Bronze Anodized 3000 Series Stucco Embossed Aluminum Coils for Refrigerator

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Specifications of 3000 Series Stucco Embossed Aluminum Coils for Refrigater

Alloy:1060 1050 1100 1200 3003

Temper: O H12 H14 H16 H18 H24

Thickness(mm):0.2-10mm

Width(mm):30-2300

Length(mm):800-13000

Packing: wooden/veneer pallet, wooden/veneer case

Unit Price/Payment: FOB, CIF, CFR

Payment term: TT, LC

MOQ: 2.0-2.5 metric ton per size

2. Application of 3000 Series Stucco Embossed Aluminum Coils for Refrigater

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of 3000 Series Stucco Embossed Aluminum Coils for Refrigater

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

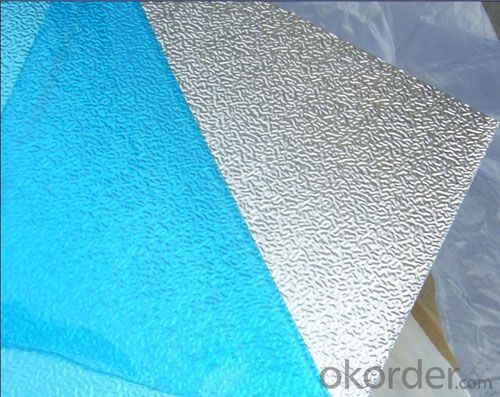

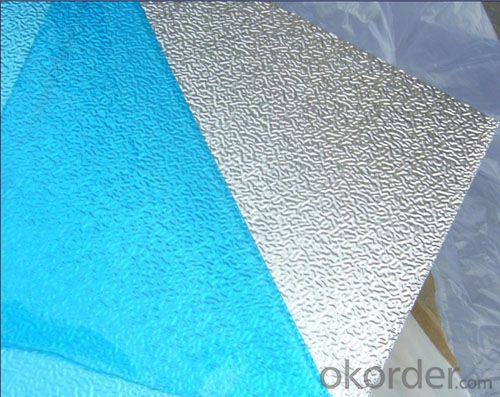

5. Image of 3000 Series Stucco Embossed Aluminum Coils for Refrigater

6. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q: Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be and are commonly used in food packaging. Aluminum is a popular choice for food packaging due to its excellent barrier properties, which protect the food from light, oxygen, moisture, and other external factors that can spoil or contaminate it. Aluminum sheets are lightweight, durable, and resistant to corrosion, making them suitable for various types of food packaging, such as foil wraps, containers, trays, and pouches. Additionally, aluminum is a recyclable material, making it an environmentally friendly choice for food packaging.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets can be suitable for electrical bus bars in certain applications. Aluminum has several properties that make it a viable option for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in applications where weight reduction is important. Additionally, aluminum has good electrical conductivity, although it is not as conductive as copper. However, aluminum bus bars can still handle high electrical currents and are commonly used in power distribution systems. One downside of aluminum bus bars is that they have a higher resistance compared to copper bus bars. This means that they can generate more heat, especially under high current loads. To mitigate this issue, aluminum bus bars are often designed with larger cross-sectional areas to reduce resistance and dissipate heat more effectively. Another challenge with aluminum bus bars is their susceptibility to oxidation and corrosion. This can be addressed by applying protective coatings or using alloys with better corrosion resistance. It is also important to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In summary, aluminum sheets can be suitable for electrical bus bars, especially in applications where weight reduction is important. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

- Q: What are the advantages of using aluminum sheets in the packaging industry?

- Aluminum sheets have numerous benefits in the packaging industry. To begin with, their lightweight composition makes them ideal for packaging purposes. Unlike steel or glass, aluminum is much lighter, making it easier to handle and transport. This weight advantage also reduces shipping costs, as less fuel is needed for transportation. In addition, aluminum sheets provide excellent barrier properties. They effectively block out oxygen, moisture, and light, all of which can compromise the quality and freshness of packaged goods. This barrier extends the shelf life of products, ensuring they reach consumers in optimal condition. Moreover, aluminum sheets are highly durable and resistant to corrosion. This durability guarantees that packaged items remain protected, even in challenging environmental conditions. They are also resistant to temperature fluctuations, maintaining the integrity of the packaging material without warping or deforming. Furthermore, aluminum is a highly recyclable material. Its use in the packaging industry promotes sustainability and reduces the carbon footprint. Aluminum packaging is easily recyclable and reusable, minimizing the need for new materials and reducing waste. Additionally, aluminum sheets offer versatility in terms of design and customization. They can be easily molded and shaped into various packaging formats, including cans, trays, foils, and pouches. This flexibility enables packaging manufacturers to create innovative and visually appealing solutions that cater to the unique needs and preferences of different industries and consumers. Overall, the advantages of using aluminum sheets in the packaging industry encompass their lightweight nature, excellent barrier properties, durability, recyclability, and versatility. These benefits establish aluminum sheets as the preferred choice for packaging manufacturers, ensuring the protection, preservation, and attractiveness of packaged products.

- Q: Can the aluminum sheets be used for manufacturing ventilation systems?

- Yes, aluminum sheets can be used for manufacturing ventilation systems. Aluminum is a lightweight and corrosion-resistant material, making it a suitable choice for ventilation systems. Its high thermal conductivity allows for efficient heat transfer, making it ideal for applications where temperature control is necessary. Additionally, aluminum is easily formable, allowing for the creation of complex shapes and designs required for ventilation systems. Overall, aluminum sheets are a popular and practical choice for manufacturing ventilation systems.

- Q: What are aluminum sheets made of?

- Aluminum sheets are typically made of pure aluminum or aluminum alloy, which is a combination of aluminum and other elements such as copper, magnesium, or zinc. The exact composition of the alloy depends on the specific application and desired properties of the sheet. Pure aluminum sheets are softer and more malleable, while alloyed aluminum sheets offer increased strength, durability, and resistance to corrosion. The sheets are produced through a process called rolling, where a large block or ingot of aluminum is passed through a series of rollers to reduce its thickness and create the desired sheet size.

- Q: just bought a hobart handler 140 (already love it), and was just wondering on what gas to use for aluminum. my welder will be set up for mild steel (75% argon 25% CO2). it would be nice to be able to use this mix with aluminum as well, as it would be easy to just switch spools of wire, but the manual says to use a 100% argon mix when welding with aluminum. will the 25% CO2 make a difference welding aluminum?

- I can't find a reference, but I think aluminum may react with CO2. Aluminum is produced by reacting aluminum oxide with carbon when electrical energy is injected, so I guess that the reaction may go backwards and produce energy

- Q: Are aluminum sheets suitable for reflective signage?

- Indeed, reflective signage can effectively utilize aluminum sheets. This adaptable material is frequently employed for such signs because of its resilience, lightness, and capacity to reflect light. With a noteworthy reflectivity index, aluminum proves itself ideal for situations where visibility is of utmost importance, such as road signs, traffic signs, and safety signs. By applying reflective films or paints to aluminum sheets, their reflective properties can be further enhanced, guaranteeing optimal visibility even in dimly lit environments. Furthermore, aluminum's resistance to weathering, corrosion, and fading ensures that it remains a durable and economical option for reflective signage in the long run.

- Q: Can aluminum sheets be used for pharmaceutical cleanrooms?

- Yes, aluminum sheets can be used for pharmaceutical cleanrooms. Aluminum is a popular choice for cleanroom construction due to its excellent durability, corrosion resistance, and ease of cleaning. It is also non-porous, which helps prevent the growth of bacteria and ensures a sterile environment. Additionally, aluminum sheets can be easily fabricated and installed, making them a suitable material for pharmaceutical cleanroom applications.

- Q: I put the aluminum in copper chloride for an experiment and i was wondering if they had different properites.

- Yes, Rust is an Oxide of iron which can be broken down chemically into simpler substances. Aluminium is a pure Element which cannot be broken down chemically or physically into other substances.

- Q: Are aluminum sheets suitable for solar panel applications?

- Indeed, aluminum sheets prove to be a fitting choice for incorporating into solar panel applications. Due to its lightweight and durable characteristics, aluminum emerges as an optimal substance for fabricating solar panel frames. Its ability to resist corrosion guarantees the panels' ability to endure external elements and maintain longevity. Moreover, aluminum's impressive thermal conductivity aids in effectively dispersing generated heat, a favorable attribute for solar panels during operation. Furthermore, aluminum's recyclability further aligns with the eco-friendly aspects of solar energy. All in all, aluminum sheets stand as a dependable and pragmatic selection for implementing in solar panel applications.

Send your message to us

Bronze Anodized 3000 Series Stucco Embossed Aluminum Coils for Refrigerator

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords