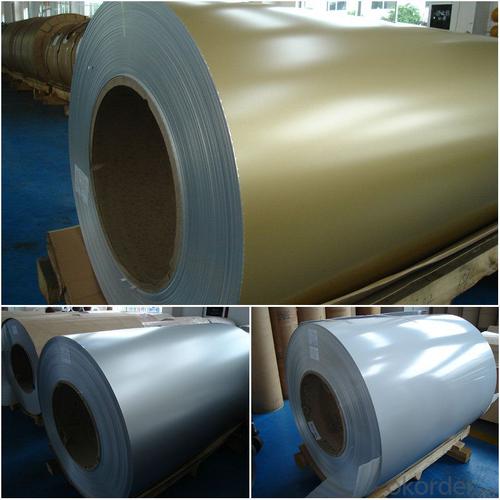

Aluminum Coil Price Per Pound - Color Prepainted Aluminum Panel Sheet 3105h44

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color coated aluminum magnesium alloy Al-Mn

First, the raw materials:

Al-Mn-Mg aluminum alloy is in generalbased on the addition of manganese and magnesium components, and its productsthan the average tensile strength and elongation strength aluminum, doubled,and its corrosion resistance to oxidation has been further enhanced in Metalindustry is known as rust aluminum. Therefore, Al-Mn-Mg alloy 3004 with arust-proof characteristics and high strength, wide range of uses.

Second,the Al-Mn-Mg alloys the characteristics of color coated aluminum

Colorcoated aluminum magnesium alloy Al-Mn alloy is used for the 3004 state of theAl-Mn-Mg aluminum alloy substrate, after de-ester, cleaning, passivation layerprocessing, and then painting on this basis, the international most advancedlevel of KANAR500 and HYLAR5000 Series Fluorocarbon (PVDF) resin coating, thecolor coated aluminum manganese alloy known international companies use theU.S. PPG, Sweden and the United States Weishi Bo Beca companies paint company,its products by the natural light exposure, Florida testing, with more than 20years of weathering quality assurance. Color coated aluminum magnesium alloyAl-Mn advantages of raw materials, its products have a high strength, corrosionresistance, high weather resistance and other characteristics, and according totheir own customers were asked to choose a different color palette, you cancolor integration, can co-exist to gorgeous effect.

Third,Al-Mn-Mg alloys the use of color coated aluminum

Ourcompany specializes in aluminum color coated aluminum manganese alloy has beenwidely used in large factories, exhibition halls, stadiums, airports, trainstation roof and ceiling decorative envelope system board. Thickness of thealuminum can choose different color coated aluminum magnesium alloy ofmanganese, by cutting, pressing, punching, bending and other follow-up moldingprocess for large span, the larger the overall roof, wall decorative panelsused in construction; You can also cut into small panels by bending, stampingmold, etc., for indoor decorative roof plate; also with polyurethane foam,bonded aluminum honeycomb composite construction for energy-saving decorativewall plates.

Fourth,the development prospects

As the field of building decoration materials, the continuous improvementrequirements, as poor performance of color coated steel corrosion, rust, yellowrust after a large amount of the deficiency of serious impact on the building'soverall appearance, the urgent need to develop a color plate with bothstrength, but also overcome the shortcomings of color-coated steel, while thereare long-term durability of new materials, building decoration, used inairports, commercial buildings, train stations, subways, hospitals and otherarchitectural decoration. The Al-Mn-color coated aluminum magnesium alloymaterials precisely meet these requirements, with the expanding domesticdemand, strengthen public infrastructure under the principle of color coatedaluminum magnesium alloy of manganese will become an increasingly widespreaduse of aluminum, a good prospect.

Embossed color coatedaluminum coil

the company can produce the aluminum coil pattern are: classic orange peel pattern,and variation orange peel pattern (also called as bugs’ pattern). Thicknessspecification is 0.2mm ~ 0.6mm, width less than 1600mm. The materials used arefluorocarbon coated aluminum, polyester coated aluminum coil, aluminum roll,light aluminum, brushed aluminum rolls.

By embossing the surface of aluminum coil elegant, streamlined good, solidsense. Embossed aluminum coil aluminum coil can not only increase the thicknessof the aluminum coil thickness of 0.1 ~ 0.25mm. At the same time can enhance thestrength of aluminum coil, stiffness, and does not affect the original surfacelayer of the aluminum coil with the performance.

Embossed aluminum coil, wide range of uses. Mainly used for indoor and outdoordecoration, freezer, refrigerator, decorative aluminum products, bags, centralair conditioning and ventilation nozzles, and mechanical equipment enclosuresand so on. Is a new decorative material.

Thecompany has two production lines embossed aluminum coil: one for the simpleformula: put through Unwinder mechanical embossing roll winder windingembossed, convenient and quick. Another is the compound: that is embosseddirectly into the device placed in the coating line, coating and embossingsynchronization, when the coating needs of embossed aluminum coil, through thehydraulic transmission, the embossing machine, under the pressure rollerengagement, aluminum coating line directly in the embossing roll, fast, lowcost, no turnover.

Thickness range

0.2mm—0.6mm

Width range

800mm—1590mm

Technical parameters

Aluminum thickness | Coating thickness | MEK | T-bend | Impact | Adhesion | Pencil hardness | Boiling water proof |

0.20-0.60mm | ≥18±1um | ≥100times | ≤3T | 50kg.cm | 0grade | ≥HB | no change within 2 hours |

Performance and Application

Embossed aluminum coil for roofing is coatedwith high-performance polyester paints. And its each performance index is up toor exceeds the national standard. With its glorious colors, little chromatism,strong impact and easy machinability, the product serves as a premium materialin roofing, electric appliances, etc.

Export sea worthy packing,coilOD and through coil ID covered with water proof polythene film to avoidcondensation and white rusting,over the polythene film the coils covered withhard cardboard.Coils should be place on wooden pallets.Coils ID contain hardinner cardboard sleeve.

Used for manufacture decorative materials, such as aluminum veneers, ACP aluminum composite panels, honeycomb panels, aluminum roofing, lighting decoration, household electrical appliances, food package(such as pop can cover and ring-pull),and furniture etc.:

1) Exterior applications: wall cladding, facades, roofs and canopies, tunnels, column covers or renovations;

2) Interior applications: wall cladding, ceilings, bathrooms, kitchens and balconies;

3) Advertisement and market applications: display platforms, signboards, fascias and shop fronts;

4) Transport and industrial applications

- Q: Can aluminum coils be used in automotive radiators?

- Certainly, automotive radiators can make use of aluminum coils. As a matter of fact, aluminum is extensively employed in radiator production owing to its exceptional heat transfer characteristics and lightweight attributes. The efficiency of aluminum coils in heat dissipation makes them highly favored for automotive purposes. Moreover, aluminum resists corrosion, an imperative feature for a component that interacts with coolant. By employing aluminum coils in automotive radiators, the cooling system's overall effectiveness and performance are enhanced while reducing the radiator's weight. Ultimately, this contributes to improved fuel economy and overall vehicle performance.

- Q: Its got probably 330 horses right now with aluminum heads what do you think it be approx.

- Head material does NOTHING. It is the DESIGN of the heads that is important. WHAT kind of car is this??Aluminum heads can crack easier depending upon WHO makes the heads and for what application. Expect NO real improvement. There are OTHER considerations, like intake system. cam shoice, compression ratio, and other factor5s. GOOD LUCK!!

- Q: This question asks whether aluminum coils are produced using recycled materials.

- <p>Yes, aluminum coils can be made from recycled materials. Recycling aluminum is a common practice because it conserves resources and energy. Recycled aluminum, also known as secondary aluminum, is processed from various waste materials such as used beverage cans, automotive parts, and construction materials. The recycling process involves melting the scrap aluminum, which requires significantly less energy compared to producing aluminum from raw materials. This makes the production of aluminum coils from recycled materials more sustainable and environmentally friendly.</p>

- Q: How are aluminum coils used in the production of industrial machinery?

- Aluminum coils are commonly used in the production of industrial machinery for various purposes. These coils are primarily utilized in the fabrication of heat exchangers, such as condensers and evaporators, due to aluminum's excellent thermal conductivity. Additionally, aluminum coils are used to manufacture air conditioning systems, refrigeration units, and cooling towers, as they offer lightweight and corrosion-resistant properties. They are also employed in the construction of electrical transformers and motors due to their high electrical conductivity. Overall, aluminum coils play a crucial role in the manufacturing of industrial machinery, contributing to enhanced efficiency, durability, and performance.

- Q: Is it possible to join steel coils using arc welding or gas welding techniques?

- <p>Yes, steel coils can be welded together using both arc welding and gas welding methods. Arc welding, specifically processes like Shielded Metal Arc Welding (SMAW) and Gas Metal Arc Welding (GMAW), is commonly used for joining steel due to its strength and versatility. Gas welding, which uses a fuel gas and an oxygen mixture to produce a flame, is also suitable for steel welding, although it may be less common in industrial settings due to the higher heat input and potential for distortion. Proper techniques and equipment are essential to ensure a strong, durable weld and to avoid defects such as cracking or warping.</p>

- Q: Are aluminum coils suitable for pharmaceutical vial caps?

- Pharmaceutical vial caps can indeed be made from aluminum coils. When it comes to pharmaceutical packaging, aluminum is highly favored thanks to its exceptional barrier properties. These properties effectively shield the vials' contents from moisture, oxygen, and other harmful substances. Aluminum coils can be easily molded into caps of various sizes and shapes, accommodating different types of vials. Another advantage is that aluminum is a lightweight material, which makes transportation and handling hassle-free. Additionally, aluminum is resistant to corrosion, ensuring that the vial caps remain intact throughout storage and usage. In summary, due to their barrier properties, versatility, and durability, aluminum coils are a suitable option for pharmaceutical vial caps.

- Q: Are there any limitations to the maximum coil length of aluminum coils?

- The maximum length of aluminum coils is subject to certain limitations. Factors that affect the maximum coil length include the thickness and width of the coil, the strength and tensile properties of the aluminum alloy, the equipment used for coil processing, and the intended application of the coil. One limitation is the strength and ductility of the aluminum alloy. Aluminum alloys with higher strength and lower ductility may have restrictions on the maximum coil length due to the risk of coil breakage or deformation during processing or handling. Another limitation is the coil processing equipment. The maximum coil length is often determined by the size and capabilities of the equipment used for slitting, cutting, or forming the coils. If the equipment has limited capacity or is not designed for longer coils, it may not be able to effectively handle or process longer lengths. The intended application of the coil can also impose limitations. For example, in the automotive industry, there may be restrictions on the maximum coil length based on the size and weight limitations of the vehicles. Moreover, logistical factors such as transportation and storage can also impose limitations. Longer coils may be more challenging to handle, transport, and store, which can increase the risk of damage or pose challenges in terms of logistics and space requirements. Therefore, it is crucial to consider various factors such as alloy properties, equipment capabilities, application requirements, and logistical considerations to determine the practical limitations of coil length for a specific situation, as there is no specific universal limit to the maximum coil length of aluminum coils.

- Q: How is Aluminum formed??Thanks!!

- okorder nice.

- Q: What are the different alloys used in aluminum coils?

- Some of the different alloys used in aluminum coils include 1100, 3003, 5052, and 6061.

- Q: Are there any safety concerns when handling aluminum coils?

- Yes, there are safety concerns when handling aluminum coils. Aluminum coils can be sharp and may cause cuts or injuries if mishandled. Additionally, aluminum coils may contain sharp edges or burrs which can pose a risk of injury. It is important to handle them with proper protective equipment such as gloves and ensure safe lifting techniques to avoid any accidents.

Send your message to us

Aluminum Coil Price Per Pound - Color Prepainted Aluminum Panel Sheet 3105h44

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords