Black Aluminum Coil Stock for Color Coated Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminum Coil for Curtain Walls

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Color Coated Aluminum Coil for Curtain Walls

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminum Coil for Curtain Walls

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

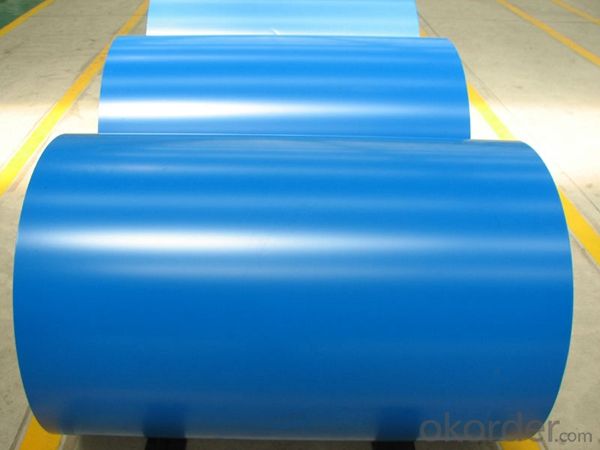

5. Image of Color Coated Aluminum Coil for Curtain Walls

6. Package and shipping of Color Coated Aluminum Coil for Curtain Walls

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the role of aluminum coils in the construction of sports stadiums?

- Due to their advantageous properties, aluminum coils play a vital role in the construction of sports stadiums. Primarily, aluminum's lightweight nature makes it an excellent option for large-scale structures like stadiums. By utilizing aluminum coils during stadium construction, transportation and installation become easier, resulting in reduced construction time and costs. Moreover, aluminum possesses high resistance against corrosion, which is particularly advantageous in outdoor environments where stadiums are exposed to harsh weather conditions. This corrosion resistance ensures the longevity and durability of the stadium's structure, thereby minimizing maintenance and repair expenses over time. Furthermore, aluminum coils exhibit exceptional thermal conductivity, allowing for efficient heat transfer and effective temperature regulation within the stadium. This feature becomes especially significant in modern stadiums that require climate control systems to ensure the comfort of both players and spectators. Additionally, aluminum's high malleability enables it to be easily shaped into various forms and sizes, offering flexibility in stadium design and construction. This versatility empowers architects and engineers to create innovative and visually appealing structures, ultimately enhancing the overall aesthetic experience for visitors. In conclusion, aluminum coils play a multifaceted role in the construction of sports stadiums. They provide a lightweight, corrosion-resistant, thermally conductive, and malleable material that facilitates efficient construction, durability, comfort, and aesthetic appeal.

- Q: Can aluminum coils be painted or printed on?

- Yes, aluminum coils can be painted or printed on. Aluminum is a versatile material that can be coated or painted to achieve various finishes and colors. The surface of aluminum coils can be prepared through a process called pre-treatment, which involves cleaning, etching, and applying a primer. This prepares the surface for painting or printing. Painting aluminum coils involves applying a coating system that typically consists of a primer, a color coat, and a topcoat for protection. The paint can be applied using various methods such as spraying, roll coating, or coil coating. Coil coating, in particular, is a commonly used method where the paint is applied to the coil before it is formed into the desired shape. This ensures a uniform and consistent finish. Printing on aluminum coils is also possible using different techniques such as screen printing, digital printing, or lithography. These methods allow for detailed designs, patterns, or even photographs to be printed onto the surface of the aluminum coil. It is important to note that the choice of paint or printing method may depend on the specific requirements of the application, such as durability, weather resistance, or aesthetic preferences. Additionally, proper surface preparation, selection of suitable coatings, and adherence to recommended application guidelines are essential for ensuring a successful and long-lasting paint or print finish on aluminum coils.

- Q: What are the different coil slitting widths available for aluminum coils?

- The specific requirements and industry standards determine the various coil slitting widths available for aluminum coils. The width range for slitting aluminum coils can vary from as narrow as 0.5 inches to as wide as 72 inches or more. The coil slitting facility's equipment and capabilities determine the exact range of available widths. These widths are tailored for different applications and industries, including automotive, construction, packaging, and electronics. Common coil slitting widths for aluminum coils are 12 inches, 24 inches, 36 inches, and 48 inches. However, it is essential to note that custom slitting widths can be requested to meet unique project needs.

- Q: Are aluminum coils suitable for architectural cladding applications?

- Yes, aluminum coils are suitable for architectural cladding applications. Aluminum is lightweight, durable, and corrosion-resistant, making it an ideal material for cladding buildings. It can be easily formed into various shapes and sizes, allowing for creative and unique designs. Additionally, aluminum coils offer excellent weather resistance, low maintenance requirements, and a wide range of color options, making them a popular choice in architectural cladding projects.

- Q: Are there any specific guidelines for the handling of aluminum coils?

- Yes, there are specific guidelines for the handling of aluminum coils. These guidelines typically include proper lifting techniques, the use of appropriate equipment such as cranes or forklifts, and ensuring that the coils are stored in a clean and dry environment to prevent corrosion. It is also important to handle the coils gently to avoid any damage or deformation.

- Q: Can aluminum coils be used for radiation shielding?

- Yes, aluminum coils can be used for radiation shielding. Aluminum is a commonly used material for radiation shielding due to its high atomic number and density, making it effective at absorbing and scattering radiation. Aluminum can effectively shield against a wide range of radiation types, including gamma rays and X-rays. Additionally, aluminum is a lightweight and malleable material, making it easy to work with and suitable for various applications where radiation shielding is required, such as in medical imaging, nuclear power plants, and aerospace industries.

- Q: What are the different surface treatments available for aluminum coils?

- There are several surface treatments available for aluminum coils, each with its own benefits and applications. Some of the common surface treatments include: 1. Mill Finish: This is the standard untreated surface of aluminum coils. It has a dull appearance and is suitable for applications where aesthetics are not a priority, such as industrial or structural uses. 2. Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum coils. This treatment enhances the corrosion resistance, durability, and appearance of the coils. Anodized aluminum coils are commonly used in architectural applications, such as building exteriors or window frames. 3. Paint Coating: Aluminum coils can be coated with various paints to improve their appearance, protect against corrosion, and provide additional functionality such as heat reflection or insulation. Paint coatings can be applied in different thicknesses and finishes, ranging from standard coatings for general use to specialized coatings for specific applications like automotive or aerospace industries. 4. Brushed Finish: This treatment involves brushing the surface of aluminum coils with abrasive materials to create a textured finish. Brushed aluminum coils have a distinct pattern and are often used in decorative applications, interior design, or signage. 5. Embossed Finish: Aluminum coils can be embossed with patterns or textures to enhance their appearance or improve their functionality. The embossing process alters the surface of the coils, creating a raised or recessed design. Embossed aluminum coils are commonly used in architectural, automotive, or packaging applications. 6. Laminating: Aluminum coils can be laminated with various materials, such as films or foils, to provide additional protection, insulation, or decorative effects. This treatment can enhance the appearance, durability, or functionality of the coils, depending on the type of laminating material used. These are just a few examples of the surface treatments available for aluminum coils. The choice of treatment depends on the specific requirements of the application, such as aesthetics, corrosion resistance, durability, or functionality. It is important to select the appropriate surface treatment to ensure the desired performance and longevity of the aluminum coils in their intended use.

- Q: Are aluminum coils suitable for gutter systems?

- Yes, aluminum coils are suitable for gutter systems. Aluminum is a popular choice for gutter systems due to its durability, lightweight nature, and resistance to rust and corrosion. It is a cost-effective option that can withstand harsh weather conditions and has a long lifespan. Additionally, aluminum coils are easy to install and maintain, making them an ideal choice for gutter systems.

- Q: Are aluminum coils suitable for food and beverage packaging?

- Yes, aluminum coils are suitable for food and beverage packaging. Aluminum is a versatile material that offers various advantages for packaging applications. It is lightweight, making it easy to transport and handle. Aluminum is also highly resistant to corrosion, which ensures that the packaging remains intact and protects the contents from external factors. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat transfer, which is beneficial for food and beverage products that require temperature control. It is also impermeable to light, moisture, and oxygen, providing an excellent barrier to maintain the quality and freshness of the packaged items. Furthermore, aluminum is recyclable and can be reused, making it an environmentally friendly choice for packaging. Overall, aluminum coils are a reliable and suitable option for food and beverage packaging due to their durability, protective properties, and sustainability.

- Q: Can the little can opening cap things on an aluminum can be recycled? My friend told me if you fill a two liter bottle with them you can get loads of cash. Is this true?

- Yes. Aluminium can be recycled. (watch the TV ad, UK) No. You would need tons of the stuff ( a tonne of copper is only around ?1000) They are usually colleced for charity. And they save up all the 2 litre bottles full! Feel the weight, aluminium is very light.

Send your message to us

Black Aluminum Coil Stock for Color Coated Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords