PVC Conveyor Belt with Skirt Sdewall,Cleat,PVC Rope

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt with Skirt Sdewall,Cleat,PVC Rope

We can divide the conveyor belt into three categories: PVC conveyor belt, PU conveyor belt and some special material, such as silica gel, rubber.

conveyor belt fabric layers: A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

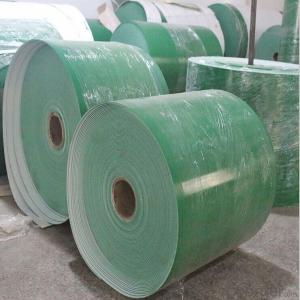

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

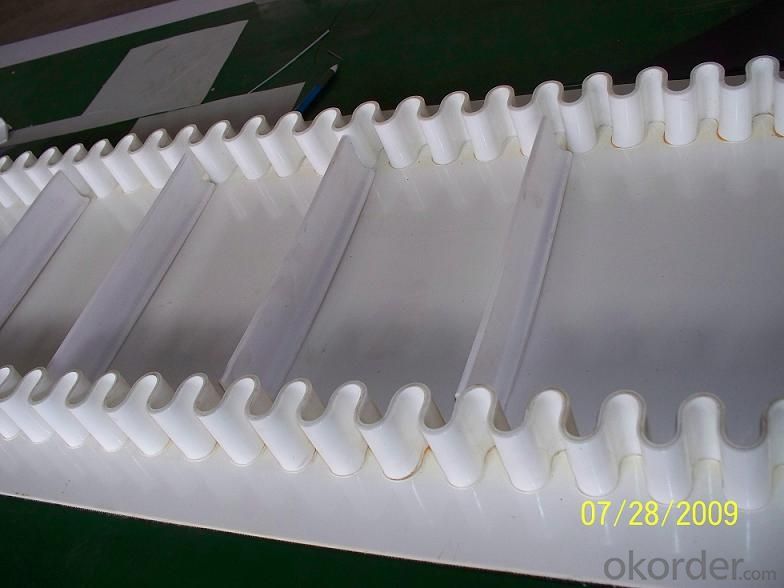

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

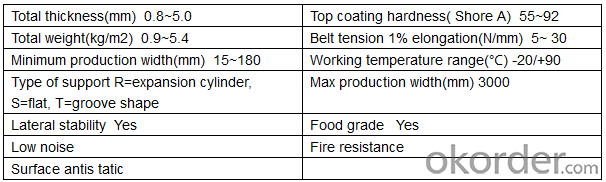

PVC Conveyor Belt Specification

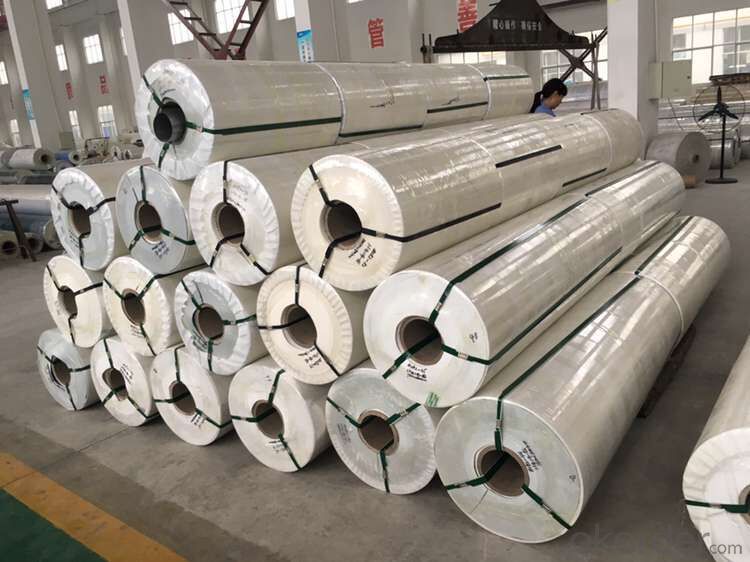

Packing and Shipping

1.Free for samples, Door-to-Door.

2. By Air or by Sea for batch goods, Airport/ Port receiving.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: In general,7-10days or based on customer's quantity.

Photos of PVC Conveyor Belt

FAQ

Can you give me discount?

Yes, of course. If you talk with us, you’ll get more.

Will you send me free sample?

Yeah, she'd love to; can you buy her a ticket?

Do you like to accept small orders?

We enjoy to grow up together with all our clients, whatever big or small.You will become bigger and bigger to be with us.

Buyer attention

If you are interested in our products and company, please leave a message here or E-mail to us, We will reply you without any delay.

- Q:EVA plastic products poisonous?

- EVA plastic products are non-toxic.Ethylene vinyl acetate copolymer, referred to as EVA. Ethylene vinyl acetate (VA) content in 5%-40%, and polyethylene (PE) compared to EVA due to the molecular chain of the vinyl acetate monomer, thereby reducing the high crystallinity, improved toughness, impact resistance, filler compatibility and heat sealing performance, is widely used in foam material, functional films, packaging mold, hot melt adhesive, wire and cable and toys and other fields.

- Q:Can olive nets be used in regions with a high bird population?

- Yes, olive nets can be used in regions with a high bird population. Olive nets are effective in protecting olive trees and crops from bird damage by creating a physical barrier that prevents birds from accessing the fruits. They are commonly used in areas with a significant bird population to deter them from feeding on the olives.

- Q:Can olive nets be used in olive groves with uneven terrain?

- Yes, olive nets can be used in olive groves with uneven terrain. Olive nets are versatile and can be adjusted to suit different terrains. They can be installed with support systems or adjusted by using stakes or other methods to accommodate the uneven ground. This ensures effective harvesting and protection of the olives, regardless of the terrain in the grove.

- Q:How many kinds of plastics are there?

- Foam plastics can be divided into three kinds of hard, semi hard and soft foam. Hard foam without flexibility, compression hardness is very big, only up to a certain stress deformation, stress the lifting of restitution; soft foam rich flexibility, compression hardness is very small, very easy to deformation, stress release after can restore the residual deformation small; semi rigid foam between flexibility and other properties between hard and soft foam.

- Q:Can olive nets be used in areas with strong UV radiation?

- Yes, olive nets can be used in areas with strong UV radiation. Olive nets are designed to protect the olive trees from various environmental factors, including UV radiation. They are made from materials that are resistant to UV rays and can effectively shield the trees from excessive exposure, helping to maintain their health and productivity.

- Q:Sponge does not belong to foam plastics

- There is a similarity between them, but the process is different and the uses are different.

- Q:How does an olive net affect the overall water usage in the olive grove?

- An olive net helps reduce overall water usage in an olive grove by preventing evaporation and retaining moisture in the soil.

- Q:Can olive nets be used in areas with high levels of air pollution?

- Yes, olive nets can be used in areas with high levels of air pollution. Olive nets are primarily used for protecting olive trees from birds and other animals, and they do not play a direct role in mitigating air pollution. However, they can still be effectively used in areas with high air pollution levels as long as they are properly maintained and cleaned regularly to prevent any contamination.

- Q:Are there any specific guidelines for using olive nets on dwarf or small-sized olive trees?

- Yes, there are specific guidelines for using olive nets on dwarf or small-sized olive trees. It is important to choose a net that is appropriately sized to cover the entire tree and secure it tightly to prevent any gaps. The net should be placed over the tree before the olives start ripening to protect them from birds and pests. It is advisable to periodically check the netting for any tears or damage and repair or replace it if needed. Additionally, the net should be removed after the harvest to allow for proper tree maintenance and prevent any potential damage.

- Q:Do olive nets require any special treatment before installation?

- Yes, olive nets usually require some special treatment before installation. It is important to ensure that the nets are clean and free of debris, as any dirt or leaves can affect their effectiveness. Additionally, the nets should be checked for any damages or tears and repaired if necessary. Proper storage and handling of the nets is also important to prevent any damage or tangling.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Conveyor Belt with Skirt Sdewall,Cleat,PVC Rope

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords