Adp Aluminum Coil Cx360b635 - Color Coated Aluminum Coil CNBM Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product Introduction

Color Coated Aluminum Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification:

Name | Color Coated Aluminum Coil | |

Brand | CMAX | |

Alloy | 1100,1235,3003,3004,3005,3105,5005,5052,8011 | |

Thickness | 0.2mm~200mm | |

Width | 40mm -1500mm | |

MOQ | 5T | |

Coating finish | PVDF,POLYESTER,NANO,BRUSHED | |

Color | As to code RAL | |

Surface | Embossed,Mill Finish,Coated | |

Gloss | 10-90%(EN ISO-2813:1994) | |

Total coating thick | PVDF 25 micron | |

Polyester 18micron(EN ISO-2360:1995) | ||

Coating hardness | 2H | |

Adhesion | 5B (EN ISO-2409:1994) | |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) | |

Flexibility (T-bend) | 0T- 2T | |

MEK resistance | 100 | |

Certification | ISO9001,SGS | |

Usuage | Exterior applications | wall cladding, facades, roofs and canopies, tunnels, |

Interior applications | wall cladding, ceilings, bathrooms, kitchens and | |

Advertisement and market applications | display platforms, signboards,fascias and shop fronts | |

Coil's standard diameter | 1100mm | |

Coil's standard weight | 2000kgs | |

Botton side aluminium sheet is coated with protective polyester material,thickness more than 6 micron | ||

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

l CNBM World Wide

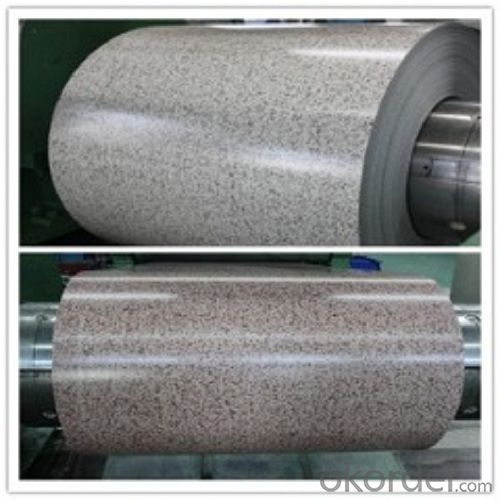

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email: service@okorder.com

- Q: Tossing away an aluminum can wastes as much energy as pouring out half of that can’s volume of gasoline.what does that mean?

- Aluminum cans are made of energy so there is as much energy in the can as in half a can of gasoline.

- Q: I have a muffin pan made of aluminum foil and I do not know if i can put it in the oven to cook some muffins. Many sights say it will melt but they say that about putting a sheet of foil at the bottom of the oven for a long time. I just want it to be in their for half an hour to make muffins.

- Aluminum Foil In Oven

- Q: What are the safety considerations when handling aluminum coils?

- When working with aluminum coils, it is crucial to take several safety factors into consideration. To begin with, it is essential to understand that aluminum coils can be quite heavy, particularly when dealing with larger sizes. Therefore, it is important to employ correct lifting techniques to prevent strain or injury to the back and muscles. This may involve using lifting aids or seeking assistance from others when moving or positioning the coils. Furthermore, aluminum coils may have sharp edges or corners that can cause cuts or puncture wounds if not handled with care. It is advisable to wear suitable personal protective equipment, such as gloves, to protect against potential injuries while handling the coils. In addition, aluminum is an excellent conductor of both electricity and heat. Consequently, it is of utmost importance to ensure that the coils do not come into contact with live electrical sources or come into close proximity to open flames or intense heat. This precautionary measure can help prevent electrical shocks or fires, which present significant safety risks. Moreover, proper storage and stacking of aluminum coils play a crucial role in accident prevention. Coils should be stored in a stable and secure manner to avoid the risk of falling or rolling over. Employing appropriate stacking techniques, such as using suitable supports or pallets, is essential to prevent toppling. Finally, it is imperative to be familiar with any specific safety guidelines or regulations provided by the manufacturer or relevant authorities when working with aluminum coils. Adhering to these guidelines ensures the safe handling and use of the coils, minimizing the risk of accidents or injuries. To summarize, the safety considerations when handling aluminum coils involve employing correct lifting techniques, wearing personal protective equipment, avoiding contact with electrical sources and heat, ensuring proper storage and stacking, and following manufacturer guidelines. Implementing these precautions significantly reduces the risk of accidents or injuries.

- Q: What are the best rust-proof coils? Please tell me the model and manufacturer in Shangdong. Thank you.

- 3003 aluminum coil, AL-Mn series alloy, is the most widely used rust-proof aluminum with the density being 2.73. It is applicable to insulation projects such as pipe insulation, packaging, machine parts, refrigerator, air conditioning and ventilation pipes and other wet environment.

- Q: How are aluminum coils used in the production of architectural panels?

- Aluminum coils are used in the production of architectural panels as they serve as the primary material for manufacturing these panels. The coils are processed through various techniques such as cutting, bending, and shaping to create the desired shape and dimensions for the architectural panels. These panels are then used for cladding, roofing, or wall systems in buildings, providing aesthetic appeal, weather protection, and structural integrity.

- Q: Why the end of the aluminum coil will have a yellow spot?

- The reason may be that the manufacturer is not cleaned, and must be carefully cleaned before coating, or there may be paint fall off phenomenon.

- Q: What are the different tempers available for aluminum coils?

- There are several different tempers available for aluminum coils, each offering unique characteristics and properties. The most common tempers include: 1. O Temper: Also known as annealed or soft temper, this is the softest and most ductile temper available. It is characterized by low strength and high formability, making it suitable for applications that require extensive forming or bending. 2. H Temper: The H temper series includes various levels of work hardening, resulting in increased strength and reduced formability compared to the O temper. The H temper range includes H1X, H2X, H3X, H4X, H5X, and H6X, with each subsequent number indicating a higher level of work hardening. These tempers are commonly used in applications that require moderate to high strength. 3. T Temper: The T temper series, also known as heat-treated tempers, involves thermal treatments to achieve a specific combination of strength and formability. The most common T tempers include T3, T4, T6, and T7. T3 and T4 are solution heat-treated and naturally aged, providing a good balance of strength and formability. T6 and T7 are solution heat-treated and artificially aged, resulting in higher strength but reduced formability. 4. F Temper: The F temper, also known as as-fabricated temper, is obtained by hot working or cold working the material without subsequent thermal treatments. It offers improved strength and hardness compared to the O temper but lower than the H and T tempers. These different tempers allow aluminum coils to be used in a wide range of applications, from automotive parts and aerospace components to building materials and consumer goods. The choice of temper depends on the specific requirements of the application, including desired strength, formability, and corrosion resistance.

- Q: Are aluminum coils suitable for high-reflective applications?

- Yes, aluminum coils are highly suitable for high-reflective applications. Aluminum has excellent reflective properties, making it ideal for a wide range of applications requiring high reflectivity, such as solar panels, LED lighting, and reflective coatings. Additionally, aluminum is lightweight, durable, and corrosion-resistant, making it a preferred choice for various industries.

- Q: I need to make aluminum powder. What machine should I use and what aluminum object should I use?

- The okorder

- Q: Are aluminum coils more cost-effective compared to other materials like copper?

- Aluminum coils are generally more cost-effective than other materials like copper for several reasons. To begin with, aluminum is a more abundant metal, making it cheaper to produce. Its abundance also results in more stable prices, reducing the likelihood of market fluctuations and further enhancing its cost-effectiveness. Furthermore, aluminum coils have a lower density compared to copper coils, resulting in lighter units. This lighter weight not only reduces costs for transportation and installation but also makes them easier to handle and maneuver during the manufacturing process. In addition, aluminum coils possess excellent thermal conductivity properties, enabling efficient heat transfer. This leads to more efficient cooling or heating systems, resulting in lower energy consumption and operating costs in the long run. Moreover, aluminum exhibits higher resistance to corrosion compared to copper, making it more durable and requiring less maintenance. The longer lifespan of aluminum coils reduces the need for replacements and repairs, further contributing to their cost-effectiveness. Lastly, aluminum coils are recyclable, and the recycling process requires significantly less energy than producing new aluminum. This aspect adds to the overall sustainability and cost-effectiveness of aluminum coils. In conclusion, considering their lower production costs, lighter weight, superior thermal conductivity, increased durability, and recyclability, aluminum coils are indeed a more cost-effective option compared to materials like copper.

Send your message to us

Adp Aluminum Coil Cx360b635 - Color Coated Aluminum Coil CNBM Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords