Freezer Grade PVC Strips Rolls

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

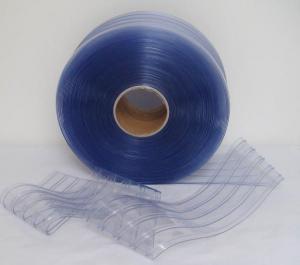

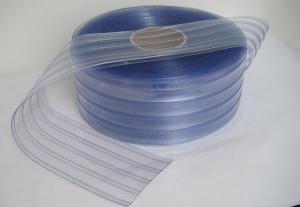

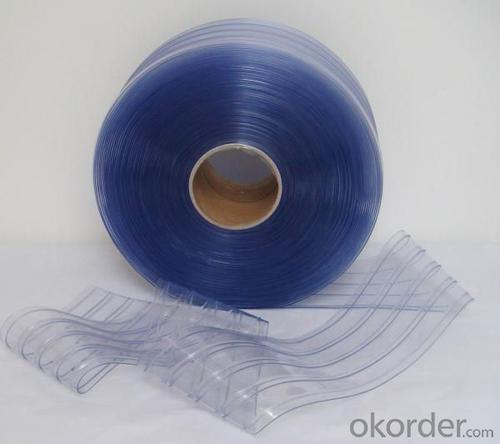

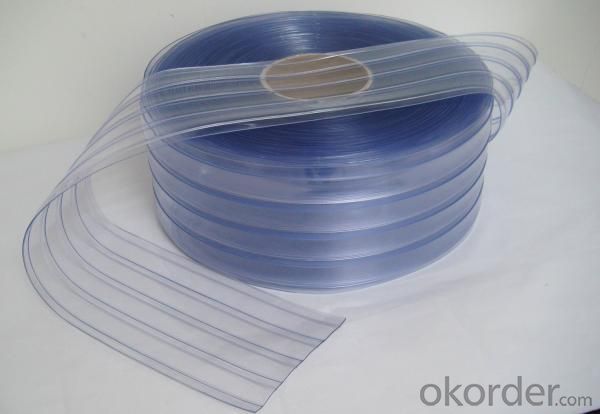

Specifications of High Quality Freezer PVC Strip Curtains

Application tempt range: -40℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

Applications of High Quality Freezer PVC Strip Curtains

Polar PVC strip curtain remain highly soft even at 40 Celsius below zero, allowing easy passing of people, vehicles and goods and effectively preventing loss of cold air. Polar PVC sheet is a good choice for save power because they do not contain electric drive. Polar door curtain do not have action component and do not produce noise during service. Cool strip has been designed from market experience and has been proved in independent tests to up to 50% of energy costs, while helping retail chill cabinets meet statutory temperature controls.

Polar grade PVC strip curtains are an option for Cold storage, Refrigerated doorways, Deli-Counters, Chiller Cabinets, Cold rooms and most retail refrigeration situations.

Package& Delivery of High Quality Freezer PVC Strip Curtains

Wooden pallet,shirnk film,cartons and according to custom requires.

Colors of High Quality Freezer PVC Strip Curtains

Polar door curtain are available in a range of colors, such like pale green, pale blue and clear. Blue is the most popular color in usages. If you used in the dark environment, just like cold rooms, clear color is the best choice for you.

Styles of High Quality Freezer PVC Strip Curtains

There are three styles of PVC strip curtain, Smooth, Single Ribbed and Double Ribbed. The door curtain used is dependent on the applications. PVC strips with raised ribbing on both sides are available offering improved durability enabling them to withstand repeated impact from heavy traffic such as forklift trucks.

- Q: Can home appliance plastics be easily recycled or reused?

- Yes, home appliance plastics can generally be easily recycled or reused. Many recycling programs accept various types of plastics used in home appliances, such as polypropylene and polystyrene. These plastics can be melted down and transformed into new products or used in the manufacturing of other plastic items. Additionally, some home appliances can be refurbished and resold, providing an opportunity for reuse. However, it is important to check with local recycling facilities and programs to ensure proper disposal and recycling methods are followed.

- Q: Are there any health concerns associated with plastic in home appliances?

- Yes, there are potential health concerns associated with plastic in home appliances. Some plastics may contain harmful chemicals such as phthalates and bisphenol A (BPA), which can leach into food or beverages when heated or stored for prolonged periods. These chemicals have been linked to various health issues like hormonal disruptions, developmental problems, and certain cancers. It is advisable to choose appliances made from BPA-free plastics or alternative materials like stainless steel or glass to minimize exposure to these potential health risks.

- Q: How does the new Juicer remove the plastic flavor of the fuselage?

- If it still smells, it'll have to wait.Acid is corrosive and may damage the coating on the surface of the machine. Please dilute it thoroughly before using it. It is not recommended.

- Q: How do home appliance plastics contribute to energy efficiency?

- Home appliance plastics contribute to energy efficiency by being lightweight, which reduces the energy required for transportation. Additionally, plastics are good insulators, helping to conserve energy by minimizing heat loss or gain. Moreover, plastic components in appliances can be designed to reduce friction, allowing for smoother operation and less energy consumption.

- Q: Are there any environmental concerns associated with the production of plastic used in home appliances?

- Yes, there are several environmental concerns associated with the production of plastic used in home appliances. The primary concern is the extensive use of fossil fuels, particularly in the form of petroleum, to manufacture plastics. This contributes to greenhouse gas emissions and exacerbates climate change. Additionally, the extraction of fossil fuels for plastic production often leads to habitat destruction and pollution of air, water, and land. Furthermore, the disposal of plastic appliances poses a significant challenge as most plastics are non-biodegradable and can persist in the environment for centuries, contributing to pollution, litter, and harm to wildlife.

- Q: Can plastic parts in humidifiers grow mold or bacteria?

- Yes, plastic parts in humidifiers can provide a suitable environment for the growth of mold and bacteria, especially if the humidifier is not cleaned and maintained regularly. The warm and moist conditions inside the humidifier can promote the growth of these microorganisms on the plastic surfaces, which can be detrimental to indoor air quality and potentially lead to health issues if inhaled.

- Q: Are there any health concerns associated with using plastic in home appliances?

- Yes, there are potential health concerns associated with using plastic in home appliances. Certain plastics, such as those containing bisphenol A (BPA) or phthalates, may leach harmful chemicals into food or drinks, especially when exposed to heat or acidic substances. These chemicals have been linked to various health issues, including hormonal disruptions, reproductive problems, and certain cancers. It is advisable to opt for BPA-free or phthalate-free plastics or consider alternatives like glass or stainless steel whenever possible to minimize these risks.

- Q: Are plastic home appliances resistant to electrical shocks or accidents?

- No, plastic home appliances are not inherently resistant to electrical shocks or accidents. However, manufacturers often incorporate safety measures such as grounding, insulation, and circuit protection to minimize the risks associated with electrical hazards. It is important to follow proper usage guidelines and handle these appliances with care to avoid accidents.

- Q: How does the use of plastic in home appliances impact the overall weight of the appliance?

- The use of plastic in home appliances generally reduces the overall weight of the appliance. Plastic is a lightweight material compared to other alternatives like metal, which helps make the appliance more portable and easier to handle.

- Q: Can plastic parts in home appliances be easily disassembled for maintenance or repairs?

- No, plastic parts in home appliances are typically not easily disassembled for maintenance or repairs.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Freezer Grade PVC Strips Rolls

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords