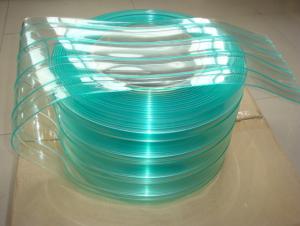

Anti Static PVC Strip Curtains

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Anti-static PVC Strip Curtains

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

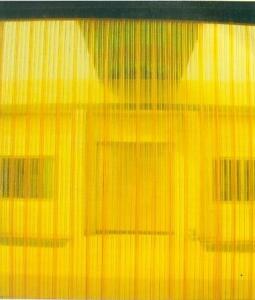

Applications of Anti-static PVC Strip Curtains

Widely used in electronics, food, pharmaceutical, refrigeration industry.

Can be used as barrier wall,protective portiere/curtain for sensitive area or protective cover for sensitive industry.

Package& Delivery of Anti-static PVC Strip Curtains

Wooden pallet,shirnk film according to custom requires.

Colors of Anti-static PVC Strip Curtains

Green,Clear.

Data sheet of Anti-static PVC Strip Curtains

Performance Text | Standard Clear Formula | Cold Formula | Super Polar Curtain | Unit |

Softness A Hardness | 75+-5 | 65+-5 | 65+-5 | / |

Brittle Point | Approx -35 | Approx -45 | Approx -45 | Degress C |

Falling Ball Test | -20 No Break | -40 No Break | -50 No Break | Degress C |

Flexibility | -20 No Break | -40 Bo Break | -50 No Break | Degress C |

Water Absorption | 0.20% | 0.20% | 0.20% | % |

Tensile Stress | 340 | 420 | 420 | % |

Rupture Resistance | >5 | >2 | >2 | N/mm |

Reaction to fire | Self-Extinguishing | Self-Extinguishing | Self-Extinguishing | 0 |

Flammability | Inflammable | Inflammable | Inflammable | 0 |

Airborne Insulation | ~35dB | ~35dB | ~35dB | 0 |

Light Transmission | >80 | >80 | >80 |

- Q: What are the considerations for using recycled content in home appliance plastics?

- There are several considerations when using recycled content in home appliance plastics. Firstly, the quality and consistency of the recycled material need to be assessed to ensure it meets the required standards and performance criteria. Secondly, the compatibility of the recycled content with the manufacturing process and other materials used in the appliance must be considered. Additionally, the environmental impact of sourcing and processing the recycled material should be evaluated to ensure it aligns with sustainable practices. Lastly, the cost-effectiveness and market demand for appliances with recycled content should be taken into account to determine the feasibility of incorporating recycled materials.

- Q: How does the choice of plastic affect the performance of a home appliance?

- The choice of plastic can greatly impact the performance of a home appliance. Different types of plastics vary in their durability, heat resistance, and electrical insulation properties. The selection of a suitable plastic can ensure the appliance withstands wear and tear, operates efficiently in high-temperature conditions, and prevents electrical hazards. Inadequate plastic choices may result in reduced lifespan, poor thermal management, and safety issues, ultimately affecting the overall performance and reliability of the appliance.

- Q: Can plastic parts in home appliances be easily replaced with alternative materials?

- Plastic parts in home appliances can be replaced with alternative materials, but it may not always be easy. The design and functionality of the appliance need to be taken into consideration when choosing a suitable alternative material. Additionally, alternative materials may require modifications to the appliance's structure or components, making the replacement process more complex. However, advancements in materials science and manufacturing techniques are continually providing more options for replacing plastic parts in home appliances with eco-friendly and sustainable alternatives.

- Q: Do plastic home appliances emit any odors?

- Yes, plastic home appliances can emit odors, especially when they are new. This is due to the off-gassing of volatile organic compounds (VOCs) that are released by the plastic materials used in their construction. However, these odors typically dissipate over time and with proper ventilation.

- Q: Are there any specific guidelines for cleaning home appliances with plastic parts?

- Yes, there are specific guidelines for cleaning home appliances with plastic parts. It is recommended to avoid using harsh chemicals or abrasive cleaners as they can damage the plastic. Instead, use a mild detergent or a mixture of water and vinegar to clean the plastic parts. Additionally, it is important to avoid using abrasive scrub brushes or scrubbing pads that can leave scratches.

- Q: Can home appliance plastics be easily replaced with more sustainable alternatives?

- Yes, home appliance plastics can be easily replaced with more sustainable alternatives. With advancements in technology and increasing awareness about environmental concerns, manufacturers have been developing and using various sustainable materials such as bioplastics, recycled plastics, and plant-based alternatives. These alternatives not only reduce the reliance on non-renewable resources but also minimize the carbon footprint associated with the production and disposal of traditional plastics. Additionally, consumers are increasingly demanding eco-friendly products, which further encourages the industry to adopt more sustainable options for home appliances.

- Q: Are there any specific guidelines for cleaning or maintaining plastic parts in home appliances?

- Yes, there are specific guidelines for cleaning and maintaining plastic parts in home appliances. It is recommended to use mild soapy water and a soft cloth or sponge to clean the plastic surfaces. Avoid using abrasive cleaners or scrub brushes as they may cause damage. Additionally, it is important to regularly inspect and remove any dirt or debris from the plastic parts to prevent build-up and ensure proper functioning of the appliance.

- Q: What are the considerations for using UV-resistant plastic in outdoor home appliances?

- There are several considerations for using UV-resistant plastic in outdoor home appliances. Firstly, UV radiation from the sun can cause regular plastic to degrade and become brittle over time, leading to reduced durability and potential breakage. UV-resistant plastic, on the other hand, is designed to withstand prolonged exposure to sunlight without degrading, ensuring the longevity of the appliance. Additionally, UV-resistant plastic helps to maintain the aesthetic appeal of outdoor appliances as it prevents fading, discoloration, or yellowing caused by UV rays. Furthermore, using UV-resistant plastic in outdoor appliances provides protection against damage from other environmental factors like rain, humidity, and extreme temperatures. Overall, it is crucial to consider UV resistance when selecting materials for outdoor home appliances to ensure their functionality, durability, and visual appeal in the long run.

- Q: Can plastic parts in home appliances be easily repaired or replaced by consumers?

- Yes, plastic parts in home appliances can often be easily repaired or replaced by consumers. Many manufacturers provide instruction manuals or online resources that guide users in troubleshooting and replacing common plastic components. Additionally, there are numerous third-party suppliers that offer replacement parts specifically for home appliances, making it convenient for consumers to fix their appliances themselves.

- Q: Can plastic parts in electric woks release chemicals when exposed to heat?

- Yes, plastic parts in electric woks can release chemicals when exposed to heat.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Anti Static PVC Strip Curtains

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords