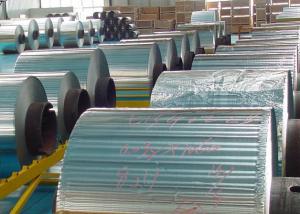

8011 Painted Aluminum Trailer Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of 8011 Aluminium Coils

|

Alloy |

AA8011 |

|

Temper: |

H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

|

Thickness: |

0.10-500mm |

|

Width: |

10mm- 2200mm |

|

Standard: |

GB/T3880-2006, ASTM, ISO, EU standard |

|

Special Specification is available on customer’s requirement | |

2. Applications of 8011 Aluminium Coils

8011 Aluminium Coils are widely used in househould field, package, cookware, construction, decoration, etc.

3. Package & Delivery of 8011 Aluminium Coils

Seaworthy package, water-proof paper wrapped inside, carton wrapped outside in wooden pallets by 20FCL or 40GP.

4. Production Flow of 8011 Aluminium Coils

The main producingprocedure includes the following steps:

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

- Q: Im wondering as to how i darken the slide and frame of an airsoft 1911 pistol. I polished off all the black paint and exposed the chromish aluminum. I have some ideas to darken the metal but not sure. Maybe using olive oil and heating it up but im afraid i might warp the metal. I want it to come out sort of like a greyish gunmetal. Anybody know of a good process to give that worn out war like effect to the gun without painting it?

- Use gun bluing . It is the stuff they use on steel guns, it is kind of a dye. Got at a sports store that sells real guns.

- Q: the amp setting when welding aluminum tig? and what color should the electrode feeder be bronze or chrome grey? u know the one u use with your hands

- Best electrodes to use for Aluminum welding is 1.5% lanthanum oxide (gold color code.). 2% zirconia (brown) or 2% thorium oxide (red) can also be used. Note that zirconia-doped electrodes should never be used for DC welding. A lot of welders like to quote offhand the rule 1 amp for every 0.001 inch of thickness. This applies to steel, stainless, and nickel alloys only. Due to the lower melting point, lower specific heat capacity, and higher thermal conductivity of of Al, this rule should NOT be used for Al! I recommend welding a test piece first with the same joint configuration and thickness of the part you intend to weld. Note that fillet welds require more current than butt welds or edge welds. Start out by using 2/3 amp per 0.001 of thickness, in other words, reduce the current of the above rule by about 30-40% . Make 3 test weld, then check to see if there's any visible penetration on the other side. If you don't see any through-pentration at all, increase the current by about 10-20 amps and test again.

- Q: Are the aluminum sheets suitable for manufacturing electronics components?

- Yes, aluminum sheets are suitable for manufacturing electronics components. Aluminum is a lightweight, durable, and cost-effective material that is widely used in the electronics industry. It has excellent electrical conductivity, which is essential for the proper functioning of electronic devices. Aluminum sheets can be easily shaped, cut, and formed into various components such as heat sinks, enclosures, and connectors. Additionally, aluminum has good thermal conductivity, allowing it to effectively dissipate heat generated by electronic components. This makes aluminum sheets an ideal choice for manufacturing electronics components.

- Q: What are the different forming techniques for aluminum sheets?

- Some of the different forming techniques for aluminum sheets include bending, stretching, deep drawing, roll forming, and hydroforming.

- Q: Can aluminum sheets be used in the aerospace industry?

- Indeed, the aerospace industry does employ aluminum sheets. Aluminum, being a lightweight material with a remarkable strength-to-weight ratio, is highly favored for numerous aerospace purposes. Its usage is prevalent in the manufacturing of aircraft structures, including fuselages, wings, and panels. The adoption of aluminum sheets in the aerospace sector offers several advantages, encompassing diminished fuel consumption due to weight reduction, enhanced maneuverability, and heightened payload capacity. Furthermore, aluminum showcases excellent resistance to corrosion, a vital trait for aircraft operating in harsh environmental conditions. All in all, the aerospace industry extensively relies on aluminum sheets, owing to their advantageous properties and exceptional performance.

- Q: What are the different surface finishes for aluminum sheets in the automotive industry?

- The different surface finishes for aluminum sheets in the automotive industry include mill finish, anodized finish, and painted finish. Mill finish refers to the untreated surface of aluminum sheets, which typically has a matte appearance. Anodized finish involves an electrochemical process that creates a protective layer on the surface of aluminum, enhancing its resistance to corrosion and increasing its durability. Painted finish involves applying a layer of paint onto the aluminum sheet, providing both aesthetic appeal and additional protection against the elements.

- Q: Hi,I'm building a tricycle for 2 passengers as well as the rider.My main concern for the structure of the chassis is the junction between the rear and the bike frame. Both structures on their own withstand the weight when made out of aluminium, no need to go for steel. But what about that junction? Will aluminium have a propensity to buckle? should i used double tubing or a fork design? I suppose the shape and caliber of the tube also comes into play.Lastly, which of a tube or cylindrical rod is stronger?ThanksAddendum: I'm looking at aluminium because it's cheaper and for weight reduction in the vehicle.

- You cannot weld steel to aluminum with traditional arc welding techniques. It can only be done with explosion or friction welding. I doubt either of these processes will be utilized on a trike frame as they would be cost prohibitive for low production runs. Are you an experienced aluminum welder, or will you be using one? If not, I'd suggest using steel tubing. Steel is much more forgiving during the welding process. It is stronger too; although on the downside, it is heavier. As for your design, it is very difficult to follow your description without a picture. I would be remiss to suggest something with my current, limited understanding. As far as tubing and solid rod are concerned, for the same weight, the tubing will be stronger because it has its mass located away from the center. This will give it much more structural rigidity to resist bending. Now solid rod of the same diameter is stronger than tube, but very heavy. I would think you should be able to use tubing for everything. Maybe thicker or even larger tubes for the areas of high stress concentration such as the area you ask about. If you go with the aluminum, good luck welding it. While it certainly can be done, it takes a great deal more experienced of a welder to perform this operation successfully.

- Q: What is the lifespan of the aluminum sheets?

- The lifespan of aluminum sheets can vary depending on various factors such as the quality of the material, the environment they are exposed to, and the maintenance they receive. However, with proper care and maintenance, aluminum sheets can last for several decades.

- Q: Are aluminum sheets suitable for electronics applications?

- Yes, aluminum sheets are suitable for electronics applications. Aluminum is lightweight, highly conductive, and has good thermal properties, making it an ideal material for various electronic components such as heat sinks, enclosures, and printed circuit boards. Additionally, aluminum is corrosion-resistant and cost-effective, making it a popular choice in the electronics industry.

- Q: Is it possible for an individual to install their own aluminum sheet roofing?

- <p>Yes, you can install your own aluminum sheets roof, but it requires some skills and knowledge. You'll need to measure and cut the sheets accurately, secure them properly, and ensure watertight installation. It's advisable to have experience in roofing or construction, or to follow detailed instructions and safety precautions. For complex roofs or if you're unsure, hiring a professional is recommended to avoid damage or injury.</p>

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2002 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

8011 Painted Aluminum Trailer Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords