Pvc Square Tube

Pvc Square Tube Related Searches

Rectangular Pvc Tube Clear Plastic Pvc Pipe Perforated Pvc Pipe Transparent Rubber Tube 40Mm Pvc Pipe Pvc Sign Plastic Poster Tube Plastic Coin Tubes Plastic Tube Slide Small Plastic Tubes Pvc Panel Door pvc tv stand Plastic Cigar Tubes Clear Packaging Tubes Plastic Document Tubes Red Plastic Tube Pvc Crimp Coatedwire Curved Plastic Tubing Pvc Fencing Clear Pvc Pipe 4 Inch Plastic Tube With Cap Rectangular Plastic Tubing Small Plastic Storage Tubes Pvc Down Ceiling Dip Tubes Pvc Walls and Ceilings Clear Plastic Shipping Tubes Poly Tube Netting Iron Tube Pvc CeilingsPvc Square Tube Supplier & Manufacturer from China

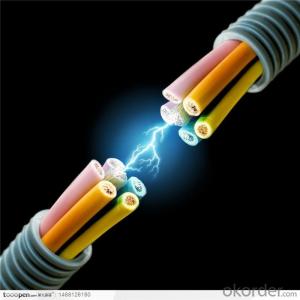

Pvc Square Tube, a versatile plastic piping solution, is widely recognized for its durability and resistance to corrosion. These tubes are made from polyvinyl chloride (PVC) and are designed in a square shape, making them suitable for a variety of applications. They are commonly used in construction, agriculture, and various industrial settings due to their ability to withstand harsh conditions while maintaining their structural integrity.The Pvc Square Tube is particularly useful in scenarios where a strong, lightweight, and flexible piping solution is required. It is often employed for tasks such as irrigation systems, electrical conduits, and protection for wiring in both indoor and outdoor environments. The square shape of the tube provides additional stability and support, making it an ideal choice for projects that demand a sturdy and reliable piping system.

Okorder.com is a leading wholesale supplier of Pvc Square Tube, boasting a vast inventory that caters to the diverse needs of customers across different industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Pvc Square Tube they provide meets the highest standards of performance and reliability. This makes them a trusted source for those seeking a dependable and cost-effective solution for their piping requirements.