Coated and Stucco Embossed Aluminium Coils for Refrigerator

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

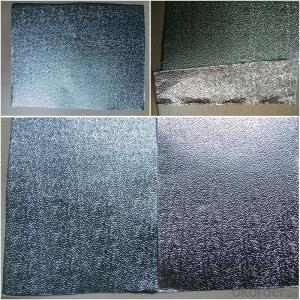

1.Structure of Coated and Stucco Embossed Aluminium Coils for Refrigerator

Our coated and stucco embossed aluminium coils are widely used in regrigerators, ice-boxes, cold storage, freezer, etc.

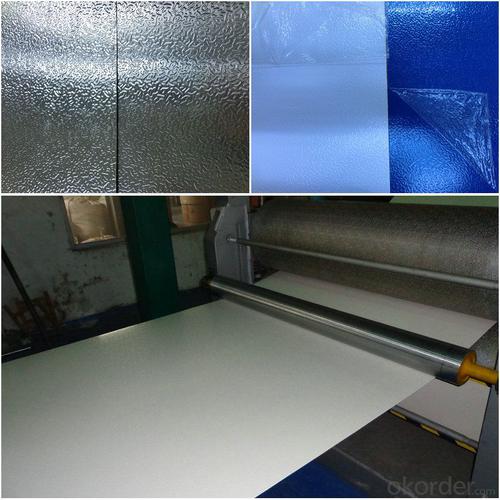

We normally use 3105, H44 as base coils. Specification of our stucco embossed and color coated aluminium coils: thickness 0.2-0.6mm, width less than 1600mm. As for coating, we normally use PVDF coating, PE coating, etc. We can adjust coating as per customers’ requirements.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of Coated and Stucco Embossed Aluminium Coils for Refrigerator

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

3. Coated and Stucco Embossed Aluminium Coils for Refrigerator Images

4. Specification of Coated and Stucco Embossed Aluminium Coils for Refrigerator

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

Is Aluminium Foil Safe to Use?

It just seems like yesterday when I was a little girl and my mom would pack a parantha in a tea towel and send it with me to my school for lunch. I loved the way the lunch was packed which never spilled a drop of oil and never messed my school bag. The years saw a new trend approaching. The tea towels were replaced by Aluminum Foil, as it was believed to keep the food warm, fresh and avert any spillage. Of course, we as a kid loved it, not that it mattered to us but we could crush the aluminum foil into a ball after finishing our lunch and play recklessly at the break. Unfortunately playing with it was the only legitimate and safe use of Aluminum foil. Now when I look back I realize how limited was our knowledge. We were unaware as to how unsafe it is to wrap the food with aluminum foil especially when it is hot.

A study showed that increasing level of aluminum in our food and life leads to brain and bone damage. The scary truth about aluminum is that it is found in so many things in our world and it is toxic to our bodies, even in small amounts. From household products to vaccinations, aluminum pervades our lifestyle, and if not monitored closely, can easily make its way into our bodies causing lasting, harmful effects. The researchers found dangerously high levels of aluminum in foods after being cooked, reheated, and even cooked in aluminum foil. If food is cooked on high temperature wrapped in the aluminum foil the aluminum leaches into your food and then in turn in your body. The cause for alarm is that when aluminum accumulates in the body, it can lead to osteoporosis and Alzheimer's.

Now over the passage of years when I have become a mother myself I want to see my kid grow up safe in the healthy environment. Although I cannot eliminate aluminum out of our lives completely but I can determine how to avoid it to the maximum. Then the question arises are there any viable substitutes for aluminum? What is that we can do to protect our food from getting toxic? These are some of the practices if followed can make our food stay safe.

Never cook, heat up, or place hot food on aluminum foil. You can use tempered glass containers to do that or more economic would be to use food wrapping paper or parchment paper instead.

Avoid storing tomatoes, citrus fruits, or spices in foil. As mentioned above food wrapping paper keeps the wrapped food fresh and doesn't contaminate it.

Never use aluminum pots or cooking utensils. Instead, invest in stainless steel pots and pans. You can even use seasoned cast iron skillets or pots or even stoneware as a substitute to aluminum pans.

Banana leaves have been considered as the most healthy and natural way of storing, cooking and reheating food. If you can easily find it in your vicinity it can be the best substitute of aluminum foil.

While baking use of aluminum foil can be avoided if you line your baking sheet with parchment paper to bake your cookies or even roast your veggies and poultry.

If you need to cover your food while or after baking then again parchment paper is the answer, it doesn't let your food become dry and saves it from splashing all over the oven.

I can't undo my past but I know for sure that the future of my family lies in my hands. I can pretend to be ignorant or simply callous but ultimately the loss is mine. It's better we adopt healthy and safe food practices like eliminating the use of aluminum foil from our lives and embracing ways like use of banana leaves or food wrapping paper. Don't wait, start today!

- Q: What are some common types of aluminum coils used in various industrial applications?

- <p>Yes, there are several types of aluminum coils commonly used in industry. These include: 1) Plain aluminum coils, which are used in packaging and construction. 2) Embossed aluminum coils, utilized for decorative purposes and in the automotive industry. 3) Painted aluminum coils, often used in building materials and appliances. 4) Galvanized aluminum coils, which are corrosion-resistant and used in exterior applications. 5) Heat-treated aluminum coils, known for their strength and used in aerospace and automotive parts. Each type serves specific purposes based on the properties of the aluminum and the coatings or treatments applied.</p>

- Q: Are there any limitations on the width-to-thickness ratio of aluminum coils?

- Yes, there are limitations on the width-to-thickness ratio of aluminum coils. The specific limitations depend on various factors such as the intended application, manufacturing process, and the mechanical properties of the aluminum alloy being used. Generally, a higher width-to-thickness ratio can result in increased material instability, difficulty in handling, and potential quality issues. Therefore, it is necessary to carefully consider these factors and consult industry standards and guidelines to determine the appropriate width-to-thickness ratio for aluminum coils.

- Q: What role does the powdered aluminum play in this reaction?

- Aluminum is what burns or combines with oxygen. Learn How, you have it backwards. Iron oxide is the oxidizer.

- Q: This question asks for the method to cut an aluminum coil into smaller sections.

- <p>To cut an aluminum coil into smaller pieces, you can use a metal cutting band saw, which is designed for cutting metal materials. Ensure the blade is sharp and the speed is appropriate for aluminum. Secure the coil in a vice or a cutting table to prevent movement during cutting. Wear safety goggles and gloves. Turn on the saw and slowly feed the coil through the blade, applying steady pressure. After cutting, smooth any rough edges with a file or sandpaper. Always follow safety precautions and manufacturer's instructions for your specific cutting tool.</p>

- Q: Is it safe and effective to heat an aluminum coil using a microwave oven?

- <p>No, you should not use a microwave to heat an aluminum coil. Microwaves can cause aluminum to heat unevenly and potentially spark, which is dangerous. Aluminum is a good conductor of electricity and can reflect microwaves, leading to arcing and fire hazards. Always use microwave-safe materials when heating food or other substances in a microwave.</p>

- Q: How are aluminum coils used in the production of HVAC components?

- Aluminum coils play a crucial role in the production of HVAC (Heating, Ventilation, and Air Conditioning) components. These coils are used in the heat transfer process of HVAC systems, where they assist in both heating and cooling applications. In HVAC systems, aluminum coils are typically employed in air conditioning units and heat pumps. They are an integral part of the refrigeration cycle, which allows for the transfer of heat from one area to another. The coils serve as the key component in the heat exchanger, responsible for absorbing heat from the indoor air during cooling or releasing heat into the indoor air during heating. The process starts with the refrigerant, a substance that circulates through the coils, absorbing and releasing heat. When the HVAC system is in cooling mode, the aluminum coils act as an evaporator. The warm air from the indoor space passes over the coils, and the refrigerant within the coils absorbs the heat, cooling down the air. This cooled air is then circulated back into the room, providing a comfortable environment. On the other hand, during heating mode, the aluminum coils operate as a condenser. The refrigerant, which has absorbed heat from the outside environment, passes through the coils. The cooler air from the indoor space flows over the coils, causing the refrigerant to release its heat. This heat is then distributed throughout the room, ensuring a warm and cozy atmosphere. The use of aluminum coils in HVAC systems offers several advantages. Aluminum is lightweight, which makes the HVAC units more portable and easier to install. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat transfer. This results in improved energy efficiency and reduced operating costs of the HVAC system. Moreover, aluminum coils are highly resistant to corrosion, ensuring their durability and longevity. They can withstand harsh environmental conditions, such as humidity and exposure to chemicals, without deteriorating. This makes aluminum coils a reliable and cost-effective choice for HVAC manufacturers. In conclusion, aluminum coils are essential components in the production of HVAC systems. They facilitate the heat transfer process, enabling efficient cooling and heating functions. With their lightweight nature, excellent thermal conductivity, and corrosion resistance, aluminum coils contribute to the overall performance, energy efficiency, and durability of HVAC units.

- Q: Its currently 3 AM so i can't check, but my question is:does aluminum rust slower/faster than other metals? I've basically had this bike for about 6 years, but only rid it once. Its been sitting in my backyard under a roof (safe from rain) for 6+ years. Is it safe to ride it? Also, bonus question: Does having a bike on campus make life 10x easier?

- Simple all alloy including aluminium turns to talcum powder which left will go black this is when the metal is oxidising. If the black is visible then scrap anything with it on. Have rescued many old bikes so things such as cables, tyres, tubes and your chain should be replaced as these usually suffer, if you are lucky these might still work. The chain will often freeze into a memory so won't turn, if not oiled may need hacksawed off. Most old bikes will reawaken with a few new or old replacement parts, also if will start to loosen with use so check it plus the bike will be desperately dry so to avoid component failure throw as much lubricant at it till it runs out and rejects it. The bike should only be sleeping so once wakened and sorted it will be as safe as you left it, though do check your brake blocks as these can split and perish. Steel parts can be replaced with alloy or treated with Kurust which gives rust a modern black component look. Have just woken a twenty five year old bike, once rebuilt it runs like a new bike plus is now safe as it has had various items modernised, something recommended for older bikes.

- Q: The user is asking if it's safe to use aluminum coil for food preparation in a microwave oven.

- <p>No, you should not use aluminum coil for food preparation in a microwave oven. Aluminum is a metal and can cause sparks or even a fire when exposed to the microwave's electromagnetic field. It can also reflect microwaves, potentially damaging the oven. Always use microwave-safe materials such as glass, ceramic, or microwave-safe plastic containers for food preparation in a microwave.</p>

- Q: What are the common fabrication techniques used for aluminum coils?

- Aluminum coils undergo various fabrication techniques to achieve desired properties. Rolling, annealing, slitting, and coating are commonly employed. Rolling, a primary technique, reduces thickness and shapes aluminum by passing it through rollers. Hot rolling, with high temperatures, makes the metal more malleable, while cold rolling is done at room temperature. Annealing, another important technique, enhances mechanical properties by heating and slowly cooling the aluminum. It relieves stresses, improves formability, and strengthens the metal. Slitting cuts wide coils into narrower strips, providing customization options. Specialized machines are used for precise width adjustments. Coating, a common technique, improves durability, corrosion resistance, and appearance. Paint, anodizing, or powder coating methods create protective layers, preventing oxidation and enhancing weather resistance and aesthetics. These techniques are widely used in the aluminum industry, producing high-quality coils for construction, automotive, aerospace, electrical, and other industries.

- Q: Is it possible to use a welding torch for joining steel coils?

- <p>Yes, you can use a welding torch to weld steel coils together. However, it's important to choose the right type of welding process suitable for the specific steel grade and the desired strength of the joint. Common methods include gas metal arc welding (GMAW), shielded metal arc welding (SMAW), and flux-cored arc welding (FCAW). Ensure you follow safety protocols, use appropriate protective gear, and have a good understanding of the welding process to achieve strong, reliable welds.</p>

Send your message to us

Coated and Stucco Embossed Aluminium Coils for Refrigerator

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords