Aluminum Coil Factory Directly Wholesale from China Foshan

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

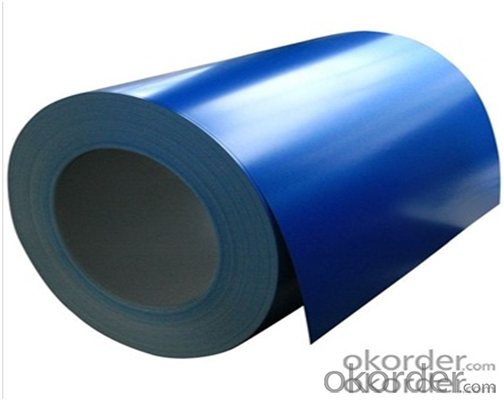

Specification:

Thickness: 0.14mm--1.5mm

Width: 600---1250mm

Zinc coating: Zn60---275g/m2 both side

ID coil: 508mm or 610mm

OD coil: Max 1500mm

Surface Treatment: color coated

Coating structure: 2/1 or 2/2

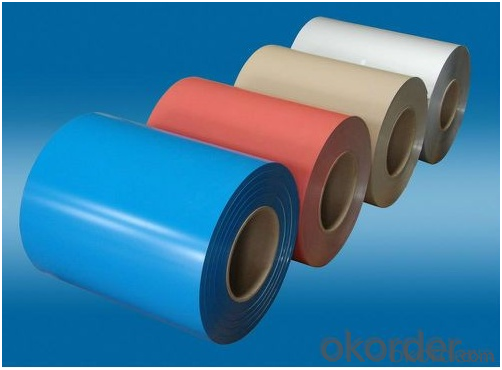

Color: All RAL Colors

Painting thickness: 27-30 microns on top side, 7-9 microns on back Tolerance:+/-0.02mm

Certification: ISO9001

Prepainted Galvanized Coils | Wider Range | Narrow Range | ||

Min. | Max. | Min. | Max. | |

Thickness (mm) | 0.2 | 2.0 | 0.25 | 2.0 |

Width (mm) | 600 | 1250 | 150 | 1000 |

Inside Diameter (mm) | 508 | 610 | 508 | 610 |

Outer Diameter (mm) | 1000 | 2000 | 800 | 1700 |

Prepainted Galvanized Sheets | Wider Range | Narrow Range | ||

Min. | Max. | Min. | Max. | |

Thickness (mm) | - | - | 0.25 | 2.0 |

Width (mm) | - | - | 600 | 1250 |

Length (mm) | - | - | 2000 | 6000 |

Applicating:

general using, Roofing, siding panels, shutters, warehouse and pre-fabricated houses, partitions, doors, home appliances, steel furniture,etc.

Colored coil is high in strength, good in rain and corrosion resistance,widely used in construction industry, such as modern courtyard design, large-sized industrial buildings, prefabricated thermal insulation sandwich board, etc. Along with the development of light industry, transportation and ship building, the application of colored sheet has been expanded form building materials to automobile manufacturing,watercraft interior decoration. Household electrical appliance, furniture, container and cooker, etc., and become a new material substituting to spray coating steel sheet.

Quality:

is a way of life for us and we live by quality in this industry. The quality of our

products and services are widely recognized and we have been maintaining

international quality standards. All the products that we suppliy pass through stringent

quality test before they finally arrive and that gives us a cutting edge over others,

managing in this sphere.

Product Description

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals. Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest.

The earliest citation given in the Oxford English Dictionary for any word used as a name for this element is alumium, which British chemist and inventor Humphry Davy employed in 1808 for the metal he was trying to isolate electrolytically from the mineral alumina. The citation is from the journal Philosophical Transactions of the Royal Society of London: "Had I been so fortunate as to have obtained more certain evidences on this subject, and to have procured the metallic substances I was in search of, I should have proposed for them the names of silicium, alumium, zirconium, and glucium."

Pictures

FAQ

1. What is the applications?

Outdoor decoration, business chain, exhibition of advertisement decoration and display ,ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels etc.

2. What is the popular size?

1000*2000,1200*2400,1219*2438,1220*2440

1000*3000,1250*3000,1500*3000 etc.

3. What is the coating?

Polyester, Fluorocarbon, polyurethane and epoxy coating

4. What is the Surface Quality?

be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

5. How about the shipment?

Shipment: By bulk vessel or By container

Welcome to inquiry us! Hope we can establish a long-term relations of cooperation.

- Q: What happens when you mix Aluminum (or magnesium) with calcium carbonate? Can you write a chemical equation please?

- 2Al + 3CaCO3 = Al2(CO3)3 + 3Ca

- Q: What are the different slitting options for aluminum coils?

- There are several different slitting options available for aluminum coils, depending on the specific requirements and end use of the material. Some of the commonly used slitting options for aluminum coils include: 1. Single Slit: This is the most basic and widely used slitting option, where the aluminum coil is cut into two narrower coils with a single cut along the center. 2. Double Slit: In this option, the aluminum coil is cut into two narrower coils with two parallel cuts along the center, resulting in smaller widths for each coil. 3. Multi-Slit: This option involves cutting the aluminum coil into multiple narrower coils with multiple parallel cuts along the center. It allows for the production of several smaller coils from a single wider coil. 4. Ribbon Slit: This slitting option is used when the aluminum coil needs to be slit into very thin strips, often used in applications such as electrical wiring or packaging. 5. Oscillate Slit: This option is suitable for applications that require varying widths of aluminum strips. The coil is slit in a back-and-forth motion, allowing for flexibility in producing different widths. 6. Custom Slitting: Depending on the specific needs of a project, custom slitting options can be implemented. This involves tailoring the slitting process to achieve unique widths, lengths, or shapes of aluminum strips. It is important to consider the desired application, required dimensions, and the capabilities of the slitting equipment when choosing the appropriate slitting option for aluminum coils.

- Q: How are aluminum coils cleaned and maintained?

- Aluminum coils are commonly used in HVAC systems and refrigeration units, and it is essential to clean and maintain them regularly to ensure optimal performance and efficiency. Here is a step-by-step guide on how to clean and maintain aluminum coils: 1. Safety first: Before starting any cleaning process, ensure that the power to the HVAC system or refrigeration unit is turned off to avoid any accidents. 2. Remove debris: Begin by removing any visible debris, such as leaves, dirt, or dust, from the aluminum coils. Use a soft brush or a vacuum cleaner with a brush attachment to gently remove the debris. 3. Spray cleaning solution: Prepare a cleaning solution by mixing a mild detergent or coil cleaner with water. Follow the instructions on the product label to achieve the correct dilution ratio. Transfer the solution into a spray bottle. 4. Apply the cleaning solution: Spray the cleaning solution onto the aluminum coils, ensuring that all areas are covered. Allow the solution to sit for a few minutes to loosen any dirt or grime. 5. Scrub the coils: Use a soft brush or a coil cleaning brush to scrub the aluminum coils gently. Be cautious not to apply excessive pressure, as it may damage the delicate fins on the coils. Focus on areas with stubborn dirt or buildup. 6. Rinse with water: After scrubbing, rinse the aluminum coils thoroughly with clean water. A hose or a pressure washer on a low setting can be used to ensure all the cleaning solution and dirt are removed. Ensure that the water flows in the opposite direction of the airflow to avoid pushing debris further into the coils. 7. Check for any damage: While cleaning, inspect the aluminum coils for any signs of damage, such as bent fins or leaks. If any issues are found, it is recommended to contact a professional technician for repairs. 8. Allow to dry completely: After rinsing, allow the aluminum coils to air dry completely before turning the power back on. This will prevent any moisture-related issues and ensure the coils are ready for use. 9. Maintain a regular cleaning schedule: To keep the aluminum coils in excellent condition, it is crucial to establish a regular cleaning schedule. Depending on the usage and environmental factors, cleaning every three to six months is generally recommended. However, if the coils are installed in a highly polluted or dusty area, more frequent cleaning may be required. By following these steps and maintaining a regular cleaning schedule, you can ensure that your aluminum coils remain clean, efficient, and in optimal working condition.

- Q: Are aluminum coils suitable for architectural facades?

- Architectural facades can benefit from the use of aluminum coils. This material is favored for its many advantages. Firstly, aluminum's lightweight nature makes it easy to handle and install, especially for complex architectural designs or tall buildings. Secondly, aluminum is highly durable and resistant to corrosion. It naturally resists rust and does not need additional treatments or coatings. This makes aluminum coils suitable for long-term use in various weather conditions, such as coastal areas or harsh climates where corrosion is a concern. Moreover, aluminum coils offer versatility in terms of design and customization. They can be easily shaped into different sizes, profiles, and forms, allowing architects and designers to create unique facades that meet their specific requirements. Aluminum can also be painted or coated in various colors and finishes to achieve the desired aesthetic appeal. In addition to its functional and aesthetic advantages, aluminum is also an environmentally friendly choice. It is a recyclable material, meaning it can be reused endlessly without losing its properties. This makes aluminum coils a sustainable option for architectural facades, aligning with the increasing emphasis on green building practices. Overall, due to their lightweight nature, durability, versatility, and sustainability, aluminum coils are a suitable choice for architectural facades. They offer a wide range of design possibilities while ensuring long-term performance and minimal maintenance requirements.

- Q: What are the common recycling methods for aluminum coils?

- Aluminum coils can be recycled using various methods. Mechanical recycling is a commonly employed technique. It entails shredding the coils into small pieces and then melting them to create new coils. This method is both efficient and cost-effective, as it maintains the quality of the aluminum material while allowing for its reuse. Pyrolysis is another method used for aluminum coil recycling. It involves heating the coils at high temperatures in the absence of oxygen. This process breaks down the aluminum into its constituent elements, enabling the recovery of valuable metals and other byproducts. Chemical recycling is an alternative approach for recycling aluminum coils. It involves dissolving the coils in a chemical solution to separate the aluminum from other materials. The resulting aluminum can then be utilized to manufacture new coils. Lastly, smelting is a method that can be employed for aluminum coil recycling. It revolves around melting the coils and separating impurities through electrolysis. This method facilitates the recovery of pure aluminum, which can be utilized in the production of new coils. In summary, these recycling methods play a pivotal role in reducing the environmental impact of aluminum coil production. They conserve resources, minimize waste, and promote the sustainability of the aluminum industry by encouraging the reuse of materials and decreasing the need for new aluminum production.

- Q: i have about 100lbs of aluminum blocks and scrap.

- WOW.......they must be worth sum money. Lucky you!!!!!!

- Q: I'm having trouble with another chem problemAluminum sulfide reacts w/water to form aluminum hydroxide and hydrogen sulfide. Write the balanced chemical equation for this reaction and find how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide.I already found the balanced equation but I need help on finding how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide. Can someone please explain how it's done?

- No way!! because of the fact inspite of the bat, the helmet and the shin guards the undergo is plenty larger than a human and is going to basically get mad from the bat and kill you. Nope $800,000 isn't something for that!

- Q: Can aluminum coils be used in architectural applications?

- Yes, aluminum coils can be used in architectural applications. Aluminum is a versatile and durable material that is commonly used in the construction industry for its lightweight nature, corrosion resistance, and ease of fabrication. Aluminum coils are often utilized in architectural applications such as roofing, cladding, and facades due to their ability to be easily formed into various shapes and sizes. Additionally, aluminum coils can be coated with different finishes to enhance their aesthetics and provide additional protection against weathering and fading. Overall, aluminum coils are a popular choice for architectural applications as they offer a combination of functionality, aesthetics, and longevity.

- Q: Are aluminum coils suitable for architectural sunshades?

- Yes, aluminum coils are suitable for architectural sunshades. Aluminum is a lightweight and durable material that can withstand various weather conditions. It is also corrosion-resistant, making it ideal for outdoor applications. Additionally, aluminum coils can be easily formed and shaped to create customized designs for sunshades, providing both functionality and aesthetic appeal.

- Q: This is not for around the house. It is for my lab. I am pretty sure these one wires are Aluminum, but I need the connector they were made with and the power cable is copper. Would it be okay to still try to join the two.

- yes but use wire nuts

Send your message to us

Aluminum Coil Factory Directly Wholesale from China Foshan

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords