Aluminum Master Cast Coil for Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Master Cast Coil for Manufacturer:

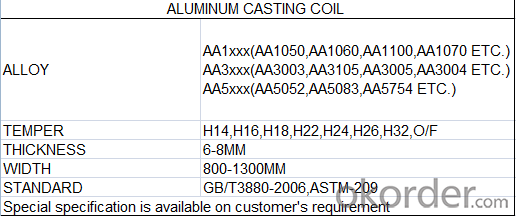

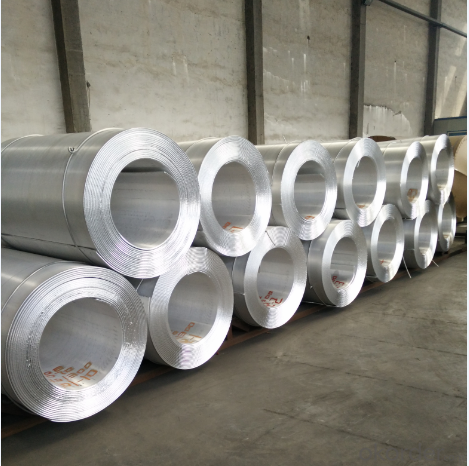

Aluminum Master Cast Coil for Manufacturer is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of Aluminum Casting Coil for thin coil is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Aluminum Master Cast Coil for Manufacturer:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Aluminum Master Cast Coil for Manufacturer

4. Production Process of Aluminum Casting Coil for thin coil and sheet

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Master Cast Coil for Manufacturer

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q:How do aluminum coils compare to other metals in terms of strength?

- Aluminum coils have excellent strength-to-weight ratio compared to many other metals. While aluminum is not as strong as steel, it is lighter and more flexible, making it a popular choice in various applications. Aluminum coils can withstand significant forces without breaking or deforming, making them suitable for a wide range of industries, including automotive, aerospace, and construction. Additionally, aluminum coils have good corrosion resistance, which further enhances their durability and longevity. However, it is important to note that the strength of aluminum can vary depending on the alloy and temper used, so specific comparisons should be made based on the particular application and requirements.

- Q:Are aluminum coils suitable for air conditioning systems?

- Air conditioning systems can utilize aluminum coils, which are commonly employed due to their numerous advantages. Firstly, aluminum, being a lightweight material, facilitates ease of handling and transportation during installation. Additionally, this lightweight characteristic reduces the unit's overall weight, rendering it more energy-efficient. Moreover, aluminum coils possess exceptional heat transfer properties, thereby enabling efficient air cooling. They exhibit enhanced thermal conductivity, facilitating rapid and effective heat transfer. Consequently, this leads to improved cooling performance and enhanced energy efficiency, resulting in reduced electricity consumption and long-term cost savings. Furthermore, aluminum coils surpass other materials, such as copper, in terms of superior corrosion resistance. Given the exposure of air conditioning systems to moisture and humidity, this resistance is crucial. Aluminum coils can withstand these conditions without corroding or deteriorating, ensuring a longer lifespan and reliable performance. Another advantage of aluminum coils lies in their affordability. Aluminum is a cost-effective material, making it a favored choice among air conditioning manufacturers. This affordability subsequently translates into lower costs for consumers, making air conditioning systems more accessible and economically viable. In conclusion, the suitability of aluminum coils for air conditioning systems is evident due to their lightweight nature, impressive heat transfer properties, corrosion resistance, and affordability. They offer efficient cooling capabilities, durability, and cost-effectiveness, establishing themselves as the preferred choice for air conditioning units.

- Q:How are aluminum coils protected during shipping?

- Aluminum coils are typically protected during shipping by being wrapped in a layer of protective film or paper, secured with strapping or bands, and then placed on pallets or in crates. Additionally, they may be enclosed in metal or wooden containers to provide further protection against external damage during transit.

- Q:What is the common color of aluminum coil membrane?

- The blue transparent membrane is the most common.

- Q:How do aluminum coils compare to plastic coils in terms of durability?

- Aluminum coils are generally more durable than plastic coils. They are resistant to corrosion and can withstand high temperatures, making them suitable for various applications. Plastic coils, on the other hand, are more prone to wear and tear, especially in harsh environments or with heavy usage. While both types have their own advantages, aluminum coils are generally considered to be more durable in the long run.

- Q:How are aluminum coils protected against moisture?

- To safeguard aluminum coils against moisture, a process known as coating is employed. A shielding layer of protective material, such as polymer or paint, is applied to the coils, creating a barrier between the aluminum and its surroundings. This coating effectively obstructs direct contact between moisture and the aluminum surface, mitigating the chances of corrosion and harm. Moreover, certain manufacturers may choose to augment moisture resistance by applying a specialized sealant on the coil edges. Through these protective measures, the durability of aluminum coils is maintained, enabling them to function optimally even in environments characterized by humidity or dampness.

- Q:What happened to the aluminum coil coming out of the annealing furnace?

- There is oil on the aluminum coil and the annealing time is too long.

- Q:How much is the 25mm aluminum coil at current market?

- You must mean 25-wide aluminum coil. The price consists of the aluminum ingot price and processing charges. For example, if the processing price is 4500 yuan, it is relatively cheap. 25mm-wide aluminum coil is very narrow, so it will be much complicated to strip.

- Q:What is the typical coefficient of thermal expansion for aluminum coils?

- The typical coefficient of thermal expansion for aluminum coils is around 23.6 x 10^-6 per degree Celsius.

- Q:What are the surface treatment options for aluminum coils?

- There are several surface treatment options available for aluminum coils, depending on the specific requirements and desired outcomes. Some common options include: 1. Anodizing: This is a widely used treatment method that involves creating a protective oxide layer on the surface of the aluminum coil. Anodizing provides corrosion resistance, improves durability, and allows for color customization through dyes. 2. Painting: Aluminum coils can be coated with various types of paint to enhance their appearance, provide additional protection against corrosion, and improve resistance to UV radiation. Both liquid and powder coatings are available, with different finishes and levels of durability. 3. Coil coating: This is a continuous process where a coating material is applied to the aluminum coil's surface. The coil is then cured, resulting in a uniform and durable coating. This treatment option offers a wide range of finishes, colors, and special effects. 4. Laminating: By applying a protective film or sheet onto the surface of the aluminum coil, laminating can enhance its resistance to scratches, abrasion, and chemicals. This treatment is often used in applications where the coil may come into contact with harsh environments. 5. Brushing or polishing: These mechanical treatments can give the aluminum coil a desired texture, such as a brushed or mirror-like finish. Brushing creates a pattern of parallel lines, while polishing results in a highly reflective, smooth surface. 6. Chemical conversion coatings: These coatings are typically applied as a pre-treatment before painting or as a standalone treatment. They enhance corrosion resistance and provide a base for subsequent coatings, such as paint or powder coating. These are just a few examples of the surface treatment options available for aluminum coils. The choice of treatment will depend on factors such as the desired appearance, level of corrosion resistance, durability, and the specific application requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Master Cast Coil for Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords