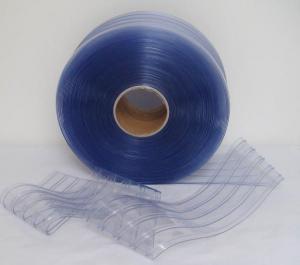

PVC Strip Door Curtain Used for Food Factory

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Best Selling PVC Strip Door Curtain

1. the CHEAPEST and the FASTEST solution to divide small or large rooms.

2.Strips: made of transparent or coloured plastic in full or partial overlap and are supported by fixed or sliding metal junctions.

3.can create real partion walls suitable to divide rooms and sheds.

4.a barrier against bugs and birds. they can be installed either in food or in pharmaceutical areas.

5.Suitable for LOW TEMPERATURES: -50 °C to -50 °C is also available.

6.Easy and quick to install and do not require any particular maintenance.

7.Solid or sliding track manufactured in either stainless or galvanized finishes.

8.This product is manufactured to suit the clear open specified by the client.

Applications of Best Selling PVC Strip Door Curtain

PVC flexible strip doors are widely used in the following area:

Door construction, lamellar doors

Trade and industry

Seperation of production and storage sites

Cold stores,cold store depots

Door area screening for cold stire vehicle

Coloured warning strips for industrial doors

As a view protection, also with frosted surfaces

Package& Delivery of Best Selling PVC Strip Door Curtain

Wooden pallet,shirnk film according to custom requires.

Colors of Best Selling PVC Strip Door Curtain

Blue, Green, Orange, White and Yellow.

Other colours are available on request.

- Q: Can plastic parts in food sealers become damaged or worn out over time?

- Yes, plastic parts in food sealers can become damaged or worn out over time. Continuous use, exposure to heat and moisture, and general wear and tear can cause the plastic components to deteriorate, resulting in reduced performance or complete failure of the food sealer.

- Q: What types of plastic are commonly used in oven knobs and controls?

- The types of plastic commonly used in oven knobs and controls are typically heat-resistant plastics such as polyamide (PA), known as nylon, and polyphenylene sulfide (PPS). These materials can withstand the high temperatures generated by ovens without warping or melting.

- Q: What are the typical lifespans of home appliance plastics?

- The typical lifespans of home appliance plastics vary depending on various factors such as the quality of the plastic, usage patterns, maintenance, and environmental conditions. However, on average, home appliance plastics can last anywhere from 5 to 15 years. It is important to note that regular maintenance and proper care can help extend the lifespan of these plastics.

- Q: How does plastic impact the overall ease of use of home appliances?

- Plastic plays a significant role in enhancing the overall ease of use of home appliances. Its lightweight nature makes appliances easier to handle and maneuver, allowing for effortless transportation and installation. Additionally, plastic components often contribute to the smooth operation of appliances, promoting ease of operation and reducing the effort required by users. The durability and versatility of plastic also contribute to the longevity of appliances, ensuring they maintain their functionality over time.

- Q: Can plastic parts in ovens and stoves withstand high heat?

- Yes, plastic parts in ovens and stoves can generally withstand high heat.

- Q: How does the chemical compatibility of plastic used in home appliances affect their resistance to corrosion?

- The chemical compatibility of plastic used in home appliances plays a crucial role in determining their resistance to corrosion. When the plastic is not chemically compatible with the substances it comes into contact with, it can lead to chemical reactions that corrode the appliance. On the other hand, if the plastic is chemically resistant to the substances it encounters, it acts as a protective barrier, preventing corrosion from occurring. Therefore, choosing the right plastic with good chemical compatibility is essential for ensuring the longevity and resistance to corrosion of home appliances.

- Q: Can plastic parts in air conditioners withstand exposure to UV rays?

- Yes, plastic parts in air conditioners are typically designed to withstand exposure to UV rays. They are made from materials that are UV resistant, which ensures their durability and prevents degradation or discoloration caused by prolonged exposure to sunlight.

- Q: What are the considerations for using biodegradable or compostable plastics in home appliances?

- When considering the use of biodegradable or compostable plastics in home appliances, several factors need to be taken into account. Firstly, it is important to assess the durability and strength of these materials to ensure they can withstand the demands and lifespan of the appliance. Additionally, the ability of biodegradable or compostable plastics to withstand heat, moisture, and various cleaning agents should be evaluated to ensure they can be used safely in home appliances. The availability and cost of these materials, as well as their compatibility with existing manufacturing processes, should also be considered. Lastly, the environmental impact of using these plastics, both in terms of their production and disposal, should be carefully assessed to ensure they align with sustainability goals.

- Q: Can plastic parts in home appliances be affected by UV radiation?

- Yes, plastic parts in home appliances can be affected by UV radiation. Exposure to UV radiation can cause the plastic to degrade, become brittle, and discolor over time. Therefore, it is important to protect plastic parts from direct sunlight or use UV-resistant coatings to minimize the impact of UV radiation.

- Q: What are the main cost considerations when using plastic parts in home appliances?

- The main cost considerations when using plastic parts in home appliances include the cost of raw materials, manufacturing processes, tooling and molds, and any necessary customization or design changes. Additionally, the cost of quality control, testing, and compliance with regulatory standards should also be taken into account.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

PVC Strip Door Curtain Used for Food Factory

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches