Customized 1.2-7.0mm patterned aluminum sheet for anti-skid use in automobiles/ships 5052 5083 3003

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Anti-skid patterned aluminum sheet is a product with concave and convex patterns on the surface of the aluminum sheet, which has anti-skid function. Our company produces anti-skid aluminum sheets. Common patterned aluminum sheets in the market include five-rib, three-rib, one-rib, diamond-patterned anti-skid aluminum sheets, which are suitable for anti-skid use in various vehicles, containers, stairs, ship deck anti-skid equipment and other buildings.

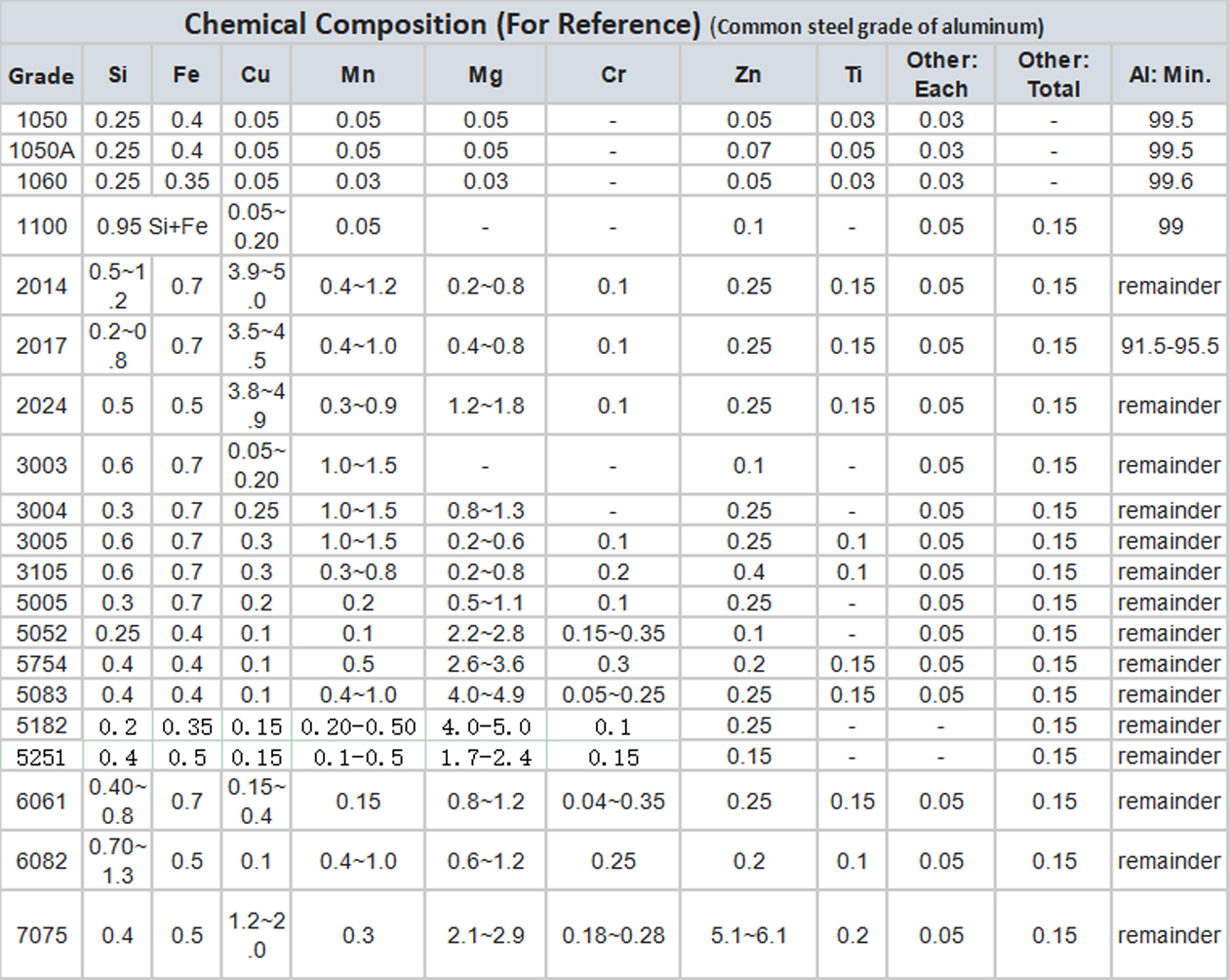

The main products of patterned aluminum sheets are 1xxx series, 3xxx series, 5xxx series, and 6xxx series aluminum alloy sheets. The product surface is clean, shiny, without burrs, black wire, etc. The product models are complete and can be customized according to customer needs and exported overseas.

Specifications of anti-slip patterned aluminum sheets:

| Alloy | 5000 series: 5052 5754 5083 5086 6000 series: 6061 6063 6082 3000 series: 3003 3004 3005 3105 1000 series: 1050 1060 1100 |

| Temper | O H12/H22 H14/H24, H16, H18, H114 H194, T6 T4, etc. |

| Thickness | 0.7-10.0mm |

| Width | 20-2100mm |

| Length | 1000mm, 2000mm, 2440mm, 3000mm, 3048mm, 6000mm, or as required |

| Embossed pattern | small 5bar, large 5bar, 3bar, 2bar, 1bar, diamond, propeller, pointer, etc. |

| Advantages | 1. Accurate size, good anti-slip effect, wide range of applications 2. Strong plasticity, easy to form, excellent processing performance. 3. Embossed aluminum sheet can form a dense and solid oxide film on the aluminum surface to prevent the intrusion of oxygen, so it has good corrosion resistance. 4. Good elongation and tensile strength, can fully meet normal processing requirements (stamping, stretching), high formability. 5. The surface quality of the patterned sheet is good, without oil spots, waves, scratches, roller marks, neat cutting edges, and no burrs. |

| Application | Floors of aircraft, light rail, and vehicles; decks, stairs, ladders, racks, temporary scaffolding, platforms, cantilever beams, elevators, etc. of ships. |

| Samples | Free samples |

| MOQ | 1 tons |

Advantages of anti-slip patterned aluminum sheet:

1. Excellent anti-slip performance, widely used

2. High hardness surface, strong wear resistance, long service life

3. Corrosion resistance

4. Lightweight, easy to install

5. Beautiful appearance

- Q: This question asks for signs or methods to identify if a building is utilizing aluminum sheets in its construction or design.

- <p>To determine if a building is using aluminum sheets, look for the following signs: 1) Shiny, metallic appearance, which is characteristic of aluminum. 2) Lightweight construction, as aluminum is less dense than many other metals. 3) Resistance to corrosion and weathering, a common feature of aluminum. 4) Use in areas prone to water or moisture, as aluminum is water-resistant. 5) Check for the manufacturer's specifications or building materials list. If possible, consult with the building's architect or engineer for confirmation.</p>

- Q: Can aluminum sheets be used for bus bodies?

- Indeed, bus bodies can be constructed using aluminum sheets. Aluminum, renowned for its lightweight and durable qualities, is frequently utilized in the fabrication of bus bodies. Its exceptional strength-to-weight ratio renders it an optimal selection for bus manufacturers, as it enhances fuel efficiency and expands payload capacity. Moreover, aluminum exhibits remarkable resistance to corrosion, a valuable attribute for vehicles perpetually confronted with diverse weather conditions. Additionally, aluminum can be effortlessly shaped and fabricated, enabling the production of intricate forms and designs. Consequently, aluminum sheets are widely favored for bus bodies owing to their robustness, lightness, resistance to corrosion, and adaptability.

- Q: Are aluminum sheets fire-resistant?

- Aluminum sheets are not inherently fire-resistant, but they do have properties that make them more fire-resistant compared to other materials. Aluminum has a high melting point of 1220°F (660°C), which means it will not ignite or burn easily under normal conditions. Additionally, aluminum has a low ignition temperature and does not release flammable gases when heated. When exposed to fire, aluminum sheets form a protective oxide layer that acts as a barrier, preventing further combustion and slowing down the spread of flames. This oxide layer also helps to insulate the aluminum from the heat, reducing the risk of structural failure. However, it is important to note that while aluminum sheets have better fire resistance than materials like wood or plastic, they can still be damaged or deformed by intense heat. Therefore, it is crucial to consider other fire safety measures, such as using fire-resistant coatings or implementing fire suppression systems, in order to ensure maximum protection against fire hazards.

- Q: Do 101 aluminum sheets have any specific anti-corrosion properties?

- Indeed, specific anti-corrosion properties are possessed by 101 aluminum sheets. When exposed to oxygen, aluminum naturally forms a protective oxide layer on its surface, which acts as a barrier against corrosion. This oxide layer, also referred to as aluminum oxide, exhibits a high resistance to both rust and corrosion. Moreover, the corrosion resistance of 101 aluminum sheets is further enhanced by the addition of small amounts of iron and silicon to the alloy. These sheets are frequently utilized in applications where corrosion resistance is of utmost importance, such as in marine environments, chemical processing plants, and outdoor structures. Nevertheless, it is crucial to acknowledge that although aluminum is highly resistant to corrosion, it can still be susceptible to certain types of corrosion under specific conditions, such as pitting corrosion in chloride-rich environments. Therefore, proper care and maintenance should still be practiced to ensure the durability and effectiveness of 101 aluminum sheets in preventing corrosion.

- Q: What is the composition of 101 aluminum sheets?

- The composition of 101 aluminum sheets typically consists of 99.5% pure aluminum with trace amounts of other elements such as iron and silicon.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of high-rise buildings?

- <p>Yes, aluminum sheets can be used for exterior walls in high-rise buildings. They are lightweight, durable, and resistant to corrosion, making them suitable for such applications. Aluminum sheets can also be coated or anodized to provide additional protection and aesthetic appeal. They are often used in combination with other materials or as a cladding system to enhance the building's appearance and energy efficiency.</p>

- Q: Bauxite ore contains aluminum oxide, which is decomposed using electricity to produce aluminum metal and oxygen. What mass of aluminum metal can be produced from 125 g of aluminum oxide?I'm really confused and I need help. Thanks.

- Safely Permanently Remove Moles, Warts and Skin Blemishes

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly or sustainable buildings?

- <p>Yes, aluminum sheets can be used for green building projects. They are lightweight, strong, and durable, which reduces the amount of material needed and the energy consumed in transportation. Aluminum is also 100% recyclable, meaning it can be repurposed without losing quality, reducing waste and the need for new raw materials. Additionally, aluminum has a high reflectivity, which can help in reducing heat absorption and thus lowering cooling costs in buildings. These properties make aluminum a sustainable choice for green building initiatives.</p>

- Q: So I got this stainless steel ring but I took it to this place and apparently its not stainless it's aliminum bc of how light it is but it's really hard so how could it be aluminum?

- Aluminum is a quite soft metal, but so is gold. It is true that aluminum is light in weight but magnesium is even lighter and is common enough that a ring could be made of it. Metals can be made harder by adding small amounts of other metals or even by the way it is heat treated. .

- Q: iron-based alloys over aluminum in structural members of bridges and buildings?

- Because it's lighter with about the same strength as iron alloys

Send your message to us

Customized 1.2-7.0mm patterned aluminum sheet for anti-skid use in automobiles/ships 5052 5083 3003

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords