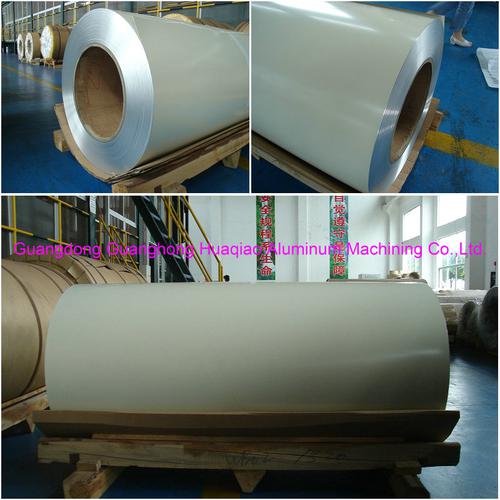

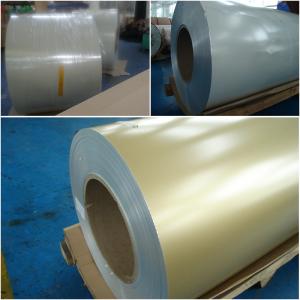

Aluminum Coil Stock - PE Prepainted Aluminum Coil Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PE彩涂铝卷产品是采用聚酯涂料经专业辊涂烘烤加工而成。色泽靓丽,颜色多样,选择方便;色差小,耐冲击、易加工,各项性能均达到或超过国家相关标准。产品广泛用于室内及门面装修,天花扣板、屋面瓦、墙板、广告招牌、柜台、家电家具、车体游船等内外装饰。

技术参数

铝材厚度 | 涂干膜厚度 | MEK | T弯 | 冲击 | 附着力 | 铅笔硬度 | 耐沸水 |

>0.3mm | ≥18±1um | ≥100次 | ≤3T | 50kg.cm | 0级 | ≥HB | 2h无变化 |

0.2~0.3mm | ≥18±1um | ≥100次 | ≤3T | 20kg.cm | 0级 | ≥HB | 2h无变化 |

0.15~0.18mm | ≥15±1um | ≥80次 | ≤4T | 20kg.cm | ≤1级 | ≥HB | 1h无变化 |

0.08~0.12mm | ≥15±1um | ≥80次 | ≤4T | 10kg.cm | ≤1级 | ≥HB | 1h无变化 |

0.026~0.06mm | ≥12±1um | ≥50次 |

| 10kg.cm | ≤1级 | ≥HB | 1h无变化 |

PE Aluminum Coating Coils for ACP

Features of PE Aluminum Sheet:

1. Adopting precision rolling coatingtechnology, our PVDF and PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PE coated aluminum coil weproduced, there are various colors for your choice.

3. Using infrared heating technology toprotect environment from pollution.

4. Our coated aluminum coil has four-rollercoating line, uniform coating thickness and good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wall panels, advertisement boards, counters,home appliances, decoration in and out of autos and boats.

Performance of the coating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: Is it possible to use a magnet to determine if an aluminum coil has magnetic properties?

- <p>No, you cannot use a magnet to test the magnetic properties of an aluminum coil. Aluminum is a non-magnetic material, meaning it does not have magnetic properties and will not be attracted to a magnet. Magnets are used to test ferromagnetic materials like iron, nickel, and cobalt. To test for magnetic properties, you would need to use a different method, such as an electromagnetic induction test, which can detect magnetic fields generated by electrical currents in a coil.</p>

- Q: What are the production processes of aluminum coil and what are the functions of various industrial furnaces in the production of aluminum? The more detailed, the better. Thank you! Points!

- General steps are as follows: melting - hot rolling - cold rolling - annealing – shearing – straightening – punching

- Q: Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers durability, lightweight properties, and resistance to corrosion. It can be easily shaped, painted, or coated to match various design aesthetics. Additionally, aluminum coils are commonly used for decorative purposes like ceiling panels, wall cladding, and furniture components, making them a popular choice in interior design projects.

- Q: Is it possible to use a soldering iron to fix a damaged or broken aluminum coil?

- <p>Using a soldering iron to repair an aluminum coil is not typically effective. Aluminum has a high thermal conductivity and doesn't bond well with solder, making it difficult to create a strong joint. Instead, consider using specialized aluminum welding techniques or brazing, which involves using a filler metal with a melting point higher than the base metal. For small repairs, you might also explore the use of aluminum repair epoxy or other adhesives designed for metal bonding. Always ensure to follow safety precautions and consult with a professional if the repair is complex or if the coil is part of a critical system.</p>

- Q: What are the potential applications of stucco-embossed aluminum coils?

- Stucco-embossed aluminum coils have a wide range of potential applications due to their unique properties and aesthetic appeal. Here are some potential applications of stucco-embossed aluminum coils: 1. Building and construction: Stucco-embossed aluminum coils are commonly used in the construction industry for cladding and roofing purposes. The textured surface of the stucco pattern enhances the durability and strength of the aluminum, making it suitable for exterior applications. It can be used on commercial and residential buildings to provide a visually appealing and long-lasting finish. 2. Insulation: Stucco-embossed aluminum coils can also be used for insulation purposes. The textured surface helps to increase the surface area, which improves the thermal conductivity of the material. This makes it an ideal choice for applications where heat transfer needs to be controlled, such as in HVAC systems or refrigeration units. 3. Appliances: Stucco-embossed aluminum coils are commonly used in the manufacturing of various appliances. The textured surface not only adds visual interest but also provides a durable and easy-to-clean finish. It can be used for the production of kitchen appliances like refrigerators, dishwashers, and ovens, as well as for other household appliances such as air conditioners or water heaters. 4. Transportation: Stucco-embossed aluminum coils find applications in the transportation industry as well. The textured surface provides improved traction, making it suitable for flooring and decking in vehicles like buses, trains, and ships. It is also used for decorative purposes in the interior and exterior parts of automobiles, giving them a stylish and modern look. 5. Packaging: Stucco-embossed aluminum coils can be utilized in the packaging industry as well. The textured surface adds strength and rigidity to the material, making it ideal for manufacturing containers, trays, and packaging materials that require durability and protection. It can be used for food and beverage packaging, pharmaceutical packaging, and various other applications where a strong and visually appealing packaging solution is needed. Overall, the potential applications of stucco-embossed aluminum coils are diverse and versatile. From construction to insulation, appliances to transportation, and packaging to various other industries, the unique properties and aesthetic appeal of stucco-embossed aluminum make it a popular choice for a wide range of applications.

- Q: What are the typical mechanical properties of aluminum coils?

- The typical mechanical properties of aluminum coils include high strength, good formability, excellent corrosion resistance, low density, and high thermal conductivity. Additionally, aluminum coils often have good electrical conductivity and are easily machinable.

- Q: What are the common testing methods for aluminum coils?

- There are several common testing methods for aluminum coils that are used to ensure their quality and performance. These methods include: 1. Visual inspection: This involves a thorough examination of the coils for any visible defects such as dents, scratches, or surface irregularities. Visual inspection is a basic and initial step in the testing process. 2. Dimensional measurement: This method involves measuring the dimensions of the aluminum coils to ensure they meet the specified requirements. This includes measuring the length, width, and thickness of the coils. 3. Tensile testing: Tensile testing is performed to assess the mechanical properties of the aluminum coils, such as their strength and elasticity. This test involves applying a tensile force to a sample of the coil until it breaks or deforms, allowing for the determination of its tensile strength. 4. Hardness testing: The hardness of aluminum coils is an important factor in determining their suitability for specific applications. Various hardness testing methods, such as Rockwell or Brinell hardness tests, can be used to measure the resistance of the coil's surface to indentation or scratching. 5. Chemical composition analysis: This method involves analyzing the chemical composition of the aluminum coil to ensure it meets the required specifications. Common techniques used for this analysis include spectroscopy or X-ray fluorescence (XRF) analysis. 6. Corrosion resistance testing: Aluminum coils are often exposed to harsh environmental conditions, so assessing their resistance to corrosion is crucial. This can be done through various tests like salt spray testing or electrochemical impedance spectroscopy (EIS) to determine the coil's ability to withstand corrosion. 7. Coating quality assessment: If the aluminum coil is coated with a protective layer, testing methods such as adhesion testing, coating thickness measurement, or impact resistance testing can be used to ensure the quality and durability of the coating. These are some of the most common testing methods employed for aluminum coils. By conducting these tests, manufacturers can ensure that the coils meet the required standards and perform optimally in their intended applications.

- Q: What are the potential applications of mill-finished aluminum coils?

- Mill-finished aluminum coils have a wide range of potential applications due to their excellent corrosion resistance, lightweight nature, and versatility. Some common applications include roofing, insulation, cladding, automotive parts, electronic casings, and packaging materials. Additionally, mill-finished aluminum coils can be further processed or coated to suit specific needs in industries such as construction, transportation, aerospace, and consumer goods.

- Q: Can aluminum coils be used in food processing applications?

- Food processing applications can utilize aluminum coils, as they offer a range of advantages. Aluminum is a widely used and highly adaptable material in the food industry due to its various benefits. Aluminum coils are lightweight, durable, and possess excellent thermal conductivity, which makes them suitable for applications requiring efficient and uniform heat transfer. When it comes to food processing, aluminum coils are commonly employed in equipment such as heat exchangers, evaporators, and refrigeration units. These coils help to cool, heat, or maintain the temperature of different food products during their processing, storage, or transportation. The exceptional thermal conductivity of aluminum ensures that heat is evenly dispersed, thereby aiding in the preservation of food quality and flavor. Furthermore, aluminum is a non-toxic and non-reactive metal, meaning it has no adverse effects on the taste or composition of the processed food. It is also naturally resistant to corrosion, ensuring that the coils do not contaminate the food and can be easily cleaned and maintained. In addition, aluminum is an environmentally friendly and recyclable material, aligning with the increasing demand for sustainable practices in the food industry. Its lightweight nature also contributes to energy efficiency and reduced transportation expenses. In conclusion, aluminum coils are a reliable, efficient, and safe choice for food processing applications. They meet the strict requirements of the industry while ensuring the quality and safety of the processed food.

- Q: What are the weight savings achieved by using aluminum coils?

- The weight savings achieved by using aluminum coils can vary depending on the specific application, but generally speaking, aluminum coils are significantly lighter than traditional materials such as steel. On average, aluminum coils can provide weight savings of around 50% or more compared to steel coils. This weight reduction is especially beneficial in industries like automotive, aerospace, and construction, where lighter materials can contribute to improved fuel efficiency, increased load capacity, and enhanced overall performance.

Send your message to us

Aluminum Coil Stock - PE Prepainted Aluminum Coil Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords