Color Aluminum Coil Stock for Aluminum Coil Gutter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Coil Stock used for Aluminum Coil Gutter

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Aluminum Coil Stock used for Aluminum Coil Gutter

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Coil Stock used for Aluminum Coil Gutter

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

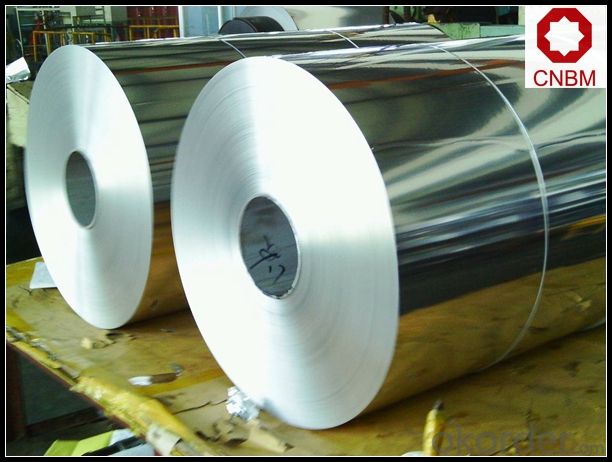

5. Image of Aluminum Coil Stock used for Aluminum Coil Gutter

6. Package and shipping of Aluminum Coil Stock used for Aluminum Coil Gutter

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ of

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the safety considerations when handling aluminum coils?

- When working with aluminum coils, it is crucial to take several safety factors into consideration. To begin with, it is essential to understand that aluminum coils can be quite heavy, particularly when dealing with larger sizes. Therefore, it is important to employ correct lifting techniques to prevent strain or injury to the back and muscles. This may involve using lifting aids or seeking assistance from others when moving or positioning the coils. Furthermore, aluminum coils may have sharp edges or corners that can cause cuts or puncture wounds if not handled with care. It is advisable to wear suitable personal protective equipment, such as gloves, to protect against potential injuries while handling the coils. In addition, aluminum is an excellent conductor of both electricity and heat. Consequently, it is of utmost importance to ensure that the coils do not come into contact with live electrical sources or come into close proximity to open flames or intense heat. This precautionary measure can help prevent electrical shocks or fires, which present significant safety risks. Moreover, proper storage and stacking of aluminum coils play a crucial role in accident prevention. Coils should be stored in a stable and secure manner to avoid the risk of falling or rolling over. Employing appropriate stacking techniques, such as using suitable supports or pallets, is essential to prevent toppling. Finally, it is imperative to be familiar with any specific safety guidelines or regulations provided by the manufacturer or relevant authorities when working with aluminum coils. Adhering to these guidelines ensures the safe handling and use of the coils, minimizing the risk of accidents or injuries. To summarize, the safety considerations when handling aluminum coils involve employing correct lifting techniques, wearing personal protective equipment, avoiding contact with electrical sources and heat, ensuring proper storage and stacking, and following manufacturer guidelines. Implementing these precautions significantly reduces the risk of accidents or injuries.

- Q: How should aluminum coil be stored to maintain its quality and prevent damage?

- <p>The best way to store aluminum coil involves several key practices: Store the coil in a clean, dry, and well-ventilated area to prevent moisture and dirt accumulation. Ensure the storage area is free from corrosive substances and temperature fluctuations. Use pallets or racks to keep coils off the ground, and avoid stacking heavy items on top. Protect coils with plastic covers or wrapping to prevent dust and scratches. Organize coils by size, type, and grade for easy access and to prevent damage during handling. Regularly inspect stored coils for signs of damage or corrosion and rotate stock to minimize prolonged storage of any single coil.</p>

- Q: What are the potential applications of perforated aluminum coils?

- Due to their unique characteristics and versatility, perforated aluminum coils have the potential for a wide range of applications. Here are some of the possible uses of these coils: 1. In architectural projects, perforated aluminum coils can be employed for facades, sunscreens, and cladding systems. The perforations not only create visually pleasing designs but also provide ventilation and sun control. 2. The perforated holes in aluminum coils make them suitable for use as filters in various applications, such as air, liquid, or gas filtration systems. They effectively remove contaminants while maintaining an efficient flow. 3. Perforated aluminum coils can be integrated into industrial equipment like heat exchangers, condensers, and evaporators. The perforations aid in heat transfer, contributing to efficient cooling or heating processes. 4. The automotive industry can benefit from the lightweight and durable nature of perforated aluminum coils. They can be utilized in the manufacturing of automobile parts, including grilles, radiator covers, and engine components, providing both functionality and aesthetic appeal. 5. Aluminum coils with perforations can assist in sound absorption and noise reduction, making them suitable for the construction of acoustic panels in auditoriums, theaters, recording studios, and other spaces where sound quality is important. 6. Perforated aluminum coils can be used for decorative purposes in interior design projects. They can be shaped into screens, room dividers, or wall panels, adding visually appealing patterns and a touch of modernity to spaces. 7. In the agricultural sector, perforated aluminum coils can find applications in crop protection systems. They allow for controlled air circulation while protecting plants from pests or excessive sunlight. 8. The perforations in aluminum coils can be advantageous for energy-efficient applications. They can be incorporated into solar panels, allowing light to pass through while maintaining structural integrity. In summary, perforated aluminum coils have a wide range of potential applications in architecture, filtration, industrial equipment, automotive, acoustic panels, decoration, agriculture, and energy-efficient solutions. Their versatility, lightweight, durability, and aesthetic appeal make them a popular choice for various uses across different industries.

- Q: Are aluminum coils applicable in the manufacturing process of automobiles?

- <p>Yes, aluminum coils are widely used in automobile manufacturing. They are utilized in various components such as engine parts, body panels, and wheels due to their lightweight, corrosion resistance, and strength. Aluminum's recyclability and energy efficiency also make it an environmentally friendly choice for the automotive industry.</p>

- Q: i know aluminum nitrate will dissociate, and also that there is no way that the nitrate will react to make the solution basic or neutral. But what about the aluminum ion? Does it take OH- from water to make [Al(OH)4]- and make the solution acidic? Does it somehow take protons and make a basic solution? My teacher said its not neutral, so I'm leaning towards an acidic solution. Thanks!

- Aluminum nitrate is the salt produced by the reaction of aluminum hydroxide and nitric acid. Nitric acid is a strong acid. Aluminum hydroxide is a realtively weak base. So the salt will be acidic.

- Q: What is the primary function or use of a spring steel wire coil?

- <p>A spring steel wire coil is primarily used for its high elasticity and strength. It is designed to return to its original shape after being deformed, which makes it ideal for applications requiring resilience and durability. Common uses include the manufacturing of various types of springs, such as compression springs, torsion springs, and extension springs, found in automotive suspensions, mechanical devices, and industrial equipment. The coil's properties also make it suitable for applications in furniture, electronics, and other industries where a reliable and consistent force is needed.</p>

- Q: What is the typical thickness tolerance for aluminum coils?

- The typical thickness tolerance for aluminum coils can vary depending on the specific requirements and industry standards. However, in general, the typical thickness tolerance for aluminum coils is often specified within a range of +/- 0.002 to 0.005 inches. This means that the actual thickness of the aluminum coil can deviate from the specified thickness by a maximum of either 0.002 or 0.005 inches, depending on the specific tolerance requirements. It is important to note that these tolerances can also be expressed as a percentage of the specified thickness, typically ranging from 4% to 8%. These tolerances ensure that the thickness of the aluminum coil meets the desired specifications and allows for a certain level of variation that is within acceptable limits for the intended application.

- Q: Relevant question 5Excuse me, what's the meaning of your "deoiling effect"? And you answer two kinds of performance, my understanding is that the oil removal effect is not good, lead to aluminum volume is not neat, what is the difference between the two? Solution, thank you

- when this phenomenon occurs in feeding occurs when you say the phenomenon, when parking tension shock or mutation, the inner drum contraction material, inner sleeve trace diameter decreases, emergency stop when the inertia torque increase, will influence on the oil film, and is the inner bag sleeve is not tight, causing the inner diameter decreases due to aluminum transfer from the inner ring to slide staggered, outer ring, the outer ring can be transferred to the volume of the material into a neat is not neat, not fully delivered appeared loose layer.

- Q: Are aluminum coils suitable for heat sinks?

- Indeed, aluminum coils are well-suited for heat sinks. The reason for aluminum's popularity in this regard lies in its exceptional thermal conductivity and affordability. Its remarkable thermal conductivity permits efficient heat transfer from a heat source to the heat sink's fins, which effectively dissipate the heat into the surrounding environment. Moreover, aluminum possesses the advantageous qualities of being lightweight and easily moldable into different shapes, thereby rendering it a versatile material for heat sink purposes. All in all, aluminum coils prove to be a fitting option for heat sinks due to their ability to effectively dissipate heat and their cost-effectiveness.

- Q: This question is asking for methods or strategies to protect aluminum coils from rusting.

- <p>To prevent aluminum coil from rusting, it's important to understand that aluminum doesn't rust like iron does; it forms a protective oxide layer that prevents further corrosion. However, to maintain the integrity of the aluminum coil and prevent other forms of degradation, you can: 1. Store the coils in a dry environment to avoid moisture-induced corrosion. 2. Apply a protective coating or lacquer to the surface. 3. Use anti-corrosion packaging materials during transportation and storage. 4. Regularly inspect the coils for any signs of damage or corrosion and address them promptly. 5. Avoid contact with aggressive chemicals that can break down the protective oxide layer. Proper handling and storage are key to maintaining the quality of aluminum coils.</p>

Send your message to us

Color Aluminum Coil Stock for Aluminum Coil Gutter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords