Aluminum Coil Stock For Gutters

Aluminum Coil Stock For Gutters Related Searches

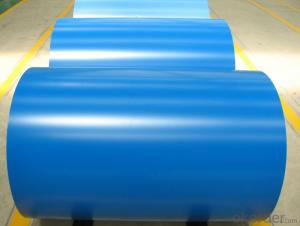

Aluminum Gutter Coil Stock Aluminum Gutter Coil For Sale Aluminum Gutter Coil Aluminum Coil Stock For Sale Gutter Aluminum Coil Aluminum Gutter Coil Prices Aluminum Coil Stock Gauge Aluminum Gutter Coil Wholesale Coil Aluminum Stock Wood Grain Aluminum Coil Stock Aluminum Gutter Coil Suppliers Aluminum Trim Coil Stock Coil Stock Aluminum Aluminum Siding Coil Stock Mill Finish Gutter Coil Stock Aluminum Coil Stock Thickness Anodized Aluminum Coil Stock Vinyl Coated Aluminum Coil Stock Aluminum Coil Stock Brake Aluminum Coil Stock Prices Colored Aluminum Coil Stock Painted Aluminum Coil Stock Pvc Coated Aluminum Coil Stock Aluminum Coil Stock Suppliers Alcoa Aluminum Coil Stock Buy Aluminum Coil Aluminum Coil Stock Lowe's Aluminum Coil Stock Holder White Aluminum Coil Stock Aluminum Foil StockAluminum Coil Stock For Gutters Supplier & Manufacturer from China

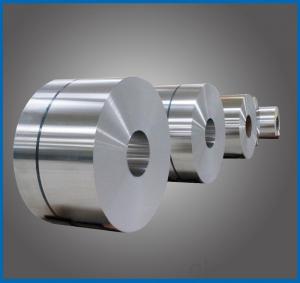

Aluminum Coil Stock For Gutters is a versatile product that is widely used in the construction industry for various purposes. This product is known for its durability, corrosion resistance, and lightweight properties, making it an ideal choice for gutter systems. The aluminum coil stock is designed to provide a seamless and efficient water drainage system, ensuring that water is effectively channeled away from buildings and structures, thus preventing water damage and maintaining the integrity of the construction.In terms of application and usage scenarios, Aluminum Coil Stock For Gutters is used in both residential and commercial construction projects. It is particularly popular for its ability to withstand harsh weather conditions, such as heavy rain and snow, without losing its shape or integrity. This makes it a preferred choice for regions with extreme weather fluctuations. Additionally, the product's ease of installation and low maintenance requirements make it a cost-effective solution for contractors and homeowners alike.

Okorder.com is a reputable wholesale supplier of Aluminum Coil Stock For Gutters, boasting a large inventory to cater to the varying needs of customers. As a leading supplier in the industry, Okorder.com ensures that their products meet the highest quality standards and are available at competitive prices. Their extensive inventory allows them to provide a wide range of options for customers, ensuring that they can find the perfect aluminum coil stock to suit their specific gutter system requirements.

Hot Products