Black Aluminum Coil Stock for Cans with Bright Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product Description

Specification:

Hot Rolled Aluminium coil | ||||||||||||||||

Aluminium Coils, non-alloy and alloy products have many different applications, they are used windly throughout construction, building, decoration, lighting, metal nameplate, aircraft and aerospace structures, etc. | ||||||||||||||||

Specification | ||||||||||||||||

ALLOY | TEMPER | THICKNESS | WIDTH(mm) | LENGTH(mm) | ||||||||||||

1050,1060,1070, | O,F, H12, 114,H18,H22, H24,H26,H32, H34,H36,H111, | 3.0-10.0 | 1000--1500mm | in Coil | ||||||||||||

chemical composition | ||||||||||||||||

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.Al | |||

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.50 | |||

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.60 | |||

1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.70 | |||

1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.10 | - | - | - | 0.05 | 99.00 | ||||

3003 | 0.60 | 0.70 | 0.5-0.2 | 1.0-1.5 | - | - | - | 0.10 | - | - | - | 0.15 | 96.95-96.75 | |||

3004 | 0.30 | 0.70 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | 0.15 | 96.55-95.55 | |||

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden

pallets, waterproof paper and plastic coverage or or

as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance

payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

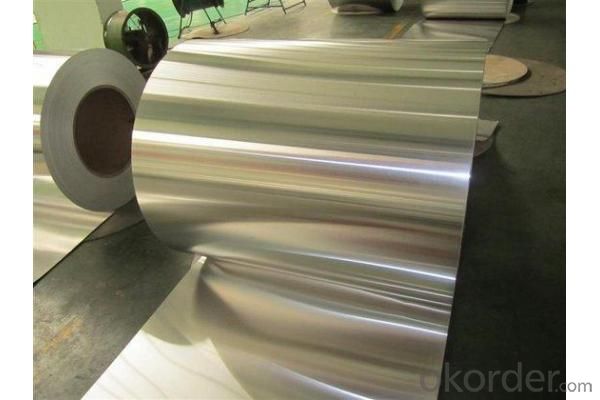

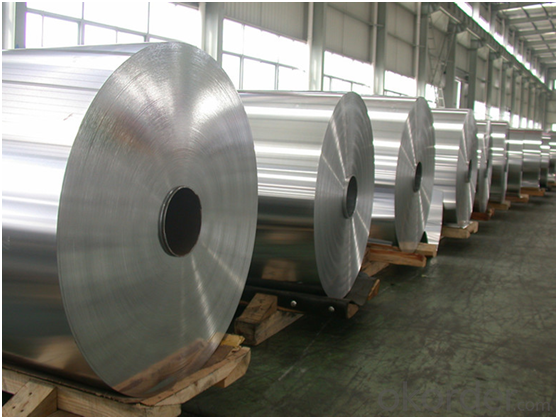

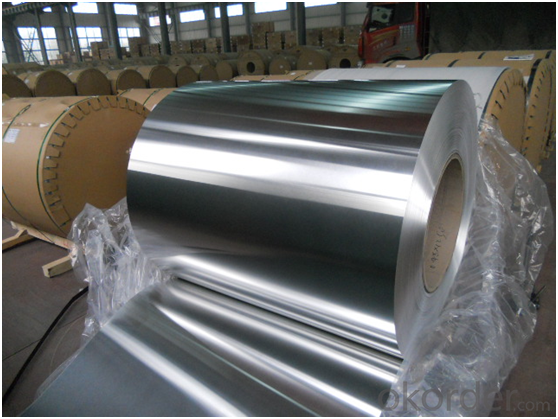

l Product Images

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact us

Email:service@okorder.com

- Q: Can aluminum material be utilized as a baking surface for bread?

- <p>Aluminum coils are not typically used for baking bread. While aluminum is a good conductor of heat and is used in baking sheets and muffin tins, it's usually in a flat, solid form. Aluminum coils, often used for industrial purposes like heat exchangers, are not designed for direct food contact. For baking bread, it's best to use materials specifically designed for baking, such as silicone mats, parchment paper, or non-stick baking sheets. These materials are safe for food contact and can withstand the high temperatures required for baking bread.</p>

- Q: The specification of thermal insulating aluminum coil

- 4-0 In general, the chemical engineering products for thermal insulation is 0. According to the International standard, the thickness tolerance is +-5%.02MM. according to industrial standard, it is +-0. The production crafts are embossed and plain sheet.

- Q: How do aluminum coils contribute to energy-efficient lighting?

- Aluminum coils play a crucial role in enhancing the energy efficiency of lighting systems. The primary advantage of using aluminum coils in lighting applications is their excellent thermal conductivity. Aluminum has a high thermal conductivity, which means it can efficiently transfer heat away from the light source and dissipate it into the surrounding environment. This property helps to prevent the overheating of lighting fixtures and ensures the longevity and efficiency of the lighting system. Furthermore, aluminum coils are lightweight and possess a high strength-to-weight ratio, making them ideal for creating compact and durable lighting fixtures. By using aluminum coils, manufacturers can design and produce lighter and more efficient lighting products, reducing the overall energy consumption. Additionally, aluminum coils are highly reflective, enabling them to efficiently distribute and reflect light. This characteristic allows for better light output and ensures that a larger portion of the emitted light is effectively utilized, reducing energy waste. Moreover, aluminum is a highly recyclable material, meaning it can be reused and repurposed multiple times without losing its qualities. The recyclability of aluminum coils contributes to the overall sustainability of energy-efficient lighting systems, reducing the environmental impact associated with their production and disposal. In summary, aluminum coils contribute to energy-efficient lighting by efficiently dissipating heat, reducing energy consumption through lightweight designs, optimizing light distribution, and promoting sustainability through recyclability.

- Q: Who knows Xingtai aluminum shutter door how much is one square meter?

- Two floor is right, you have to use a thick price on the high. A good job, 2012 way, is dead, and get a color to cope with it, ha ha.

- Q: Can aluminum coils be used for seamless gutters?

- Yes, aluminum coils can be used for seamless gutters. Aluminum is a popular choice for gutter systems due to its durability, lightweight nature, and resistance to corrosion. Aluminum coils are commonly used to create seamless gutters, which offer several advantages over traditional sectional gutters. Seamless gutters are custom-made on-site, ensuring a perfect fit for the specific dimensions of the building. This eliminates the need for seams, which can be prone to leaks and require regular maintenance. Additionally, aluminum is easy to work with, allowing for seamless gutters to be formed into various shapes to accommodate the unique design of a building. Overall, aluminum coils are a practical and efficient option for creating seamless gutters.

- Q: What is the typical coefficient of thermal expansion for aluminum coils?

- The typical coefficient of thermal expansion for aluminum coils is around 23.6 x 10^-6 per degree Celsius.

- Q: How much does it cost to extract aluminium from its raw ore? Also how much does extracted aluminium sell for? I cannot find this anywhere on the internet. I would really appreciate some help.

- The Cost Of Aluminium

- Q: Do aluminum coils require any special maintenance?

- Aluminum coils, like any other HVAC system components, do require regular maintenance to ensure optimal performance and longevity. While they may not require any specific special maintenance, they still need attention and care to function efficiently. Regular maintenance tasks for aluminum coils include cleaning, inspection, and occasional coil straightening. Cleaning the aluminum coils is crucial to remove dirt, dust, and debris that can accumulate on the surface over time. This buildup can restrict airflow and hinder heat transfer, reducing the overall efficiency of the system. Cleaning can be done using a soft brush or vacuum cleaner, ensuring that the fins and coils are not damaged in the process. Additionally, regular inspection of the aluminum coils is necessary to identify any signs of corrosion, leaks, or damage. Addressing these issues promptly can prevent further deterioration and costly repairs. It is recommended to check for any bent or damaged fins and straighten them if necessary to maintain proper airflow. Furthermore, it is essential to keep the surrounding area free from debris or vegetation that could obstruct airflow and cause the coils to work harder, leading to increased energy consumption and potential compressor damage. Regularly trimming vegetation and keeping the area clean will help maintain the coils' performance. Lastly, it is advisable to have a professional HVAC technician perform annual maintenance on your HVAC system, including the aluminum coils. They can conduct a more thorough inspection, clean the coils with specialized equipment, check refrigerant levels, and ensure the system is operating at its best. In conclusion, while aluminum coils do not require any specific special maintenance, regular cleaning, inspection, and occasional coil straightening are essential to ensure their optimal performance, prevent damage, and extend their lifespan.

- Q: What are the potential applications of mill-finished aluminum coils?

- Mill-finished aluminum coils have a wide range of potential applications due to their versatile properties and finishes. Some of the potential applications of mill-finished aluminum coils include: 1. Building and construction: Mill-finished aluminum coils are commonly used in the building and construction industry for various applications. They can be used for roofing, siding, wall cladding, gutters, and downspouts, among others. The mill finish provides a clean and smooth appearance, enhancing the aesthetic appeal of the building while also offering durability and corrosion resistance. 2. Automotive industry: Mill-finished aluminum coils find applications in the automotive industry due to their lightweight nature, high strength-to-weight ratio, and corrosion resistance. They can be used for manufacturing body panels, trims, and other components, contributing to fuel efficiency and reducing the overall weight of vehicles. 3. Electrical industry: Mill-finished aluminum coils are used in the electrical industry for various applications. They can be used for manufacturing electrical enclosures, transformers, busbars, and conductors due to their electrical conductivity and corrosion resistance. The mill finish ensures a high-quality surface finish for these electrical components. 4. Packaging industry: Mill-finished aluminum coils are widely used in the packaging industry due to their excellent barrier properties and formability. They can be used for manufacturing aluminum foil, cans, lids, and other packaging materials. The mill finish provides a smooth surface, making it suitable for printing and branding purposes. 5. Household appliances: Mill-finished aluminum coils are used in the manufacturing of household appliances such as refrigerators, ovens, and air conditioners. They provide a lightweight and corrosion-resistant solution for these appliances, ensuring durability and energy efficiency. 6. Aerospace industry: Mill-finished aluminum coils find applications in the aerospace industry due to their lightweight nature and high strength. They can be used for manufacturing aircraft structures, interior components, and other parts. The mill finish provides a smooth surface, ensuring aerodynamic efficiency and reducing drag. 7. Marine industry: Mill-finished aluminum coils are widely used in the marine industry for various applications. They can be used for manufacturing boat hulls, decks, and other components due to their corrosion resistance and lightweight properties. The mill finish ensures a clean and polished appearance, enhancing the aesthetics of the vessel. Overall, mill-finished aluminum coils have numerous potential applications across various industries due to their versatile properties, including lightweight, corrosion resistance, formability, and aesthetic appeal.

- Q: Are aluminum coils suitable for thermal insulation?

- Aluminum coils, unfortunately, do not serve as suitable thermal insulation. With its high conductivity, aluminum promptly transfers heat, rendering it ineffective in impeding heat transfer between areas or maintaining desired temperatures within a given space. In order to achieve optimal thermal insulation, materials boasting low thermal conductivity, such as fiberglass, mineral wool, or foam insulation, are preferred as they effectively minimize heat transfer and offer superior insulation.

Send your message to us

Black Aluminum Coil Stock for Cans with Bright Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords