Aluminum Coil Wholesale from China Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

aluminium coil

good quality

competitive price

short delivery time

long mutual beneficial business cooperation

Detailed informations

1.Alloy:AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011

2.Temper : H12, H14, H16, H18, H22, H24, H26, H32,HO, F

3. Thickness : 0.02mm – 10mm

4. Width : 10mm- 2000mm

5. Standard : ISO9001:2000, SGS , GB/T17748-1999, ASTM, EU standard .

6. Inner diameter : 150mm , 405mm ,500mm 505mm , 508mm

7. Coil weight : 1.5tons – 5.0 tons

8. Surface Quality : be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

9. Shipment: By bulk vessel or By container

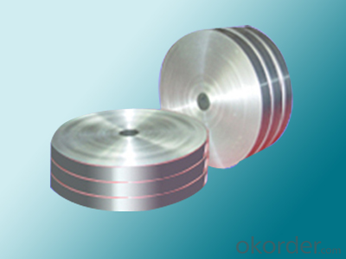

Pictures

Product Description

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals. Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest.

The earliest citation given in the Oxford English Dictionary for any word used as a name for this element is alumium, which British chemist and inventor Humphry Davy employed in 1808 for the metal he was trying to isolate electrolytically from the mineral alumina. The citation is from the journal Philosophical Transactions of the Royal Society of London: "Had I been so fortunate as to have obtained more certain evidences on this subject, and to have procured the metallic substances I was in search of, I should have proposed for them the names of silicium, alumium, zirconium, and glucium."

FAQ

1. What is the applications?

Outdoor decoration, business chain, exhibition of advertisement decoration and display ,ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels etc.

2. What is the popular size?

1000*2000,1200*2400,1219*2438,1220*2440

1000*3000,1250*3000,1500*3000 etc.

3. What is the coating?

Polyester, Fluorocarbon, polyurethane and epoxy coating

4. What is the Surface Quality?

be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

5. How about the shipment?

Shipment: By bulk vessel or By container

Welcome to inquiry us! Hope we can establish a long-term relations of cooperation.

- Q: Can aluminum coils be used in packaging industries?

- Yes, aluminum coils can be used in packaging industries. Aluminum is lightweight, flexible, and has excellent barrier properties that protect the packaged products from moisture, oxygen, and light. It is commonly used for packaging food, beverages, pharmaceuticals, and other consumer goods due to its durability and ability to preserve product quality.

- Q: Is it possible to utilize aluminum coils in the construction industry as building materials?

- <p>Yes, aluminum coils can be used for building materials. They are valued for their lightweight, corrosion resistance, and strength. Aluminum coils are commonly used in roofing, siding, window frames, and facades due to their durability and low maintenance requirements. Additionally, they can be easily shaped and recycled, making them an environmentally friendly option in construction.</p>

- Q: Are aluminum coils suitable for architectural cladding applications?

- Yes, aluminum coils are suitable for architectural cladding applications. Aluminum is a versatile material that offers a range of benefits for cladding purposes. Firstly, aluminum is lightweight, making it easy to handle and install. This reduces the overall weight on the building structure and simplifies the construction process. Additionally, aluminum is highly durable and resistant to corrosion. This makes it an ideal choice for exterior applications, as it can withstand harsh weather conditions and maintain its appearance over time. Furthermore, aluminum coils can be fabricated into various shapes and sizes, allowing for flexibility in design. They can be easily formed, cut, and shaped to meet the specific requirements of the building project. Aluminum is also available in a wide range of finishes and colors, providing architects and designers with ample options to achieve the desired aesthetic for the cladding. Moreover, aluminum is a sustainable choice as it is 100% recyclable. This aligns with the growing focus on environmentally friendly construction practices. Overall, the versatility, durability, lightweight nature, and aesthetic options make aluminum coils a suitable choice for architectural cladding applications.

- Q: How do aluminum coils contribute to sustainable manufacturing practices?

- The numerous environmental and economic benefits of aluminum coils make them crucial for promoting sustainable manufacturing practices. To start, aluminum is an incredibly recyclable material, with almost 75% of all aluminum ever produced still in use today. This means that aluminum coils can be recycled and reused multiple times without losing their quality or performance. Unlike producing new aluminum, recycling aluminum requires only a fraction of the energy, resulting in significant energy savings and reduced greenhouse gas emissions. Furthermore, the lightweight nature of aluminum coils contributes to energy efficiency in transportation and reduces fuel consumption during shipping. This characteristic allows for more efficient use of resources, as less material is needed to achieve the same strength and durability compared to other metals. Consequently, this not only reduces the overall weight of products but also lowers the energy required for their fabrication and transportation. Moreover, the excellent corrosion resistance of aluminum coils extends their lifespan and reduces the need for frequent replacement. This factor not only saves resources but also reduces waste generation and associated environmental impacts. Additionally, aluminum coils are non-toxic and do not release harmful substances into the environment, making them a safe and sustainable choice for various manufacturing applications. In terms of economic benefits, aluminum coils contribute to sustainable manufacturing practices by offering cost savings throughout their lifecycle. The recyclability of aluminum reduces the need for raw material extraction, thereby lowering operational costs and dependence on virgin resources. Additionally, the lightweight nature of aluminum coils allows for more efficient use of energy and resources, resulting in reduced manufacturing and transportation costs. In conclusion, aluminum coils are essential for promoting sustainable manufacturing practices due to their recyclability, lightweight nature, corrosion resistance, non-toxicity, and cost-saving benefits. By integrating aluminum coils into manufacturing processes, companies can reduce their environmental footprint, conserve resources, promote energy efficiency, and contribute to a more sustainable and greener future.

- Q: Can aluminum coils be used in solar thermal systems?

- Yes, aluminum coils can be used in solar thermal systems. Aluminum is a commonly used material for heat transfer in such systems due to its excellent thermal conductivity and corrosion resistance.

- Q: What are the different sizes and dimensions of aluminum coils available?

- The sizes and dimensions of aluminum coils vary depending on the specific industry and application. Generally, aluminum coils are available in a range of widths, thicknesses, and lengths to accommodate various needs. In the construction industry, aluminum coils are commonly available in widths ranging from 24 inches to 60 inches. The thicknesses can range from 0.019 inches to 0.040 inches. The lengths of the coils can vary, but standard lengths are typically around 100 feet or more. For industrial and manufacturing purposes, the sizes and dimensions of aluminum coils can be even more diverse. Coils with widths exceeding 60 inches are available for large-scale applications. The thicknesses can range from 0.006 inches for thin, lightweight coils to 0.250 inches for heavy-duty applications. Additionally, the dimensions of aluminum coils can be customized to meet specific requirements. Some manufacturers offer coil slitting services to cut coils into narrower widths, while others can provide custom lengths or thicknesses based on the customer's specifications. It is important to note that the availability of different sizes and dimensions may vary among suppliers. Therefore, it is advisable to consult with a reputable aluminum coil supplier or manufacturer to determine the specific sizes and dimensions they offer.

- Q: Are there any limitations on the powder coating of aluminum coils?

- Yes, there are limitations on the powder coating of aluminum coils. Firstly, the thickness and quality of the aluminum coil can impact the effectiveness of the powder coating process. If the coil is too thin or of low quality, it may not be able to withstand the heat required for the powder coating process, leading to distortion or damage to the coil. Additionally, the surface preparation of the aluminum coil is crucial for successful powder coating. Any contaminants or impurities on the surface, such as oils, dirt, or oxides, can interfere with the adhesion of the powder coating. Proper cleaning and pre-treatment of the surface is necessary to ensure a smooth and durable coating. Furthermore, the size and shape of the aluminum coil may also pose limitations. Complex shapes or intricate designs may be challenging to coat evenly, resulting in variations in coating thickness or coverage. It may require special techniques or equipment to ensure a uniform and consistent coating. Finally, the choice of powder coating material may impact the limitations. Certain powder coatings may not be suitable for use on aluminum coils due to chemical compatibility issues or inadequate adhesion properties. It is important to select a powder coating material specifically designed for use on aluminum substrates. Overall, while powder coating is a popular and effective method for coating aluminum coils, there are limitations that need to be considered. Proper surface preparation, substrate quality, and coating material selection are crucial factors to ensure a successful and durable powder coating finish.

- Q: Are aluminum coils suitable for HVAC ductwork?

- Yes, aluminum coils are suitable for HVAC ductwork. Aluminum is a lightweight, durable, and corrosion-resistant material, making it an ideal choice for HVAC ductwork. It offers excellent heat transfer properties and is commonly used in both residential and commercial HVAC systems.

- Q: How do aluminum coils compare to steel coils in terms of strength?

- Significant differences can be observed between aluminum coils and steel coils in terms of strength. Generally speaking, steel coils exhibit greater strength and durability when compared to their aluminum counterparts. This can be attributed to steel's renowned high tensile strength and ability to withstand heavy loads, making it the favored selection for applications that prioritize strength and durability. Conversely, aluminum coils possess a lower strength in comparison to steel. Aluminum, as a lightweight metal, exhibits a lower tensile strength, implying that it may not offer the same resistance to heavy loads or stress as steel coils. Nonetheless, aluminum coils boast other advantageous properties, including exceptional corrosion resistance and high thermal conductivity. The decision to opt for either aluminum or steel coils relies on the specific application and its requirements. If strength and durability take precedence, steel coils are generally the superior choice. However, if weight reduction, corrosion resistance, or thermal conductivity are of greater importance, aluminum coils may be the preferred option.

- Q: Domestic production of color coated aluminum coil manufacturers which good?

- Color coated aluminum coil has two kinds of polyester color coating and fluorocarbon coating.

Send your message to us

Aluminum Coil Wholesale from China Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords