Pvc Strip Curtain Hardware

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 Sets set

- Supply Capability:

- 5 Containers Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

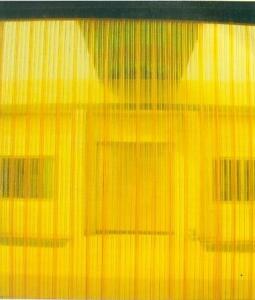

PVC Strip Curtain Hardware

Specifications of PVC Strip Curtain Hardware

1. Rail Size: 1m(length)x25px(thickness)

2. Clip Size:

150mm(w)x1mm(t)

200mm(w)x1mm(t)

300mm(w)x1mm(t)

Material: SS201,SS304,G.I

Application:

Applications of PVC Strip Curtain Hardware

One set of hanger include 3 ways

A. 1m rail, 8sets clips and 24 pcs screws, be applicable for 150mm and 200mm wide PVC strip

B. 1m rail, 6sets clips and 18 pcs screws, be applicable for 200mm and 300mm wide PVC strip

C. 1m rail, 4sets clips and 16 pcs screws, be applicable for 300mm and 400mm wide PVC strip

Package& Delivery of PVC Strip Curtain Hardware

Wooden pallet,Carton box according to custom requires.

Installation of PVC Strip Curtain Hardware

1.Cutting

Measure the size of door and cut the PVC strip curtain accordingly. Make sure the angle is 90 degree; Be carful with the cutter

2. Punch hole

a) Pushing holes in one side of PVC strip curtain

b) 200mm width door curtain need 3 holes

c) 300mm width door curtain need 4 holes

3. Install holders

a) Butt holders to the PVC strip with Screw.

b) Make sure the angle between strip and holders is 90 degree

4.Install hangers

Choose the best tool to punch hole according to the material of wall

- Q: How does plastic affect the overall reliability of home appliances?

- Plastic can both positively and negatively impact the overall reliability of home appliances. On one hand, plastic components in appliances can contribute to their durability by being lightweight, corrosion-resistant, and less prone to breakage. Additionally, plastic parts often help reduce costs, making appliances more affordable for consumers. However, excessive use of low-quality or cheap plastic materials can compromise the reliability of appliances, resulting in shorter lifespan, frequent repairs, and reduced performance. Therefore, the choice of plastic materials and their quality play a significant role in determining the overall reliability of home appliances.

- Q: Are there any concerns with using plastic in appliances that come in contact with food?

- Yes, there are concerns with using plastic in appliances that come in contact with food. Plastic can release harmful chemicals, such as bisphenol A (BPA) and phthalates, which can leach into the food and may pose health risks. Additionally, plastic can absorb odors and flavors from food, making it difficult to remove them completely. It is important to choose appliances made from food-grade or BPA-free plastic to minimize these concerns.

- Q: How does plastic contribute to the overall safety features of home appliances?

- Plastic contributes to the overall safety features of home appliances by providing insulation, shock resistance, and fire retardancy properties. It helps to prevent electrical shocks by insulating the wiring and components, reducing the risk of accidents. Plastic also absorbs shocks and impacts, protecting fragile internal parts and minimizing damage during transportation or accidental drops. Additionally, certain flame-retardant plastics are used to increase the fire safety of appliances, as they resist ignition and slow down the spread of flames in case of a fire.

- Q: Do plastic home appliances require any specific cleaning products?

- Yes, plastic home appliances may require specific cleaning products depending on the type of plastic, the appliance's surface, and the type of dirt or stain being cleaned. It's recommended to consult the manufacturer's guidelines or use mild, non-abrasive cleaners to avoid damaging the plastic.

- Q: What are the main factors that determine the scratch resistance of plastic parts in home appliances?

- The main factors that determine the scratch resistance of plastic parts in home appliances are the type and quality of the plastic material used, the surface treatment or coating applied, and the external forces or conditions the appliance is exposed to during use and handling.

- Q: Can home appliance plastics be easily repaired or replaced if they break or wear out?

- Home appliance plastics can often be easily repaired or replaced if they break or wear out. Many manufacturers provide replacement parts or offer repair services to ensure the longevity of their products. Additionally, there are various DIY repair kits and tutorials available that enable consumers to fix minor damages themselves. However, the ease of repair or replacement may vary depending on the specific appliance and the availability of parts.

- Q: Can home appliance plastics be transparent or translucent?

- Yes, home appliance plastics can be transparent or translucent.

- Q: How do plastic home appliances compare in terms of overall energy efficiency?

- Plastic home appliances generally have similar overall energy efficiency compared to their counterparts made from other materials. The efficiency of an appliance primarily depends on its design, technological advancements, and energy-saving features, rather than the material used. Therefore, plastic appliances can be just as energy-efficient as appliances made from other materials when they are developed with energy-saving mechanisms.

- Q: What are the considerations for using biodegradable or compostable plastics in home appliances?

- When considering the use of biodegradable or compostable plastics in home appliances, several factors need to be taken into account. Firstly, it is important to assess the durability and strength of these materials to ensure they can withstand the demands and lifespan of the appliance. Additionally, the ability of biodegradable or compostable plastics to withstand heat, moisture, and various cleaning agents should be evaluated to ensure they can be used safely in home appliances. The availability and cost of these materials, as well as their compatibility with existing manufacturing processes, should also be considered. Lastly, the environmental impact of using these plastics, both in terms of their production and disposal, should be carefully assessed to ensure they align with sustainability goals.

- Q: How does the use of plastic in home appliances contribute to energy conservation?

- The use of plastic in home appliances can contribute to energy conservation in a few ways. Firstly, plastic is a lightweight material, which means that appliances made with plastic components are generally lighter and easier to transport. This helps to reduce the energy required for transportation and ultimately lowers the carbon footprint associated with delivering the appliances to consumers. Additionally, plastic is an excellent insulator, which means that appliances can be designed with plastic parts to help retain heat or cold more efficiently. For example, plastic insulation in refrigerators and freezers can help to minimize energy loss and maintain optimal temperatures inside the appliances. This reduces the workload on the cooling system, leading to energy savings and increased efficiency. Furthermore, plastic is a versatile material that allows for innovative designs and shapes, enabling manufacturers to create more energy-efficient appliances. By using plastic in the construction of appliances, manufacturers can optimize the design to reduce energy consumption. For instance, plastic parts can be molded to fit perfectly, reducing air leakage and improving overall energy efficiency. Overall, the use of plastic in home appliances contributes to energy conservation by reducing transportation energy, improving insulation, and enabling the creation of more energy-efficient designs.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Pvc Strip Curtain Hardware

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 Sets set

- Supply Capability:

- 5 Containers Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords