Alu Stock, Casting Coil Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

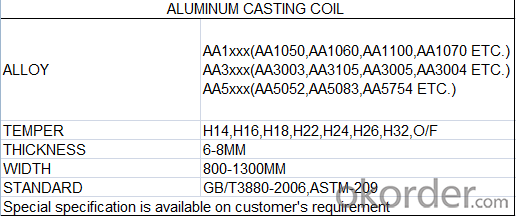

1.Structure of Alu Stock, Casting Coil Stock:

Alu Stock, Casting Coil Stock for thin coil and sheet is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of Alu Stock, Casting Coil Stockis about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Alu Stock, Casting Coil Stock :

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Alu Stock, Casting Coil Stock

4. Production Process of Alu Stock, Casting Coil Stock

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Casting Coil

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: What are the thermal expansion properties of aluminum coils?

- The thermal expansion properties of aluminum coils refer to how the dimensions of the coils change with variations in temperature. Aluminum is known for its relatively high coefficient of thermal expansion, meaning it expands and contracts more significantly compared to other materials when subjected to temperature changes. The coefficient of thermal expansion for aluminum is approximately 22.2 x 10^-6 per degree Celsius. This means that for every degree increase in temperature, the length, width, and thickness of the aluminum coils will increase by approximately 22.2 parts per million. Conversely, when the temperature decreases, the coils will contract accordingly. These thermal expansion properties have important implications in various applications where aluminum coils are used. For example, in heating and cooling systems, the expansion and contraction of aluminum coils due to temperature changes need to be carefully considered to ensure proper functioning and prevent damage. Similarly, in construction, where aluminum coils are often used for roofing and cladding, understanding their thermal expansion properties is crucial for avoiding structural issues and maintaining the integrity of the building. It is important to note that the coefficient of thermal expansion may vary slightly depending on the specific alloy of aluminum used in the coils. Additionally, other factors such as the thickness and shape of the coils can also influence the thermal expansion behavior. Therefore, when working with aluminum coils, it is advisable to consult the material specifications or consult with experts to accurately determine the thermal expansion properties and account for them in the design and application processes.

- Q: Can aluminum coils be used for industrial piping?

- Yes, aluminum coils can be used for industrial piping. Aluminum is a versatile and lightweight material that offers several advantages for industrial piping applications. It has excellent corrosion resistance, which makes it suitable for various industries, including chemical, petrochemical, and food processing. Aluminum coils are also easy to work with and can be formed into different shapes and sizes, allowing for flexibility in designing and installing piping systems. Additionally, aluminum has good thermal conductivity, which is beneficial for applications that require heat transfer. However, it is important to consider the specific requirements of the industrial process and consult with experts to ensure that aluminum coils are suitable for the intended application.

- Q: Are aluminum coils suitable for insulation jacketing?

- Yes, aluminum coils are suitable for insulation jacketing. Aluminum is a popular choice for jacketing material due to its excellent thermal properties, durability, and corrosion resistance. It is widely used in various industries, including HVAC, oil and gas, and petrochemical, for insulating pipe systems and equipment. Aluminum coils provide a protective covering around insulation materials, preventing moisture ingress and maintaining thermal efficiency. Additionally, their lightweight nature makes them easy to install and transport. Overall, aluminum coils are a reliable and effective solution for insulation jacketing applications.

- Q: Aluminum is a metal and nitrate (nitrogen) is a non metal so shouldn't they form an ionic bond and not a covalnt bond? And if it were an ionic bond wouldn't it be called aluminum mononitrate? But it is a covalnt bond (thus a molecular bond and so there is no mono in the name). Pleas help I'm very confused!

- The questioner probably means aluminium nitride, AlN, which has substantial covalent character due to massive polarisation of the large nitride ions by the small and highly charged Al3+ ions.

- Q: This question asks for methods to preserve the lifespan of an aluminum coil.

- <p>To maintain an aluminum coil and ensure its longevity, follow these steps: Store the coil in a cool, dry place away from moisture and direct sunlight. Keep it clean by regularly removing dust and debris. Avoid scratching or denting the coil's surface. Handle the coil carefully to prevent damage. Use appropriate lubricants when necessary to reduce friction. Regularly inspect the coil for any signs of corrosion or wear and address these issues promptly. By following these practices, you can extend the life of your aluminum coil and maintain its quality.</p>

- Q: Are aluminum coils suitable for food storage containers?

- Aluminum coils are indeed appropriate for food storage containers. This material is highly favored for such containers because of its many beneficial qualities. To begin with, aluminum is lightweight, which makes it easy to handle and transport. Moreover, it possesses excellent thermal conductivity, allowing for quick heating or cooling, making it perfect for storing both hot and cold food. Additionally, aluminum is resistant to corrosion and does not react with acidic or alkaline foods, ensuring that the taste and quality of the food remain unaffected. Furthermore, aluminum is an environmentally friendly choice as it is sustainable and can be recycled. However, it is worth noting that aluminum containers should be coated with a food-grade lining to prevent any potential interaction between the metal and the food, particularly with acidic foods. In conclusion, aluminum coils are a suitable option for food storage containers due to their lightweight nature, thermal conductivity, resistance to corrosion, and recyclability.

- Q: Why does the hollow aluminium rolling shutter door fall off for a long time?

- The series of HO profiles is heated by Doyle's Aluminum Alloy bar by extrusion forming production, use the 6063 Aluminum Alloy material, has excellent plasticity, corrosion resistance, toughness, easy polishing, film.

- Q: Are aluminum coils suitable for HVAC ductwork?

- Yes, aluminum coils are suitable for HVAC ductwork. Aluminum coils are preferred for HVAC ductwork due to their lightweight and corrosion-resistant properties. They are highly durable and can withstand extreme temperatures and weather conditions. Additionally, aluminum coils have excellent thermal conductivity, which allows for efficient heat transfer and ensures optimal cooling or heating performance. Moreover, aluminum is a non-toxic material, making it safe for use in HVAC systems. Overall, aluminum coils are an ideal choice for HVAC ductwork, providing long-lasting performance and energy efficiency.

- Q: What are the different coil annealing options available for aluminum coils?

- There are several coil annealing options available for aluminum coils, including batch annealing, continuous annealing, and stress relief annealing. Batch annealing involves heating the coils in a controlled atmosphere furnace and then allowing them to cool slowly. Continuous annealing, on the other hand, involves passing the coils through a series of induction or gas-fired heating zones with controlled cooling. Stress relief annealing is a process used to relieve internal stresses in the coils, typically performed at a lower temperature for a longer duration.

- Q: How are aluminum coils used in insulation applications?

- Due to their excellent thermal conductivity and durability, aluminum coils find common use in insulation applications. These coils are frequently employed in the production of air conditioning units, heat pumps, and refrigeration systems to effectively transfer heat, enabling efficient cooling or heating of a space. Aluminum is the preferred material for these coils due to its high thermal conductivity, which allows for efficient heat transfer. Moreover, aluminum is lightweight and corrosion-resistant, ensuring durability and longevity, making it an ideal choice for applications that require these qualities. To create a thermal barrier, aluminum coils are often combined with other insulation materials like foam or fiberglass. This combination helps minimize heat transfer between the inside and outside of a building, ultimately reducing energy consumption and improving overall energy efficiency. Additionally, aluminum coils can be easily molded into various shapes and sizes, providing flexibility and customization options for insulation purposes. This versatility makes them suitable for a wide range of insulation needs, whether in residential, commercial, or industrial settings. In conclusion, aluminum coils play a vital role in insulation applications by efficiently transferring heat and contributing to energy efficiency. Their thermal conductivity, durability, and versatility make them an ideal choice for various insulation needs, ultimately helping in the creation of comfortable and energy-efficient environments.

Send your message to us

Alu Stock, Casting Coil Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords