Clear Anodized Aluminum Sheet

Clear Anodized Aluminum Sheet Related Searches

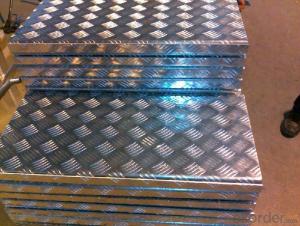

Aluminum Hot Plate 1/4 Diamond Plate Aluminum Sheet Aluminum Tread Plate Sheet Metal 4x8 Sheet Diamond Plate Aluminum Diamond Plate Sheet Aluminum Sheet Diamond Plate Aluminum Aluminum Tread Plate Sheet 4x8 Aluminum Checker Plate Sheet Anodized Aluminum Coil Stock Clear Anodized Aluminum SheetHot Searches

China Anodized Aluminum Plate Aluminum Plate China Aluminum Plate Price Home Depot Aluminum Plate Anodized Aluminum Coil Suppliers Aluminum Plate Factory Aluminum Plate Wholesale Wholesale Aluminum Plate Aluminum Plate Supplier Aluminum Plate Supply Aluminum Plate Sales Aluminum Plate Prices Aluminum Plate Sizes Aluminum Plate Manufacturers 7075 Aluminum Plate Suppliers Aluminum Armor Plate Suppliers Aluminum Tooling Plate Suppliers 5086 Aluminum Plate Suppliers 5454 Aluminum Plate Suppliers Aluminum Plate SuppliersClear Anodized Aluminum Sheet Supplier & Manufacturer from China

Okorder.com is a professional Clear Anodized Aluminum Sheet supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Clear Anodized Aluminum Sheet firm in China.Hot Products

FAQ

- 1100 scope of application of aluminum plate

- 1100 aluminum plate is generally used in utensils, heat sink, caps, printing plates, building materials, heat exchanger components, but also can be used as deep stamping products. It is widely used in various fields ranging from cooking utensils to industrial equipment

- Certainly, painting aluminum sheet is possible. However, it is crucial to adequately prepare the surface beforehand to guarantee strong paint adhesion and long-lasting results. Typically, this involves thoroughly cleaning the aluminum sheet to eliminate any dirt, grease, or oxidation. Subsequently, a primer is applied to enhance adhesion. Once the primer has dried, you can proceed with applying your desired paint. For optimal outcomes, it is recommended to select a high-quality paint suitable for metal surfaces. Moreover, if the aluminum sheet will be exposed to outdoor conditions, it is advisable to utilize a paint specifically designed for exterior use. This will ensure protection against weathering and corrosion.

- Due to their unique properties and versatility, aluminum sheets find a wide range of uses. In the construction industry, they are commonly employed for roofing, siding, and cladding, thanks to their lightweight nature, corrosion resistance, and durability. These qualities make them ideal for such purposes. In the transportation industry, aluminum sheets are widely utilized in the manufacturing of automobiles, trains, and aircraft due to their high strength-to-weight ratio. They also serve as a lightweight yet sturdy solution for trailers, truck bodies, and shipping containers. Another significant application of aluminum sheets lies in the manufacturing of consumer products. They are used to make household appliances, cookware, and electronics, as they possess excellent thermal conductivity and resistance to rust and corrosion. Additionally, their ability to withstand various weather conditions makes them suitable for the production of signage, billboards, and displays. In the packaging industry, aluminum sheets play a crucial role in the production of cans, foils, and lids. Their impermeability to light, moisture, and oxygen helps preserve the freshness and quality of food and beverages. Moreover, aluminum sheets have various industrial applications. They are utilized in the fabrication of industrial machinery, equipment, and tools due to their excellent machinability and strength. Additionally, their thermal and electrical conductivity makes them suitable for the production of heat exchangers, solar panels, and electrical conductors. In summary, aluminum sheets find application in construction, transportation, consumer products, packaging, and various industrial sectors, owing to their lightweight, corrosion resistance, durability, thermal conductivity, and electrical conductivity.

- Yes, aluminum sheets can be used for structural purposes. Aluminum is a lightweight and highly malleable material that can be easily fabricated into various shapes and sizes. It has excellent strength-to-weight ratio, making it suitable for structural applications where weight reduction is a priority. Aluminum sheets are commonly used in industries such as aerospace, automotive, and construction for making structural components like panels, beams, and frames. Additionally, aluminum has good corrosion resistance, which further enhances its suitability for structural purposes, especially in outdoor or marine environments. Overall, aluminum sheets offer a reliable and cost-effective solution for structural applications.

- What does 3003-O aluminum mean?

- There are four basic states of aluminum alloys:F--Free the condition of a product after a normal working procedure requires no special heat treatment or hardening, and the mechanical properties are not limited.

- project on aluminum and i cant think of a good/funny slogan for it! HELP! i have already seen the other possibilities on google, try to be unique, and creative! but if you cant just answer the flipping question PLZ!

- Once worth more than Gold Aluminum: It's the flipping answer If government could read your thoughts, you can always wear aluminum head gear. Aluminum - The super wealthy recycle it. Lucky Element 13 - Aluminum Say no to radiation from machines; Say yes to Aluminum Nothing Says Christmas like Shinny Metallic Reynolds Gift Wrapping Aluminum - it's worth more money than slogans because I get those for free over the Internet

- Yes, aluminum sheets are suitable for architectural louvers. Aluminum is a popular material choice for louvers due to its various advantageous properties. Firstly, aluminum is lightweight yet strong, making it an ideal material for architectural louvers. It can withstand external forces such as wind and weather conditions without compromising its structural integrity. This is crucial for louvers, as they need to provide ventilation and airflow while also maintaining their shape and functionality. Secondly, aluminum is highly resistant to corrosion and rust. Louvers are often exposed to outdoor elements, including rain, moisture, and sunlight. Aluminum's resistance to corrosion ensures that the louvers will remain durable and long-lasting, even in harsh environmental conditions. Additionally, aluminum is a versatile material that can be easily customized and fabricated into various shapes and sizes. This allows architects and designers to create louvers with unique designs and configurations to suit specific building requirements. Aluminum louvers can be tailored to provide optimal airflow, light control, and aesthetic appeal. Moreover, aluminum is a sustainable and environmentally friendly material. It is widely recyclable, meaning that aluminum louvers can be easily repurposed or reused at the end of their life cycle. Choosing aluminum for architectural louvers aligns with sustainable building practices and contributes to reducing the overall environmental impact. In conclusion, aluminum sheets are indeed suitable for architectural louvers. Their lightweight, strong, corrosion-resistant, and customizable properties make them an excellent choice for louvers in terms of functionality, durability, and aesthetics.

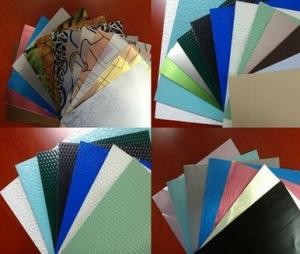

- Different finishes can be achieved when anodizing aluminum sheets. Anodizing, an electrochemical process, enhances the natural oxide layer on aluminum, increasing its thickness and durability. It is possible to customize this process to achieve clear, colored, or textured surfaces. The finish type relies on factors such as alloy composition, anodizing technique, and desired appearance. Due to their corrosion resistance, aesthetic appeal, and ability to maintain color over time, anodized aluminum sheets find extensive use in architecture, automotive, and electronics industries.