Aluminum Wall Trim

Aluminum Wall Trim Related Searches

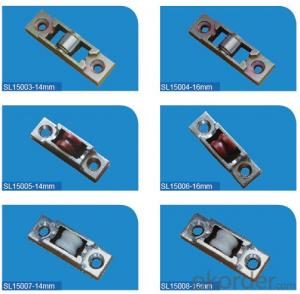

Aluminum Diamond Plate Trim Diamond Plate Aluminum Trim Trim Coil Aluminum Painting Aluminum Trim Coil Installing Aluminum Trim Coil Aluminum Wall Panels Aluminum Trim Coil Near Me Painted Aluminum Trim Coil Aluminum Trim Coil Roll Vinyl Trim Wood Grain Aluminum Trim Coil Aluminum Siding Trim Coil Aluminum Exterior Wall Panels Aluminium Curtain Wall Aluminum Wall Plate Best Aluminum Trim Coil White Aluminum Trim Coil Colored Aluminum Trim Coil Aluminum Trim Coil White Textured Aluminum Trim Coil Clay Aluminum Trim Coil Cutting Aluminum Sheet Drywall Trim Reveal Woodgrain Aluminum Trim Coil Aluminum Foil For Walls Poly Aluminum Trim Coil Alcoa Aluminum Trim Coil Pvc Aluminum Trim Coil Almond Aluminum Trim Coil Bending Aluminum Trim CoilAluminum Wall Trim Supplier & Manufacturer from China

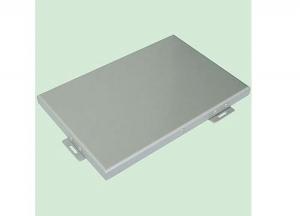

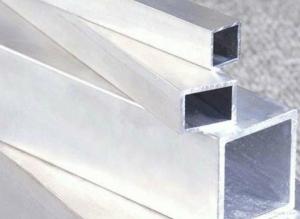

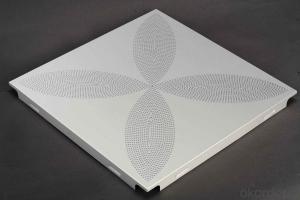

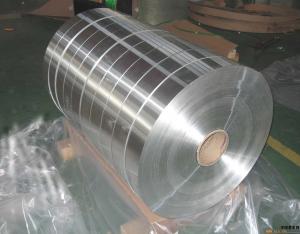

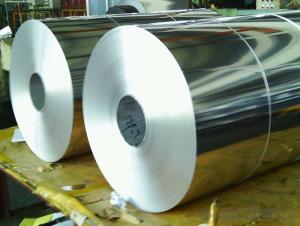

Aluminum Wall Trim is a versatile product made from high-quality aluminum material, designed to provide a sleek and modern finish to various interior and exterior surfaces. These trims are known for their durability, low maintenance, and resistance to corrosion, making them an ideal choice for both residential and commercial applications. They can be used to cover seams, protect walls from damage, and add a touch of elegance to any space.Aluminum Wall Trim finds its application in a wide range of scenarios, from enhancing the appearance of walls in offices and retail spaces to providing a protective barrier in high-traffic areas such as hospitals and schools. It is also commonly used in home renovations, where it can be installed around windows, doors, and along baseboards to create a seamless and polished look. This product is particularly popular in contemporary designs, where its metallic finish complements various color schemes and architectural styles.

Okorder.com is a reputable wholesale supplier of Aluminum Wall Trim, boasting a large inventory that caters to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Aluminum Wall Trim product meets the highest industry standards. Their extensive range of styles, sizes, and finishes allows customers to find the perfect trim to suit their specific project requirements, making Okorder.com the go-to destination for all Aluminum Wall Trim needs.

Hot Products