Aluminum Master Casting Coil Hot Rolled/Cold Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

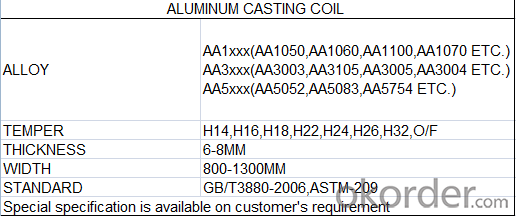

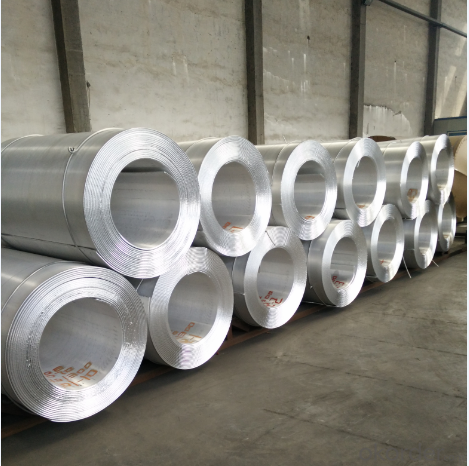

1.Structure of Aluminum Master Casting Coil Hot Rolled/Cold Rolled:

Aluminum Master Casting Coil Hot Rolled/Cold Rolled is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of Aluminum Casting Coil for thin coil is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Aluminum Master Casting Coil Hot Rolled/Cold Rolled:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Aluminum Master Casting Coil Hot Rolled/Cold Rolled

4. Production Process of Aluminum Master Casting Coil Hot Rolled/Cold Rolled

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Master Casting Coil Hot Rolled/Cold Rolled

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: What do the two items (COIL:873347 HEAT: number) on the label of the raw material of aluminum coil stand for?

- COIL means aluminum coil and HEAT means heating, so together they mean hot rolled coil.

- Q: Can aluminum coils be used in the production of aluminum composite ceilings?

- Yes, aluminum coils can be used in the production of aluminum composite ceilings. Aluminum coils are commonly used as the base material for manufacturing aluminum composite panels, which are then used in various applications including ceilings. The coils are processed and coated to meet the desired specifications and aesthetics of the composite ceiling panels.

- Q: What are the different packaging weights available for aluminum coils?

- The different packaging weights available for aluminum coils vary depending on the specific requirements and applications. Common packaging weights for aluminum coils range from 1,000 to 10,000 pounds or more. These weights can be customized to meet the needs of different industries and transportation methods.

- Q: WHERE IS ALUMINIUM FOUND, LIKE WHERE IS IT MINED FROM...10 points tell me quick

- Australia, Brazil, China, India

- Q: I heard that clay pots and aluminum cans are great caves for my fish to breed in but will the can rust???

- Aluminum okorder /

- Q: How are aluminum coils inspected for defects?

- Aluminum coils are inspected for defects through various methods to ensure their quality and performance. One common method is visual inspection, where trained inspectors carefully examine the surface of the coil for any visible defects such as scratches, dents, or other damage. This type of inspection is usually done by human inspectors using proper lighting and magnifying tools to detect even the smallest defects. In addition to visual inspection, advanced technologies such as automated optical inspection (AOI) systems are used to thoroughly inspect the coils. These systems use cameras and image processing software to detect and analyze any abnormalities on the surface of the coil. AOI systems can identify defects such as cracks, pits, or surface irregularities that may not be visible to the naked eye. Another method used to inspect aluminum coils is ultrasonic testing. This non-destructive testing technique involves sending ultrasonic waves through the coil and analyzing the echoes that bounce back. By measuring the time it takes for the ultrasonic waves to travel through the coil and the amplitude of the echoes, defects such as internal cracks, voids, or inclusions can be identified. Furthermore, eddy current testing is another commonly used method for defect inspection in aluminum coils. This technique involves passing an alternating current through a coil and measuring the changes in the electromagnetic field caused by any defects in the material. Changes in the field can indicate the presence of cracks, voids, or other anomalies. Overall, a combination of visual inspection, automated optical inspection systems, ultrasonic testing, and eddy current testing is typically employed to thoroughly inspect aluminum coils for defects. These inspection methods help ensure that the coils meet the required quality standards and are free from any defects that could impact their performance or durability.

- Q: What are the different coil winding options for aluminum coils?

- There are several coil winding options for aluminum coils, each with its own advantages and applications. 1. Layer Winding: This is the most common and simplest method, where the coil is wound in a single layer. It is cost-effective and suitable for applications where high voltage or high current is required. 2. Disc Winding: In this method, the coil is wound in a disc-like shape, with each layer stacked on top of the previous one. This winding technique allows for better heat dissipation and is often used in high-frequency applications. 3. Helical Winding: Helical winding involves winding the wire in a spiral pattern around the coil form. This method allows for a higher number of turns in a given space, resulting in increased inductance. It is commonly used in applications requiring high inductance, such as transformers and inductors. 4. Interleaved Winding: Interleaved winding is a technique where multiple layers of coil windings are interleaved, meaning one layer is wound in one direction, and the next layer is wound in the opposite direction. This method helps reduce the overall size of the coil and improves its efficiency by reducing the proximity effect. 5. Foil Winding: Foil winding involves using thin layers of aluminum foil instead of wire to create the coil. This method offers better cooling and reduces the overall size of the coil. It is commonly used in high-power applications, such as electric vehicle motors and power generators. 6. Sectional Coil Winding: In this method, the coil is divided into sections, and each section is wound separately. It allows for better control over the coil's shape and size, making it suitable for unique or irregularly shaped applications. The choice of coil winding option depends on factors such as the desired electrical characteristics, space constraints, cooling requirements, and cost considerations. It is important to carefully analyze the requirements of the specific application before selecting the appropriate coil winding technique for aluminum coils.

- Q: What is the expected lead time for manufacturing aluminum coils?

- The lead time for manufacturing aluminum coils can vary depending on several factors, such as the complexity of the coil design, the size and quantity of the coils being manufactured, the availability of raw materials, and the production capacity of the manufacturing facility. Generally, the lead time for aluminum coil manufacturing can range from a few weeks to several months. If the coils have a simple design and readily available raw materials, the lead time is usually shorter. However, if the coils have a complex design or require specialized materials, the lead time may be longer. Additionally, the production capacity of the manufacturing facility is a significant factor in determining the lead time. Facilities with higher production capacities can manufacture and deliver aluminum coils more quickly than those with lower capacities. To obtain an accurate estimate of the expected lead time, it is important to consult with the specific manufacturer. They will assess the project's specific requirements and provide a timeframe that aligns with those requirements.

- Q: What is the typical density of aluminum coils?

- The density of aluminum coils can differ depending on the particular alloy and manufacturing method employed. Generally, aluminum coils have a density of approximately 2.7 g/cm³. This value is slightly lower than pure aluminum, which has a density of 2.7-2.8 g/cm³. It should be noted that the density of aluminum coils can also be affected by factors such as coil thickness and any surface coatings or treatments applied.

- Q: How much is one ton of aluminum coil?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet.If you have any questions, please ask. I hope to help you.

Send your message to us

Aluminum Master Casting Coil Hot Rolled/Cold Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords