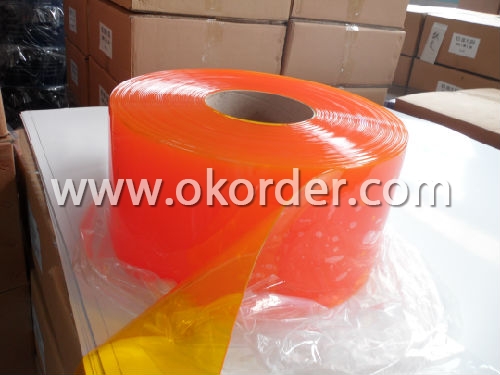

PVC Strip Doors in High Quality

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 sets roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Clear Flexible PVC Strip Curtain For Coldroom

1. the CHEAPEST and the FASTEST solution to divide small or large rooms.

2.Strips: made of transparent or coloured plastic in full or partial overlap and are supported by fixed or sliding metal junctions.

3.can create real partion walls suitable to divide rooms and sheds.

4.a barrier against bugs and birds. they can be installed either in food or in pharmaceutical areas.

5.Suitable for LOW TEMPERATURES: -50 °C to -50 °C is also available.

6.Easy and quick to install and do not require any particular maintenance.

7.Solid or sliding track manufactured in either stainless or galvanized finishes.

8.This product is manufactured to suit the clear open specified by the client.

Applications of Clear Flexible PVC Strip Curtain For Coldroom

PVC flexible strip doors are widely used in the following area:

Door construction, lamellar doors

Trade and industry

Seperation of production and storage sites

Cold stores,cold store depots

Door area screening for cold stire vehicle

Coloured warning strips for industrial doors

As a view protection, also with frosted surfaces

Package& Delivery of Clear Flexible PVC Strip Curtain For Coldroom

Wooden pallet,shirnk film according to custom requires.

Colors of Clear Flexible PVC Strip Curtain For Coldroom

Blue, Green, Orange, White and Yellow.

Other colours are available on request.

- Q: What are the considerations for using recycled plastic in home appliance components?

- Some considerations for using recycled plastic in home appliance components include the quality and purity of the recycled plastic, the compatibility of the plastic with the specific appliance component, the durability and strength of the recycled plastic, and the environmental impact of using recycled materials. It is important to ensure that the recycled plastic meets the required standards and does not contain any contaminants that could affect the performance or safety of the appliance. Additionally, the recycled plastic should be able to withstand the demands and stresses of the appliance component, ensuring its longevity and functionality. Lastly, using recycled plastic helps reduce waste and supports sustainability efforts, making it an environmentally conscious choice.

- Q: Are there any specific guidelines for disposing of home appliances with plastic parts?

- Yes, there are specific guidelines for disposing of home appliances with plastic parts. In most cases, these appliances should be recycled rather than thrown in the trash. Many communities have designated recycling centers or programs that accept plastic appliances. It is important to check with your local waste management authority or recycling facility for specific instructions on how to properly dispose of these items.

- Q: How can plastic parts in irons and steamers resist staining and discoloration from minerals in water?

- Plastic parts in irons and steamers can resist staining and discoloration from minerals in water due to a few reasons. Firstly, manufacturers often use high-quality, durable plastics that have inherent resistance to staining. These plastics are specifically chosen for their ability to withstand exposure to minerals and other chemicals found in water. Additionally, plastic parts can be treated with special coatings or additives that create a barrier between the plastic surface and the minerals, preventing them from penetrating and causing stains or discoloration. These coatings can provide an extra layer of protection and enhance the plastic's resistance to mineral buildup. Moreover, regular cleaning and maintenance of the iron or steamer can help prevent mineral buildup. Cleaning the plastic parts with mild soapy water or using specific cleaning solutions recommended by the manufacturer can remove any mineral deposits that may accumulate over time, keeping the plastic components stain-free and looking new. Overall, the combination of high-quality plastics, protective coatings, and proper cleaning practices helps plastic parts in irons and steamers resist staining and discoloration caused by minerals in water.

- Q: Can plastic parts in dishwashers withstand the constant exposure to steam and hot water during the drying cycle?

- Yes, plastic parts in dishwashers are designed to withstand constant exposure to steam and hot water during the drying cycle. They are made from heat-resistant materials that can withstand high temperatures without warping or melting. Additionally, dishwasher manufacturers subject their products to rigorous testing to ensure that plastic components can endure the extreme conditions of a dishwasher's drying cycle.

- Q: Are there any concerns with using plastic in appliances that require high precision?

- Yes, there are concerns with using plastic in appliances that require high precision. Plastic components may have limitations in terms of dimensional stability, heat resistance, and mechanical strength compared to metal counterparts. This can potentially impact the accuracy, durability, and reliability of precision appliances, especially those subject to high temperatures or mechanical stress. Additionally, plastic may have issues with wear, friction, or deformation over time, affecting the precision performance of the appliance. Therefore, careful material selection and engineering considerations are necessary to ensure optimal performance and mitigate any potential concerns with plastic components in high-precision appliances.

- Q: Can plastic parts in home appliances be affected by vibrations or shaking?

- Yes, plastic parts in home appliances can be affected by vibrations or shaking. Vibrations and shaking can cause stress and strain on the plastic components, leading to cracks, breakage, or even dislodging of the parts. Additionally, prolonged exposure to vibrations can weaken the structural integrity of the plastic, compromising the overall performance and longevity of the appliance. Therefore, it is important to handle and operate home appliances with care to minimize the impact of vibrations and shaking on their plastic parts.

- Q: How does the transparency or clarity of plastic parts in home appliances impact their visibility?

- The transparency or clarity of plastic parts in home appliances greatly impacts their visibility. When the plastic parts are transparent or clear, it allows users to easily see through them and observe the internal components or display features. This enhances visibility and makes it easier to monitor the appliance's operation or read any information displayed on it. On the other hand, if the plastic parts are opaque or less transparent, it may hinder visibility and make it more difficult to see the inner workings or read any information on the appliance. Thus, the transparency or clarity of plastic parts plays a crucial role in determining how easily users can observe and interact with their home appliances.

- Q: How does the impact resistance of plastic used in home appliances affect their durability?

- The impact resistance of plastic used in home appliances directly affects their durability. A higher impact resistance means that the plastic can withstand sudden impacts or accidental drops without cracking or breaking. This enhances the overall durability of the appliance, making it less prone to damage and increasing its lifespan. Conversely, lower impact resistance makes the appliance more vulnerable to damage from impacts, reducing its durability and potentially leading to premature failure.

- Q: How can plastic parts in blenders and food processors resist corrosion from acids in foods?

- Plastic parts in blenders and food processors are typically made from corrosion-resistant materials such as polypropylene, polyethylene, or polycarbonate. These materials have inherent properties that make them resistant to acids commonly found in foods. Additionally, manufacturers often apply special coatings or additives to further enhance their resistance to corrosive substances. This combination of material selection and protective measures ensures that plastic parts can withstand the corrosive effects of acids in foods, making them suitable for use in blenders and food processors.

- Q: Are there any specific regulations regarding the use of plastic in home appliances for industrial purposes?

- Yes, there are specific regulations regarding the use of plastic in home appliances for industrial purposes. These regulations vary by country and region, but they typically focus on environmental considerations, safety standards, and product labeling requirements. They aim to minimize the use of hazardous substances in plastics, ensure proper disposal and recycling practices, and promote energy efficiency. Standards such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) are commonly applied to regulate the use of plastics in home appliances for industrial purposes.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

PVC Strip Doors in High Quality

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 sets roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches