southern Europe 5.00% Northern Europe 5.00% Western Europe 5.00% Oceania 5.00% Africa 5.00% Eastern Europe 5.00% North America |

| Company Certifications | ISO 9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Flexible Anti Static PVC Strip Curtains

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords