Wood Grain Aluminum Coil Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Foil Stock used for Aluminum Coil

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Aluminum Foil Stock used for Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Foil Stock used for Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

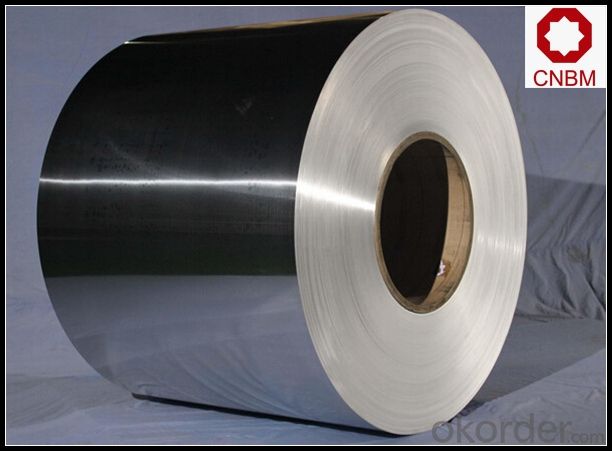

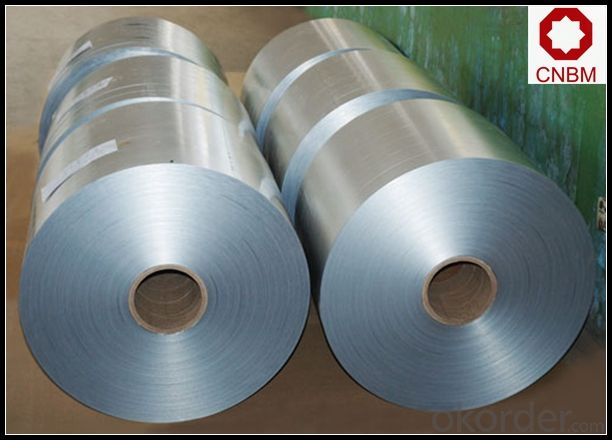

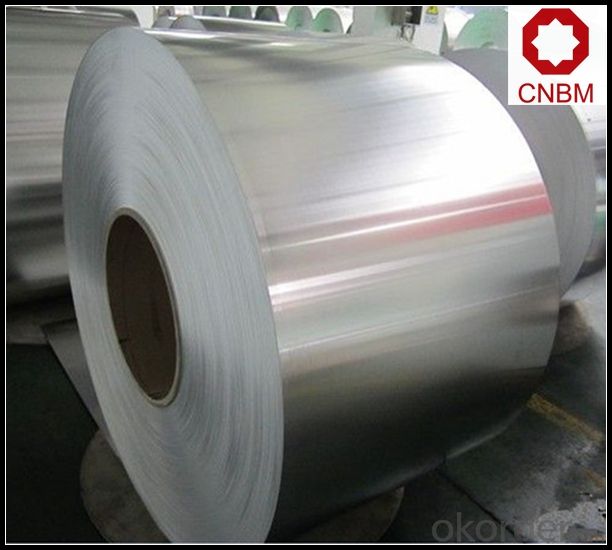

5. Image of Aluminum Foil Stock used for Aluminum Coil

6. Package and shipping of Aluminum Foil Stock used for Aluminum Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ of

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are parakeets allergic to aluminum because I wanted to use a metal pie pan for a bird bath.

- ask a nice bird vet

- Q: How many atoms are there in a piece of aluminum foil, 7.3 inches in length and 12.0 inches in width, and 0.141 mm thick? According to this problem, aluminum foil is a flat-rolled product, rectangular in cross section, of thickness from 0.006(0.15mm) to 0.00025(0.006mm). The density of Al is 2.699 g/cm3.

- the nice and cozy button is Avogadro' sort that's 6.0226 x 10^23 atoms consistent with mole So if the cost of the Al roll is $2.fifty two for one lb Then proceed as follows: a million lb = 454 gms At Wt Al = 26.ninety 8 gms consistent with mole Moles of Al in a million lb = 454/26.ninety 8 = sixteen.80 two moles sort of atms of Al = sixteen.80 two x 6.0226 x 10^23 = a million.013 x 10^25 cost consistent with atom = $2.fifty two / a million.013 x 10^25 = $2.2847 x 10^-25 consistent with atom or 0.0000000000000000000000228 cents consistent with atom. BTW, you probably did no longer finished specify the situation - how thick is teh Al foil? In any journey Al atoms are enormously inexpensive. desire this helps

- Q: Explain how aluminum coils impact the manufacturing process.

- <p>Aluminum coils significantly affect the production process by offering versatility and efficiency. They are easily formed, cut, and shaped, which streamlines manufacturing. Their lightweight nature reduces the energy consumption in transportation and handling. Additionally, aluminum coils' corrosion resistance and durability reduce waste and the need for frequent replacements, enhancing sustainability. They also contribute to the production of various products, such as automotive parts, construction materials, and packaging, by providing a consistent and high-quality material.</p>

- Q: What is the elongation of aluminum coils?

- The elongation of aluminum coils refers to the degree to which the coils can be stretched or lengthened before they reach their breaking point. It is a measure of the material's ductility or ability to undergo plastic deformation without fracturing. Aluminum coils typically have a high elongation percentage, typically ranging from 10% to 30%, which means they can be stretched considerably before breaking. This property makes aluminum coils suitable for various applications where flexibility and resilience are required, such as in the manufacturing of electrical cables, automotive parts, and building materials.

- Q: Are aluminum coils suitable for signage applications?

- Yes, aluminum coils are suitable for signage applications. They are durable, lightweight, and resistant to corrosion, making them ideal for outdoor signage. Additionally, aluminum coils can be easily shaped and molded, allowing for various design possibilities in signage applications.

- Q: Can aluminum coils be used in power generation facilities?

- Yes, aluminum coils can be used in power generation facilities. Aluminum is a highly conductive material that offers several advantages for power generation applications. It has excellent thermal conductivity, meaning it can efficiently transfer heat away from the coils, which is crucial for cooling systems in power generation facilities. Additionally, aluminum is lightweight, making it easier to handle and install compared to other metals like copper. This lightweight property also reduces the overall weight of the equipment, resulting in cost savings. Furthermore, aluminum is corrosion-resistant, which is important for power generation facilities that often operate in harsh environments. Overall, aluminum coils are a viable option for power generation facilities due to their conductivity, thermal efficiency, lightweight nature, and corrosion resistance.

- Q: What are the common surface treatments for aluminum coils in the construction industry?

- In the construction industry, aluminum coils are widely used due to their lightweight, durability, and corrosion resistance. To enhance their performance and aesthetic appeal, various surface treatments are applied to aluminum coils. Some of the common surface treatments for aluminum coils in the construction industry include: 1. Anodizing: Anodizing is a widely used surface treatment that involves creating an oxide layer on the aluminum surface. This process provides enhanced corrosion resistance, improves weather resistance, and allows for coloring options. 2. Powder coating: Powder coating is a popular surface treatment method where a dry powder is electrostatically applied to the aluminum coil and then cured under heat. This results in a durable, smooth, and attractive finish that is resistant to chipping, fading, and scratching. 3. PVDF coating: Polyvinylidene fluoride (PVDF) coating is a high-performance coating that provides excellent weather resistance and color retention. It is commonly used in architectural applications where long-term durability and aesthetic appeal are desired. 4. Paint coating: Traditional liquid paint coatings are also applied to aluminum coils, providing a wide range of color options and finishes. Paint coatings offer good corrosion resistance and can be customized to meet specific design requirements. 5. Brushed finish: Brushing the aluminum surface creates a textured finish that gives a unique appearance to the coils. The brushed finish can be achieved using mechanical or chemical processes, enhancing the aesthetic appeal of the aluminum coils. 6. Laminating: Laminating is a surface treatment method where a layer of protective film or laminate is applied to the aluminum coil. This protects the coil from scratches, stains, and other damage during handling, transportation, and installation. These surface treatments not only enhance the durability and performance of aluminum coils but also provide options for customization, allowing architects and designers to achieve their desired aesthetics while ensuring long-lasting performance in construction applications.

- Q: Supposably water ozidies it what ever that means so how in the world do i clean an aluminum bike if i cant use water? i like to use water and soap on my carbon bike so what do i use on a aluminum?

- For painted metal, supports, grips, vinyl seat, tires and spokes, use a solution of 1-part Simple Green to 30-parts water — spray onto soiled areas. Wipe immediately with damp cloth to rinse, followed by dry towel — making sure to completely dry the area cleaned. My point is to show that you are supposed to cut the Simple Green with 30 parts of water. MOST people don't do this step. Simple Green (and many other cleaners) are very concentrated. NEVER clean a bicycle with this kind of cleaner without proper dilution. Read labels. Follow directions. Full strength Simple Green has enough butyl solvent to corrode bare aluminum on brake surfaces on wheels and if the wheel is too wet it can actually melt the glue of the rim strip by seeping in the spoke holes. I have seen this at bike shops a lot. The cleaner (if sprayed full strength around bearings) over spray has the potential to break down the grease -- after all it is a degreaser. Always dampen a cloth or sponge in your cleaning solution and wipe down a bike. Don't spray it.

- Q: How do aluminum coils contribute to the electrical conductivity of products?

- Aluminum coils are widely used in electrical applications due to their excellent conductivity properties. The electrical conductivity of aluminum is high, making it an ideal material for transmitting and distributing electrical power. When aluminum coils are used in products, they facilitate the flow of electric current. Aluminum has a low resistance to the flow of electricity, allowing for efficient transmission of electrical energy. This low resistance ensures minimal power loss during transmission, which is critical in maintaining the efficiency of electrical systems. Additionally, aluminum coils have a high thermal conductivity, allowing them to quickly dissipate heat generated during the transmission of electrical current. This is crucial in preventing overheating and maintaining the stability and longevity of electrical products. The lightweight nature of aluminum also contributes to its suitability in electrical applications. Its low density makes it easier to handle and install, reducing the overall weight of products and making them more portable. Overall, aluminum coils play a significant role in enhancing the electrical conductivity of products. Their high conductivity, low resistance, and excellent thermal properties make them a preferred choice in a wide range of electrical applications, including power transmission lines, electrical cables, motors, transformers, and other electrical devices.

- Q: What is the typical lead time for ordering aluminum coils?

- The lead time for ordering aluminum coils can vary depending on factors such as the supplier, quantity ordered, and current market conditions. Typically, lead times for aluminum coils can range from a few weeks to several months. If the supplier has the coils readily available in their stock, the lead time can be relatively short, usually around 2-4 weeks. This is the case when the supplier consistently maintains inventory and has the desired specifications and quantities ready for immediate shipment. However, if the coils need to be customized or if the supplier lacks sufficient stock, the lead time can be longer. Customizing aluminum coils may require additional processing time, such as rolling, annealing, or coating, which can extend the lead time by a few weeks or even months. Moreover, lead times can be influenced by market conditions and demand fluctuations. When there is high demand or disruptions in the supply chain, lead times may increase due to limited availability of raw materials or production capacity. For a more accurate estimate of the lead time for ordering aluminum coils, it is advisable to directly contact the specific supplier or manufacturer. They can provide detailed information based on their current inventory, production capabilities, and any other factors that may impact lead times.

Send your message to us

Wood Grain Aluminum Coil Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords