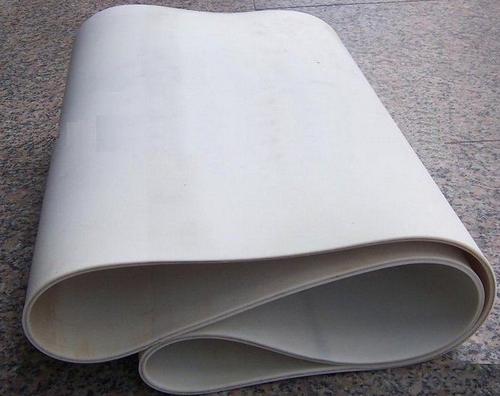

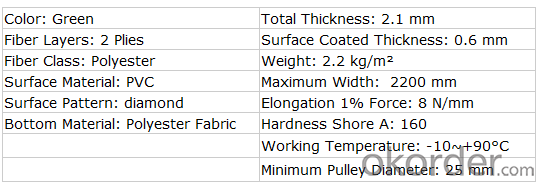

Treadmill PVC Conveyor Belt Good Elasticity Diamond Pattern

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

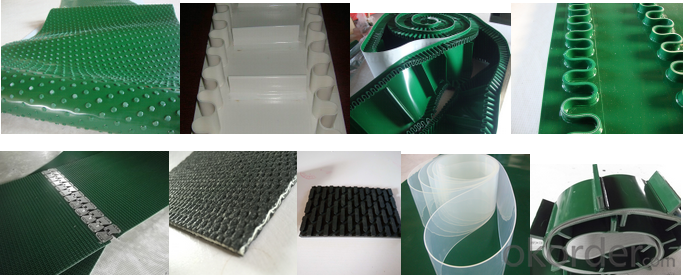

Good Elasticity PVC Conveyor Belt In Food Industr

PVC & PU Conveyor Belt

PVC conveyor belt in flexible construction provides high strength,low stretch characteristics, dimensional stability & are totally resistance to moisture, rot & mildew.

PVC Conveyor belt uses polyester fabrics as reinforcing materials, mainly used for conveying light, medium quality materials, suitable for use on the conveyor systems.

Description: 2mm Black PVC conveyor belt.

Top surface pattern is diamond . Two layers of nature fabric. Two layers of balck pvc glue.

Used for treadmill walking.

The maximun width: 4000mm

Temperature:-10℃~+80℃

Packaging & Shipping

1.Free for samples, Door-to-Door.

2. By Air or by Sea for batch goods, Airport/ Port receiving.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:Based on customers' quantity. In general,25 days for batch goods.

Product photos:

Pls contact me freely if any inquiry,thank you!

- Q: How do olive nets impact the overall texture of the olives?

- Olive nets help protect the olives from falling on the ground and getting damaged, which ultimately impacts the overall texture of the olives positively. By preventing contact with the soil, the nets prevent dirt and debris from adhering to the olives, maintaining their smooth and clean texture. Additionally, the nets provide shade and reduce exposure to direct sunlight, which can help prevent excessive dehydration and maintain the desired firmness and juiciness of the olives.

- Q: Can olive nets be used to extend the harvesting season?

- Yes, olive nets can be used to extend the harvesting season. These nets are commonly used in olive orchards to collect fallen olives during harvesting. By using olive nets, farmers can efficiently gather olives that have ripened and fallen from the trees, allowing them to extend the harvesting season and maximize their olive yield.

- Q: What types of plastics do you have?

- According to the molecular structure and thermal properties of synthetic resins in plastics, plastics can be divided into two types, thermoplastics and thermosetting plastics.(1) the characteristics of thermoplastics1) the resin molecules are linear or branched.2) softening when heating, when reaching a certain temperature, melting state, become a flow of viscous fluid, under certain pressure can be shaped into a certain shape, after cooling can maintain the shape has been formed. If heated again, it can be softened, melted and formed again and again.3) in the process of heating and cooling, it is mainly physical change, and in a few cases there are chemical changes.

- Q: Can olive nets be used to improve the profitability of olive farming?

- Yes, olive nets can be used to improve the profitability of olive farming. Olive nets are designed to protect the olives from pests, birds, and harsh weather conditions, thereby reducing crop loss and increasing the overall yield. By preventing damage to the olives, farmers can harvest a greater quantity of high-quality olives, which can then be used for various purposes such as olive oil production or table olives. This increased yield and improved quality can lead to higher profits for olive farmers, making olive nets a valuable investment.

- Q: Do olive nets affect the taste of the olives?

- Yes, olive nets can affect the taste of the olives. The nets are used to prevent the olives from falling to the ground and getting damaged. However, if the nets are not properly installed or maintained, they can cause moisture buildup, leading to mold or fungal growth, which can negatively impact the flavor of the olives. Additionally, if the nets are left on for too long, they can restrict air circulation and sunlight, affecting the ripening process and ultimately altering the taste of the olives.

- Q: EVA plastic products poisonous?

- Non-toxic。。For example, some foaming soles are also EVA. And foam gum, too.It seems that after foaming, it is more convenient to keep warm.I used to add EVA to LDPE as a drink straw, so I'm sure it's non-toxic.

- Q: What kind of plastic grade does polyether sulfone resin (PES) belong to?

- [heat resistance]The heat variant temperature is 200~220 DEG C, the continuous use temperature is 180~200 DEG C, and the UL temperature index is 180 DEG C.[water resistance]Up to 150 to 160 DEG C hot water or steam erosion at high temperatures from acid and alkali.[modulus of temperature, consul sex]The base modulus is almost unchanged at -100 to 200 degrees, especially above 100 DEG C, which is better than any of the thermoplastic resins.

- Q: White plastic products used for a long time and yellow, how do?

- Generally white white plastic in the injection molding to add whitening powder material, so that after the injection molding products will be white jade. After a period of time, the whitening powder will lose whitening effect under the action of sunlight, so it will make the product yellow.

- Q: What additives are used in plastics?

- The main requirements for plastic additives are: high efficiency: can effectively play its functions in the plastics processing and application. The comprehensive performance requirements should be based on the selection of additives mixing. The compatibility with synthetic resin better compatibility. The persistence: volatile in plastics processing and application process no exudation, does not migrate, dissolution. The chemical stability: no decomposition in plastics processing and application process, and the synthetic resin and other components of chemical reaction. The non-toxic, without any toxic effects on the human body. The price is low.

- Q: How do olive nets affect the overall antioxidant content of the olives?

- Olive nets have no direct impact on the overall antioxidant content of olives. The antioxidant content of olives is primarily determined by factors such as olive variety, growing conditions, and processing methods. Olive nets are mainly used to protect the olives from pests and birds during the ripening period, ensuring a higher yield and quality of olives, but they do not affect the antioxidant levels.

Send your message to us

Treadmill PVC Conveyor Belt Good Elasticity Diamond Pattern

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords