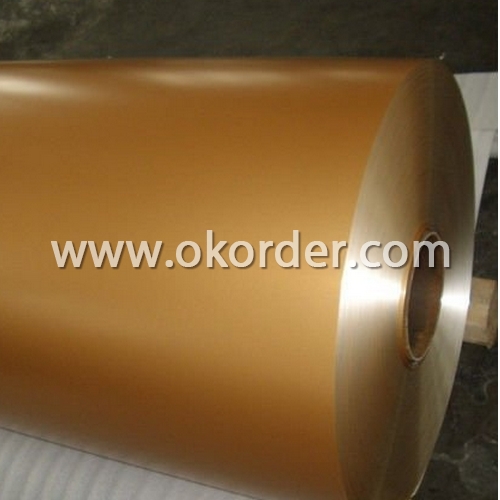

1050 Aluminum Sheet Coil with Anti-Scratch Coating

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.General Information of anti-scratch coated aluminium coil/sheet:

Anti-scratch Coated aluminum coil is between 0.10 mm and 4.00mm in thickness with PVDF, PE. Color is according to RAL colors or customer's sample. The coated aluminum coil/sheet has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

2.Features of anti-scratch coated aluminium coil/sheet:

CNBM produces aluminum coils which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

3.The main producing procedure of anti-scratch coated aluminium coil/sheet:

Rolling--Annealing--Slitting—Rinsing—Coating—Baking---Coiling

4. Specification of anti-scratch coated aluminium coil/sheet

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-4.0mm |

Width: | 10mm- 2200mm |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

coated aluminium, coated aluminiumcoil,pvdf coated aluminium panel,pe coated aluminium sheet,composite aluminium panel,roller coating aluminium sheet,

Alloy:1050/1060/1070/1100/1200/3003/3004/3104/5052/5754/5083/8011. Temper:O/H12/H14/H16/H18/H19/H22/H24/H26. Thickness:0.006-8mm. pvdf roller coating/coated aluminium coil/sheet can suit for large area house and wall decoration when finished by cut and punch further processing. Rolling coating coil for ceiling and roofing includes PVDF series/nanometer series/pearly luster series/self clean series/anti scratch series and wood grain series for different ceiling/roofing/house decorative and lamp decoration.

taking samples from the real wood and marble stone and with supreme coating technology,our wood/marble rolling will show you elegant,tridimensional and clear texture,be of easy clean,weather resistance,environment friendly high strength,which the real wood and marble can not reach. The wood/marble coils are especially suitable for project,house and indoor high pressure decoration.

- Q: Is it safe and practical to utilize aluminum coils for food storage purposes?

- <p>Aluminum coils can be used for storing food, but it's important to consider the type of food and the conditions. Aluminum is a good conductor of heat, making it suitable for cooking and preserving food in certain contexts, such as in foil form for wrapping food for baking or grilling. However, for long-term storage, especially of acidic or alkaline foods, aluminum may not be ideal due to potential leaching of aluminum into the food, which could be harmful. It's also crucial to ensure that the aluminum is food-grade and not contaminated with harmful substances. For most food storage needs, other materials like glass, stainless steel, or food-grade plastic are often preferred due to their non-reactive nature and safety.</p>

- Q: What unique considerations or precautions need to be taken when handling aluminum coils?

- <p>When handling aluminum coils, there are several special requirements to consider. First, it's crucial to handle the coils carefully to avoid denting or scratching the surface, which can affect their quality and value. Secondly, due to aluminum's lightweight and high strength, specialized equipment like slitters and rewinders may be necessary to process the coils. Additionally, it's important to store aluminum coils in a dry environment to prevent corrosion. Proper ventilation is also required to avoid condensation, which can lead to oxidation. Finally, safety measures such as wearing protective gear and following material handling guidelines are essential to prevent accidents and injuries.</p>

- Q: What are the different protective coatings available for aluminum coils?

- There are several different protective coatings available for aluminum coils. Some common options include: 1. Polyester Coating: This is a versatile coating that provides excellent weather resistance and color retention. It is commonly used in outdoor applications where the aluminum coils may be exposed to harsh weather conditions. 2. Polyvinylidene Fluoride (PVDF) Coating: PVDF coatings are known for their exceptional durability and resistance to fading, chalking, and chemical exposure. They are often used in architectural applications where a long-lasting and high-performance finish is required. 3. Epoxy Coating: Epoxy coatings offer excellent adhesion and corrosion resistance. They are frequently used in industrial settings, such as in the manufacturing of appliances or automotive parts. 4. Acrylic Coating: Acrylic coatings provide good weatherability and UV resistance. They are commonly used in interior applications or in environments with mild outdoor exposure. 5. Polyurethane Coating: Polyurethane coatings offer a high level of impact resistance and flexibility. They are often used in applications where the aluminum coils may be subject to physical stress or deformation. 6. Ceramic Coating: Ceramic coatings provide superior heat resistance and thermal stability. They are commonly used in automotive applications or in environments with high-temperature exposure. Overall, the choice of protective coating for aluminum coils depends on the specific application requirements, such as weather resistance, durability, or chemical resistance. It is important to consider the environmental conditions and performance expectations when selecting the appropriate coating for aluminum coils.

- Q: Is it safe and effective to use an oven to heat an aluminum coil?

- <p>Yes, you can use an oven to heat an aluminum coil, but with caution. Aluminum has a high melting point and can withstand high temperatures, making it suitable for heating in an oven. However, it's crucial to ensure that the coil is clean and free of any non-stick coatings or residues that could produce toxic fumes when heated. Additionally, monitor the temperature and duration of heating to avoid overheating, which might cause the coil to warp or degrade. Always follow safety guidelines and manufacturer's instructions for your specific oven and aluminum coil.</p>

- Q: What are the different tensile strengths of aluminum coils?

- The tensile strengths of aluminum coils can vary depending on the specific alloy and manufacturing process. However, common tensile strengths for aluminum coils range from 20,000 to 70,000 pounds per square inch (psi).

- Q: How are aluminum coils formed into different shapes and profiles?

- Aluminum coils are formed into different shapes and profiles through a process known as aluminum coil slitting and forming. This involves passing the coil through a series of rollers and dies that apply pressure and force to shape the metal into the desired form. The specific shape and profile are determined by the design of the rollers and dies used in the process.

- Q: Can aluminum coils be used for seamless gutters?

- Yes, aluminum coils can be used for seamless gutters. Aluminum is a popular choice for gutter systems due to its durability, lightweight nature, and resistance to corrosion. Aluminum coils are commonly used to create seamless gutters, which offer several advantages over traditional sectional gutters. Seamless gutters are custom-made on-site, ensuring a perfect fit for the specific dimensions of the building. This eliminates the need for seams, which can be prone to leaks and require regular maintenance. Additionally, aluminum is easy to work with, allowing for seamless gutters to be formed into various shapes to accommodate the unique design of a building. Overall, aluminum coils are a practical and efficient option for creating seamless gutters.

- Q: Can aluminum coils be used in automotive applications?

- Yes, aluminum coils can be used in automotive applications. Aluminum coils are lightweight, which makes them an excellent choice for automotive manufacturers as it helps to reduce the overall weight of the vehicle. This, in turn, can improve fuel efficiency and performance. Additionally, aluminum coils have excellent heat conductivity, which is crucial in automotive applications where heat dissipation is important. Moreover, aluminum coils have good corrosion resistance, which is particularly beneficial in automotive applications where vehicles are exposed to various weather conditions and road salts. Overall, the use of aluminum coils in automotive applications can provide several advantages such as weight reduction, improved fuel efficiency, better heat dissipation, and enhanced corrosion resistance.

- Q: What are the typical delivery methods for aluminum coils?

- The typical delivery methods for aluminum coils include shipping via truck or rail, as well as air freight for urgent or long-distance deliveries.

- Q: What is the difference between aluminum plate and aluminum coil?

- A sheet is flat, one by one for storage, one for coil material, one roll for storage, but aluminum coil can be leveled by machine, that is aluminum plate.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

1050 Aluminum Sheet Coil with Anti-Scratch Coating

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords