Aluminum Trim Strips for Medicine Bottle Caps

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 500 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

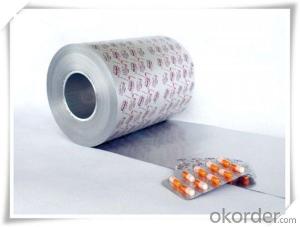

1.Description

Aluminum strip is widely used in Caps, especially for medicine bottle cap, because the good anti heat and anti wet and high elongation specification. it's very good for medicine bottle caps. Normally it's coated aluminum strip, coating thickness is around 4~5mic.

2.Specification and Application

Specification

| Alloy | 8011 |

| Temper | H12/ H14/ H16 |

| Process | DC |

| Thickness | 0.17~0.3mm |

| Width | As required |

| Core ID | As required |

Property

| Tensile strength | ≥100Mpa |

| Elongation | ≥2% |

| Tolerance of size | As GB Standard |

3. Advantages

We've been specialized in aluminium for more than ten years, we know this product very well, and we have good finacial support from government.

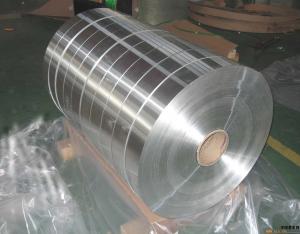

4. Pictures

5. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your minimum order quantity?

It's 3tons per size.

- Q: Is it possible to utilize recycled aluminum for the production of roofing materials for residential use?

- <p>Yes, you can use recycled aluminum to make roofing materials for your home. Recycled aluminum is not only environmentally friendly but also cost-effective. It maintains the same properties as new aluminum, making it suitable for various applications, including roofing. Recycled aluminum roofing materials are durable, lightweight, and resistant to corrosion, which are desirable qualities for any roofing system. However, it's important to ensure that the recycled aluminum is sourced from a reputable supplier to guarantee quality and safety.</p>

- Q: What are the potential safety hazards associated with the use of aluminum strips?

- <p>Aluminum strips are generally safe to use, but there are a few safety concerns to consider. They can be sharp and cause cuts if handled improperly. Additionally, aluminum dust, if inhaled, can cause respiratory issues. It's important to handle aluminum strips with care, wear protective gloves, and avoid inhaling dust. In the case of electrical applications, ensure that aluminum strips are properly insulated to prevent electrical shocks. Always follow safety guidelines and manufacturer instructions when using aluminum strips.</p>

- Q: What unique considerations must be taken into account when storing and transporting aluminum strip stock?

- <p>Yes, there are special requirements for storing and transporting aluminum strip stock. Aluminum is sensitive to moisture and can corrode, so it must be kept dry. It's also important to avoid scratches and dents, which can occur if the material is mishandled. Aluminum strip stock should be stored in a clean, dry environment, away from chemicals that could cause corrosion. When transporting, it should be secured to prevent movement that could lead to damage. Protective coverings or wrappings are often used to shield the material from the elements and potential physical impacts.</p>

- Q: What are the environmental regulations that impact the production and usage of aluminum strips?

- <p>Yes, there are several environmental regulations that affect the production and use of aluminum strips. These include regulations on emissions, waste disposal, and energy consumption. For instance, the European Union's Industrial Emissions Directive sets standards for emissions from aluminum production facilities. In the United States, the Environmental Protection Agency (EPA) enforces regulations such as the Clean Air Act and Resource Conservation and Recovery Act (RCRA), which impact how aluminum is produced and used. These regulations aim to minimize pollution, conserve resources, and promote recycling, thereby influencing the aluminum industry's practices globally.</p>

- Q: What is the standard thickness for aluminum strip roofing materials?

- <p>The recommended thickness for aluminum strip roofing varies depending on the specific application and local building codes. Generally, aluminum strip roofing is available in thicknesses ranging from 0.018 to 0.032 inches (0.46 to 0.81 mm). For residential applications, a thickness of 0.024 to 0.028 inches (0.61 to 0.71 mm) is commonly used, while commercial buildings might require a thicker strip, around 0.032 inches (0.81 mm) for added durability and longevity. Always consult with a roofing professional or follow local building codes to determine the appropriate thickness for your specific project.</p>

- Q: This question asks about the various color options available for aluminum strips.

- <p>Aluminum strips are available in a variety of colors to suit different applications and aesthetic preferences. Common colors include silver, which is the natural color of aluminum, black, white, and clear anodized. Additionally, they can be coated or anodized in other colors such as gold, bronze, blue, red, and green. Custom colors are also possible with specialized coating or anodizing processes. The choice of color can depend on the specific use of the aluminum strip, such as for decorative purposes, architectural applications, or industrial uses where color coding is required.</p>

- Q: What types of aluminum strips are known for their durability?

- <p>Yes, there are several types of aluminum strips known for their durability. One of the most durable types is 7075 aluminum, which is an alloy that offers high strength and is commonly used in aerospace applications. Another durable option is 6061 aluminum, which is a heat-treatable alloy with good mechanical properties and is often used in construction and transportation. Additionally, 3003 aluminum is known for its corrosion resistance and is used in applications where durability against weathering is important. The durability of aluminum strips can also be enhanced through various surface treatments and coatings.</p>

- Q: The user is asking if it is possible to apply paint or stain to aluminum siding after it has been installed.

- <p>Yes, you can paint or stain aluminum siding after installation, but it requires proper preparation. The surface must be thoroughly cleaned to remove any dirt, grease, or factory applied oils. A high-quality primer compatible with aluminum is essential before applying paint or stain. Use a paint or stain specifically designed for metal surfaces to ensure adhesion and durability. Always follow the manufacturer's instructions for the best results.</p>

- Q: Is it possible to use aluminum strips as a material for the exterior siding of a building?

- <p>Yes, aluminum strips can be used for exterior siding. They are known for their durability, resistance to weather, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and comes in various styles and colors, making it a popular choice for both residential and commercial buildings. It also has a long lifespan and can be recycled, adding to its environmental benefits. However, it's important to ensure proper installation and choose high-quality materials to maximize its performance and longevity.</p>

- Q: Is it possible to utilize recycled aluminum strips for construction purposes?

- <p>Yes, you can use recycled aluminum strips in your construction projects. Recycled aluminum is not only environmentally friendly but also cost-effective. It maintains the same strength and durability as new aluminum, making it suitable for various construction applications such as framing, roofing, and cladding. However, it's crucial to ensure that the recycled aluminum meets the required industry standards and specifications for your project to guarantee safety and performance. Always consult with a professional or engineer to confirm the suitability of recycled aluminum for your specific construction needs.</p>

Send your message to us

Aluminum Trim Strips for Medicine Bottle Caps

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 500 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords