Large Rolls Of Plastic Sheeting

Large Rolls Of Plastic Sheeting Related Searches

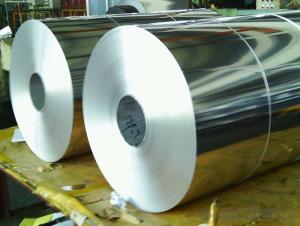

Colored Plastic Sheeting Rolls Protective Plastic Sheeting Garden Plastic Sheeting Large Plastic Panels Large Roll Of Aluminum Foil Big Roll Of Aluminum Foil 6 Mil Plastic Sheeting Large Aluminum Foil Sheets Blue Plastic Sheet Roll Structural Plastic Sheets Plastic Film Sheets Thin Hard Plastic Sheets Green Plastic Roofing Sheets 4 By 8 Plastic Sheets Clear Plastic Sheets Buy Sheet Plastic Flat Plastic Sheets High Temperature Clear Plastic Sheet Lightweight Plastic Sheets Plastic Sheets For Sale Stainless Steel Sheeting Hard Plastic Sheets 4X8 Fine Plastic Mesh Sheet Plastic Sheets 4X8 Plastic Coated Steel Roofing Sheets Wavy Plastic Sheets Heavy Duty Plastic Floor Covering Aluminum Sheet Metal Rolls Plastic Roll Hot Rolled Steel SheetLarge Rolls Of Plastic Sheeting Supplier & Manufacturer from China

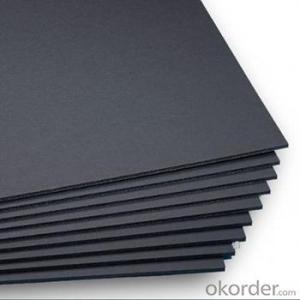

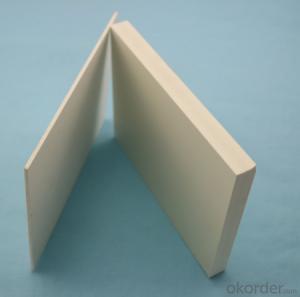

Large Rolls Of Plastic Sheeting encompass a variety of plastic materials such as polyethylene, PVC, and polypropylene, which are available in different thicknesses and sizes to cater to diverse needs. These sheets are highly versatile and can be used in numerous applications, including construction, agriculture, and event planning. They serve various purposes, such as providing waterproofing, protecting surfaces, and creating temporary barriers. Large Rolls Of Plastic Sheeting are also utilized in the creation of custom covers and liners for ponds, tanks, and other structures.In various industries, Large Rolls Of Plastic Sheeting are recognized for their durability and cost-effectiveness, making them a popular choice for a wide range of applications. Whether it's for ground protection at construction sites, creating a barrier to prevent weed growth in gardens, or providing a protective layer during events, these sheets offer a reliable solution. Okorder.com, as a wholesale supplier, prides itself on offering a vast inventory of Large Rolls Of Plastic Sheeting to meet the demands of different customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the products are available at competitive prices and are shipped promptly to maintain the high standards expected by their clients.

Hot Products