Aluminum Coil suppliers Wholesale in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

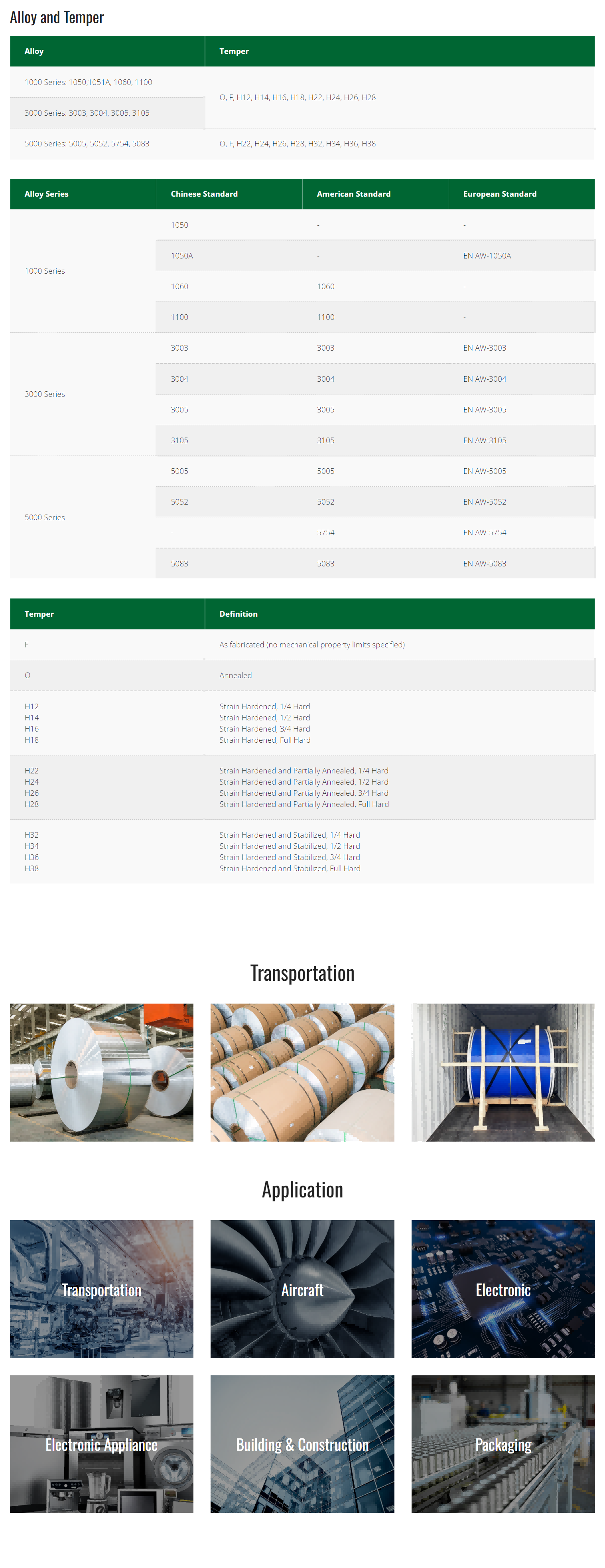

Specification

Aluminum Coil Wholesale in China is designed for many field such as electronics, instruments, lighting decoration, packing industry, and house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc..Aluminum Coil Wholesale in China is hard and everlasting under the blazing sun. You can choose the alloys as your habitation and we will do our best to meet your requests.

Main Features:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

Images:

Images:

FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

2. Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

3. What is the delivery time after purchase?

35 day after receiving client's deposit or correct LC

4.What is Anodized Aluminum and How does the Anode effect impact Electrolysis?

Anodized aluminum refers to aluminum and aluminum alloy plated layer of dense alumina in order to prevent further oxidation, the chemical properties of alumina same. But with the general oxide film is different; it can be stained with anodized aluminum electrolytic coloring.

Anode effect is a phenomenon unique to molten salt electrolysis, and to the performance of aluminum production is still evident. Production of anode effect occurs when the cell voltage rises sharply, reaching 20 ~ 50V, and sometimes even higher. It occurs a significant impact on the entire series of electrolysis, a current efficiency is reduced, the impact of the various technical indicators electrolysis, and so reduces yield and quality aluminum, undermining the smooth supply whole series of electrolysis. In the method of treatment, no more than two ways: with effect rod (stick) extinguish or reduce the anode, increasing the quantity of alumina, in order to achieve the purpose of extinguishing the anode effect. It has yet to find a better approach.

- Q: i used hf acid to clean the rails on my trailer and it left black streaks on the alluminum... uld it be the type of aluminum alloy???

- I have a charcoal grill with diamond plate alluminum . how can i get it to shine again? I used my steam mop and rag it got most but not all?

- Q: How does aluminum ingot be processed to aluminum coil (aluminum sheet)?

- First it should be made into blank and then put on the rolling mill.

- Q: What are the tensile strength properties of aluminum coils?

- The tensile strength properties of aluminum coils can vary depending on the specific alloy and temper of the aluminum. Generally, aluminum has a good tensile strength, ranging from 70 to 700 MPa (megapascals). The specific tensile strength of aluminum coils can be determined through material testing and analysis.

- Q: Can aluminum coils be used for architectural facades?

- Indeed, architectural facades can make use of aluminum coils. The lightweight, durable, and versatile nature of aluminum makes it a favored option for such purposes. With the ability to mold aluminum coils into diverse shapes and sizes, one can create unique and visually pleasing facades. Furthermore, aluminum demonstrates resistance to corrosion, rendering it suitable for outdoor use. Moreover, aluminum allows for easy coating or finishing, enabling an improved aesthetic appeal and protection against environmental factors. All in all, aluminum coils offer an economically viable and environmentally friendly alternative for architectural facades.

- Q: Can aluminum coils be used in the production of aluminum composite windows?

- Yes, aluminum coils can be used in the production of aluminum composite windows. Aluminum coils are commonly used in the manufacturing process of aluminum composite windows. These coils are made from high-quality aluminum and are often used as the raw material that is then formed and shaped into the desired window frames and components. Aluminum coils offer several advantages in the production of aluminum composite windows, including their lightweight nature, durability, and resistance to corrosion. These qualities make aluminum coils a suitable choice for manufacturers looking to produce high-quality and long-lasting aluminum composite windows.

- Q: What are the different coil coating options for aluminum coils?

- Aluminum coils have several coil coating options available, each with unique benefits and characteristics. 1. Polyester: The most commonly used option for aluminum coils is polyester coil coatings. They are highly durable and resistant to weathering, making them perfect for outdoor use. Polyester coatings also retain color well and come in a wide range of colors and finishes. 2. Polyvinylidene Fluoride (PVDF): PVDF coatings are known for their exceptional performance and durability. They excel in UV resistance, chemical resistance, and extreme weather conditions. PVDF coatings maintain their appearance for a longer time, making them ideal for architectural applications. 3. Polyurethane: Polyurethane coatings offer high resistance to abrasion, chemicals, and corrosion. They adhere well and are flexible, allowing for easy forming and bending of the coated aluminum. Polyurethane coatings are commonly used in industrial applications where durability and protection are vital. 4. Silicone-modified Polyester (SMP): SMP coatings combine the advantages of both polyester and silicone coatings. They resist fading, chalking, and environmental pollutants well. SMP coatings provide good flexibility and adhesion, making them suitable for various applications. 5. Epoxy: Epoxy coatings are known for their excellent adhesion and corrosion resistance. They provide a hard, durable finish that withstands chemicals and abrasion. Epoxy coatings are commonly used in industrial settings with harsh conditions. 6. Plastisol: Plastisol coatings are typically used for textured or decorative finishes. They offer flexibility and impact resistance. Plastisol coatings can be customized with different patterns and textures to enhance the appearance of the coated aluminum. Ultimately, choosing the right coil coating option for aluminum coils depends on specific requirements like desired durability, weather resistance, color retention, and appearance. Consider these factors to select the most suitable coating option for your aluminum coils.

- Q: Can aluminum coils be used in electrical transmission systems?

- Aluminum coils have the ability to be utilized in electrical transmission systems. The utilization of aluminum is prevalent in electrical transmission systems due to its advantageous electrical conductivity, high strength-to-weight ratio, and cost-effectiveness in comparison to other materials like copper. Transformers, motors, generators, and other electrical devices benefit from the application of aluminum coils. Additionally, aluminum coils possess the advantage of being lightweight, simplifying their handling and installation in transmission systems. It is important, however, to take into account that aluminum has lower electrical conductivity than copper, necessitating larger cross-sectional areas to achieve the same electrical performance. To maintain efficiency, reliability, and safety, it is crucial to adhere to proper design and engineering practices when sizing and connecting aluminum coils in electrical transmission systems.

- Q: Are aluminum coils suitable for heat exchanger applications?

- Indeed, heat exchanger applications are well-served by aluminum coils. Being a lightweight and highly conductive material, aluminum proves to be an exceptional selection for heat transfer applications. In heat exchangers, aluminum coils present numerous benefits, including exceptional thermal conductivity, resistance to corrosion, and ease of fabrication. These coils find widespread use in a variety of heat exchanger systems, encompassing air conditioning, refrigeration, and automotive applications. Furthermore, aluminum coils lend themselves easily to the formation of diverse shapes and sizes, thereby allowing for greater design flexibility. In summary, when it comes to heat exchanger applications, aluminum coils offer a dependable and efficient solution.

- Q: Are there any fire safety considerations when using aluminum coils?

- When using aluminum coils, fire safety considerations must be taken into account. This is because aluminum is a highly flammable material, and if not handled and installed correctly, it can present a fire hazard. To minimize the risk of fire, it is crucial to install the aluminum coils in a manner that reduces the chance of fire, such as using appropriate insulation and avoiding direct contact with other flammable substances. Furthermore, regular maintenance and inspections should be conducted to detect any potential problems or signs of overheating that may result in a fire. Adhering to fire safety protocols and guidelines, like having a fire extinguisher nearby and ensuring adequate ventilation, can also assist in mitigating the fire risk associated with aluminum coils.

- Q: Can aluminum coils be used for signage and display applications?

- Yes, aluminum coils can be used for signage and display applications. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion, making it an ideal choice for various signage and display purposes. Its flexibility allows for easy shaping and customization, while its smooth surface provides a perfect canvas for printing graphics and designs. Additionally, aluminum coils can be easily mounted, making them suitable for both indoor and outdoor signage and displays.

Send your message to us

Aluminum Coil suppliers Wholesale in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords