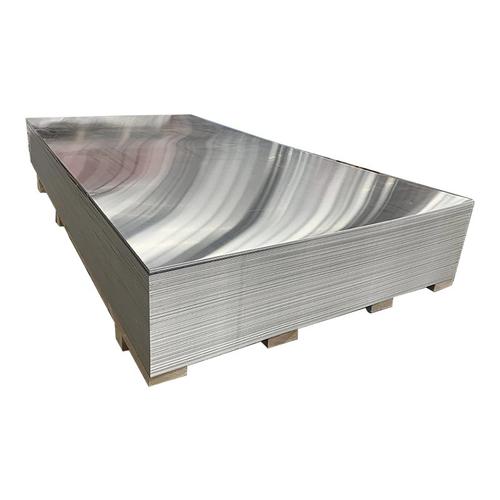

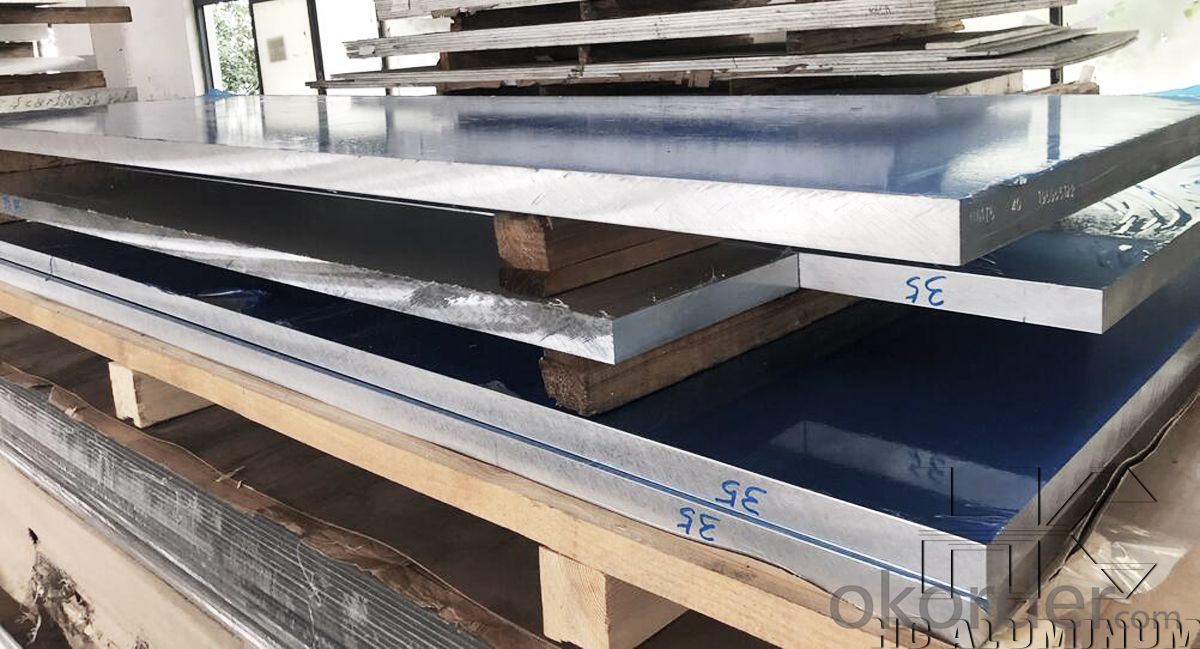

High quality 5083/5754/5052/5182/aluminum sheet for car wheels/doors/hoods

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Automotive aluminum sheets refer to aluminum alloy sheets used in automobile manufacturing. Aluminum is widely used in modern automobile manufacturing due to its lightweight, high strength, corrosion resistance and other advantages. Automotive aluminum sheets usually use 1xxx, 3xxx, 5xxx and 6xxx alloys, such as: 1060, 1100, 3003, 3105, 5052, 5083, 5182, 5454, 6061, 6063, 6005 and other aluminum alloys.

Aluminum sheet for automobile specifications:

Aluminium Alloy | Thickness(mm) | Width(mm) | Temper |

A1050,A1060,A1070,A1100 | 0.2-8.0 | 20-2650 | O,H12,H14,H16,H18,H22,H24,H26 |

A3003,A3004,A3105 | 0.2-8.0 | 20-2650 | O,H12,H14,H16,H18,H22,H24,H26 |

A5052,A5005,A5083,A5754 | 0.2-8.0 | 20-2650 | O,H12,H14,H34,H32,H36,H111,H112 |

A6061,A6082,A6063 | 0.2-8.0 | 20-2650 | T4,T6,T651 |

Material process | CC AND DC | ||

Customerize size | Size can be produced as per clients requirement | ||

Surface | Mill finish ,Color coated(PVDF& PE),Stucco Embossed ,Bright Polish,Anodizing Mirror,Brush,Perforated,Tread plate ,Corrugated etc | ||

Quality Standard | ASTM B209,EN573-1,etc | ||

MOQ per size | 1 ton and sample is available | ||

Payment Terms | TT,L/C, wire transfer, Western Union, etc. | ||

Delivery time | 25-35 working days after payment | ||

Material Quality | Tension levelled ,flat ,Free of defects like oil stain,Roll Marks,Waves,Dents scratches etc ,A+++ quality, production process passed sgs and bv inspection | ||

Application | Construction ,Building,Decoration ,Curtain Wall, Roofing, Mould, Lighting, curtain wall, Construction ,Building,Decoration ,Curtain Wall, Roofing, Mould, Lighting, curtain wall, ship building,Aircraft,Oil Tank ,Truck Body etc | ||

Packing | Standard export worthy wooden pallets and standard packing is about 2 tons/pallet Pallet weight also can be as per client's | ||

Chemical composition

Performance advantages of automotive aluminum sheets:

1. Lightweight: The density of aluminum is low, which helps reduce the weight of the car, improve fuel efficiency, and reduce carbon dioxide emissions.

2. High strength: Alloyed aluminum sheets have excellent strength and deformation resistance to meet the durability requirements of automobile structural parts.

3. Corrosion resistance: Aluminum alloy has better corrosion resistance than steel in humid and salt spray environments, and is suitable for exterior and chassis components.

4. Formability: Aluminum alloy has good ductility, making it easy to manufacture complex body shapes through a variety of processes to meet design requirements.

5. Recyclability: Aluminum is highly recyclable. The recycling process consumes low energy, reduces resource consumption, and improves sustainability.

6. Shock absorption and noise resistance: Aluminum alloy has better shock absorption performance than steel, which helps improve riding comfort.

7. Heat dissipation performance: Aluminum has good thermal conductivity and is suitable for components with high heat dissipation requirements.

8. Appearance and handling: The surface of the aluminum sheet is easy to handle, which improves the appearance and durability and meets the requirements of appearance and wear resistance.

The main applications of aluminum sheets in automobiles include:

1. Body outer panels: Aluminum alloy body panels are lighter, which helps reduce the weight of the car, improve fuel efficiency and reduce emissions, and also has good corrosion resistance.

2. Doors and hood: Aluminum alloy materials help reduce the weight of these parts while maintaining high strength and safety.

3. Chassis and structural parts: Aluminum alloy materials are often used in automobile chassis and other load-bearing parts to reduce vehicle weight and improve vehicle controllability.

4. Wheel hub and suspension system: The application of aluminum alloy in these components can effectively reduce the unsprung mass and improve the vehicle's handling performance and comfort.

FAQ:

Q1: How can I get your quotation?

A1: Please mention the alloy and condition, application, thickness, tensile strength, elongation, etc. and we will quote as soon as possible.

Q2: How about the delivery time?

A2: It usually takes about 7-35 days according to different order requirements.

Q3: Can we visit your factory?

A3: Of course, we sincerely welcome you to visit us at any time!

Q4: What is your product range?

A4: Our company's products include 1-8 series of aluminum foil, aluminum coils, aluminum sheets, aluminum discs, aluminum pattern sheets, etc.

Q5: What is the packaging?

A5: Our products are packed in wooden boxes for sea transportation

Q6: How about the delivery time?

A6: It usually takes about 7-35 days according to different order requirements.

Q7: What is the minimum order quantity?

A7: The minimum order quantity is 2 tons to 5 tons.

- Q: Are the aluminum sheets suitable for manufacturing automotive parts?

- Automotive parts can be effectively manufactured using aluminum sheets. This material, known for its lightweight and durability, provides several advantages in automotive applications. With a high strength-to-weight ratio, it is ideal for producing parts that require strength without burdening the vehicle with excessive weight. Aluminum sheets find widespread use in the production of automotive body panels, including hoods, doors, and fenders. Their malleability facilitates easy shaping and forming, enabling manufacturers to create intricate designs and complex details. Moreover, aluminum exhibits excellent corrosion resistance, ensuring longevity and reduced maintenance for the automotive parts made from it. In addition, aluminum's exceptional thermal conductivity makes it a suitable choice for components that necessitate heat dissipation, such as radiators and heat exchangers. Its ability to conduct electricity also renders it valuable in the manufacturing of electrical components for vehicles. Overall, the utilization of aluminum sheets in automotive manufacturing offers numerous benefits. Their lightweight nature enhances fuel efficiency, while their strength and durability guarantee the structural integrity of the vehicle. Furthermore, aluminum's corrosion resistance and thermal conductivity make it a reliable option for a variety of automotive parts.

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Aluminum is a versatile material that can be easily manipulated into different shapes and forms, making it ideal for various architectural applications. It is commonly used for exterior cladding, roofing, window frames, and facades, providing a sleek and modern aesthetic to buildings. Aluminum sheets can also be used for decorative purposes, such as wall panels, art installations, signage, and furniture. The lightweight and durable nature of aluminum make it a popular choice for architects and designers looking to create visually appealing and functional structures. Additionally, aluminum is resistant to corrosion, making it suitable for both indoor and outdoor applications.

- Q: I need to install hand rails around a hot tub and wonder if aluminum would work well.

- Aluminum is not a good choice, even if it's anodized, painted, or powder coated. Pool water is corrosive mostly due to the chloride from chlorination. Steel is slightly less prone to corrosion. Plastic or fiberglass is the best choice.

- Q: What is the weight of an aluminum sheet?

- The weight of an aluminum sheet can vary depending on its dimensions and thickness. Aluminum is a lightweight material, so sheets made from it generally have a relatively low weight compared to other metals. To determine the weight of an aluminum sheet, you would need to know the length, width, and thickness of the sheet. By multiplying the dimensions and the density of aluminum (2.7 g/cm³ or 0.0975 lb/in³), you can calculate the approximate weight of the sheet.

- Q: I constructed a small hho generator for experimental purposes. I needed to add a cooling condenser to the unit because of a overheating problem. I was using a old heater core from a vehicle, soldered some joints to make some connections. the solution seemed to have eaten the solder I used, which was normal lead free solder used in water pipes. I was going to invest into a trans cooler core which is made of aluminum, but I need to know if the solution will eat up the aluminum. I also thought about using a condenser core from a broken window a/c, which is made of copper tubing. any advise would be very help full

- Aluminum, yes; copper, no. Aluminum is attacked by both acids and bases (it is what is called amphoteric); copper is attacked by neither -- although nitric acid will attack copper by oxidizing it. Solder joints may be attacked by acid, but may be more or less immune to attack by strong bases, depending on what is in the solder.

- Q: Are the aluminum sheets suitable for manufacturing marine propellers?

- Yes, aluminum sheets are suitable for manufacturing marine propellers. Aluminum is a lightweight and corrosion-resistant material, making it ideal for use in marine environments where propellers are constantly exposed to water and harsh conditions. Aluminum propellers offer several advantages including high strength-to-weight ratio, improved fuel efficiency, and reduced maintenance costs. Additionally, aluminum is a cost-effective option compared to other materials such as stainless steel or bronze. Therefore, aluminum sheets are a suitable choice for manufacturing marine propellers.

- Q: Are aluminum sheets suitable for electronics applications?

- Yes, aluminum sheets are suitable for electronics applications. Aluminum is lightweight, highly conductive, and has good thermal properties, making it an ideal material for various electronic components such as heat sinks, enclosures, and printed circuit boards. Additionally, aluminum is corrosion-resistant and cost-effective, making it a popular choice in the electronics industry.

- Q: What is aluminum sheet material L2?

- L2 is the name of the brand of aluminium plate in our country, which is the 1060 brand now!L1 is 1070L2 is 1060L3 is 1050L4 is 1030L5-1 is 1100And LF-21, or 3003, LF-1, or 3004! Wait

- Q: Are aluminum sheets suitable for storage tanks?

- Depending on the specific requirements and purpose of the tank, aluminum sheets can be a suitable option for storage tanks. Aluminum is known for being lightweight and resistant to corrosion, making it an excellent material choice for a range of storage applications. It provides structural integrity and durability, allowing it to withstand challenging environments and weather conditions. Moreover, aluminum has a high strength-to-weight ratio, enabling it to support heavy loads while still being relatively light. Nevertheless, it is crucial to consider the tank's contents and seek advice from experts to ensure that aluminum is the appropriate material for the specific storage needs.

- Q: What are the different types of alloys used in aluminum sheet?

- There are several different types of alloys used in aluminum sheet. Some of the most commonly used alloys include: 1. 3003 alloy: This alloy is known for its excellent resistance to corrosion and is often used in applications where exposure to moisture is a concern. It is also easy to form and weld, making it a popular choice for various structural components. 2. 5052 alloy: This alloy is highly corrosion-resistant and has good formability. It is often used in marine and automotive applications, as well as in architectural elements. 3. 6061 alloy: This alloy offers excellent strength and is commonly used in applications that require high structural integrity. It is often used in aerospace and marine industries, as well as in the construction of heavy-duty machinery. 4. 7075 alloy: This alloy is known for its high strength-to-weight ratio and is often used in aerospace and defense applications. It is also used in the manufacturing of bicycle frames, rock climbing equipment, and other high-performance applications. 5. 2024 alloy: This alloy is known for its high strength and excellent fatigue resistance. It is often used in aerospace applications, as well as in the production of structural components and fasteners. These are just a few examples of the many different types of alloys used in aluminum sheet. Each alloy has its own unique properties and advantages, making it suitable for specific applications and industries.

Send your message to us

High quality 5083/5754/5052/5182/aluminum sheet for car wheels/doors/hoods

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords