Cosmetic Aluminum Diamond Plate

Cosmetic Aluminum Diamond Plate Related Searches

Polished Aluminum Diamond Plate Colored Aluminum Diamond Plate Aluminum Diamond Plate Polish Diamond Plate Aluminum Polish Buy Aluminum Diamond Plate Aluminum Diamond Deck Plate Aluminum Diamond Plate Panels Anodized Aluminum Diamond Plate Polishing Aluminum Diamond Plate Polishing Diamond Plate Aluminum White Aluminum Diamond Plate Decorative Aluminum Plate Aluminum Diamond Plate Cabinets Aluminum Black Diamond Plate Aluminum Diamond Plate For Sale Cheap Aluminum Diamond Plate Aluminum Diamond Plate Material Aluminum Diamond Plate Strips Aluminum Sheet Diamond Plate Bending Aluminum Diamond Plate Fake Aluminum Diamond Plate Welding Aluminum Diamond Plate Sheet Aluminum Diamond Plate Diamond Plate Sheet Aluminum Aluminum Diamond Plate Roll Aluminum Diamond Plate Box Black Aluminum Diamond Plate Bright Aluminum Diamond Plate Painting Aluminum Diamond Plate Wholesale Aluminum Diamond PlateCosmetic Aluminum Diamond Plate Supplier & Manufacturer from China

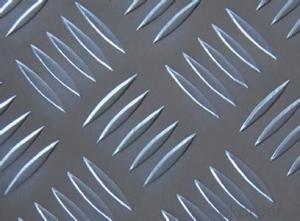

Cosmetic Aluminum Diamond Plate is a type of aluminum sheet material that features a diamond-shaped pattern on its surface, providing both aesthetic appeal and practical functionality. This product is widely used in the cosmetics industry for packaging and display purposes, offering a sleek and modern appearance that enhances the overall presentation of the products. The textured surface of the plate also adds grip and durability, making it an ideal choice for various cosmetic packaging applications.The usage scenarios for Cosmetic Aluminum Diamond Plate are vast, as it can be utilized in the production of makeup cases, compacts, lipstick tubes, and other cosmetic containers. Its unique design and sturdy construction make it a popular choice among manufacturers who are looking to create a high-quality, visually striking product. The material is also lightweight and easy to work with, allowing for efficient production processes and cost-effective solutions.

As a wholesale supplier, Okorder.com offers a large inventory of Cosmetic Aluminum Diamond Plate, ensuring that customers have access to the materials they need in a timely and cost-effective manner. With a commitment to quality and customer satisfaction, Okorder.com is a reliable source for businesses looking to incorporate this innovative material into their cosmetic packaging and display solutions.

Hot Products