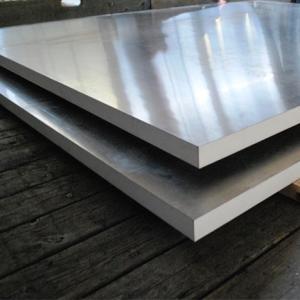

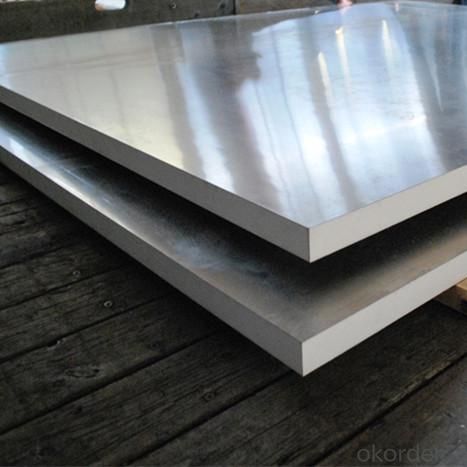

Thin Sheets of Aluminum 5052 - Thickness 0.1mm to 500mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Aluminum Plates 5052

Alloy Number | AA1050 , AA1060 ,AA1070 ,AA1100 etc. |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Plates 5052

Aluminum Plates is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

CNBM produces aluminum plates which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

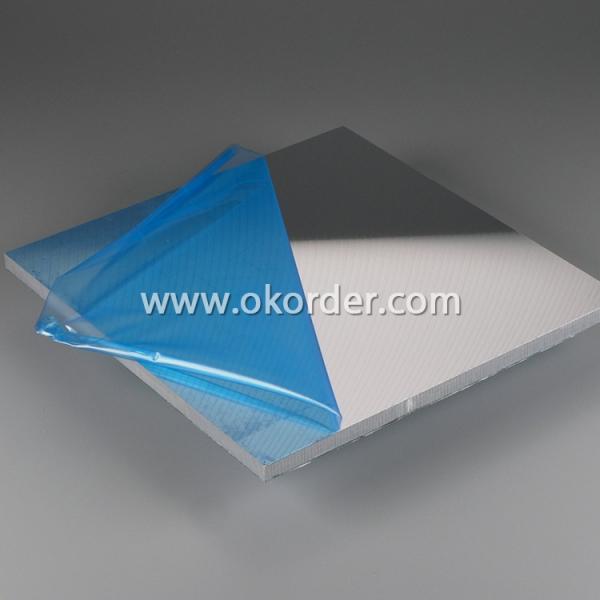

3 Packaging & Delivery of Aluminum Plates 5052

Packaging:Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment:the goods will be delivered in 40 days after getting the buyer's payment.

4 Production Flow of Aluminum Plates 5052

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

5052-H32 Aluminum Plate - (ASTM B209, QQ-A-250/8) Superior corrosion resistance, good weldability, with excellent formability, makes 5052 Aluminum Plate a common choice for chemical, marine or saltwater applications. 5052 Aluminum Plate applications include: tanks, drums, marine hardware, boat hulls, etc.

Non-magnetic, Brinell = 60, Tensile = 33,000, Yield = 28,000 (+/-)

- Q: How does the surface finish affect the optical properties of aluminum sheet?

- The optical properties of aluminum sheet are significantly influenced by its surface finish. Optimal light reflection and minimal scattering are achieved with a smooth surface finish, leading to heightened reflectivity. Consequently, this amplifies the brightness and reflectiveness of the aluminum sheet. Conversely, a rough or textured surface finish on aluminum sheet provokes light scattering in various directions, thereby diminishing reflectivity. Consequently, this yields a lackluster and less reflective appearance. Furthermore, the surface finish has an impact on the visual aspect of any coatings or films applied to the aluminum sheet. A smooth surface finish promotes superior adhesion and uniformity of coatings, thus augmenting their optical properties. To conclude, the optical properties of aluminum sheet are improved with a smooth surface finish, as it enhances reflectivity and diminishes scattering, ultimately resulting in a more vibrant and reflective appearance.

- Q: What are the standard sizes of aluminum sheets?

- Aluminum sheet sizes can differ based on the manufacturer and specific needs. Nevertheless, there are several standard sizes commonly found for aluminum sheets. These include 4 feet by 8 feet (1.2 meters by 2.4 meters), 4 feet by 10 feet (1.2 meters by 3 meters), and 5 feet by 10 feet (1.5 meters by 3 meters). These sizes are widely utilized across various industries and are easily accessible in the market. Furthermore, specialized aluminum sheet suppliers can provide custom sizes tailored to meet specific project requirements.

- Q: Can the aluminum sheets be used for manufacturing furniture?

- Yes, aluminum sheets can be used for manufacturing furniture. Aluminum is a lightweight and durable material that can be easily shaped and formed into various furniture designs. It is also corrosion-resistant, making it suitable for both indoor and outdoor furniture applications.

- Q: This question asks for a comparison between aluminum sheets and other roofing materials, highlighting their differences.

- <p>Aluminum sheets differ from other roofing materials such as asphalt shingles, clay tiles, and metal roofs in several ways. They are lightweight, durable, and resistant to corrosion, making them ideal for coastal areas. Aluminum sheets offer a sleek, modern aesthetic and can be easily recycled, contributing to their environmental friendliness. Unlike asphalt shingles, which have a shorter lifespan, aluminum sheets are long-lasting and can withstand extreme weather conditions. They also don't require the same level of maintenance as clay tiles, which can crack over time. While metal roofs can be similar to aluminum in terms of durability, aluminum sheets are typically more cost-effective and offer a wider range of colors and finishes.</p>

- Q: This question asks for methods to determine the reliability of a supplier for aluminum sheets.

- <p>To determine if your supplier is reliable for supplying aluminum sheets, consider the following: Check their track record and customer reviews for consistency and quality. Assess their industry certifications, such as ISO standards, which indicate commitment to quality management. Evaluate their supply chain transparency and their ability to meet delivery timelines. Look into their financial stability to ensure they can sustain operations. Request samples to test the quality of their aluminum sheets. Finally, communicate openly with them to gauge their responsiveness and professionalism.</p>

- Q: This question asks for a list of adhesive types that are suitable for bonding aluminum sheets. It is important to provide a variety of options to give a comprehensive answer.

- <p>There are several types of adhesives used for bonding aluminum sheets together, including epoxy resins, which offer strong adhesion and resistance to heat and chemicals; polyurethane adhesives, known for their flexibility and durability; acrylic adhesives, which provide good adhesion and are easy to use; cyanoacrylates or 'super glues,' which bond quickly and are great for small, precise applications; and silicone adhesives, which are excellent for high-temperature applications and offer flexibility. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, and resistance to environmental factors.</p>

- Q: How to carry out drawing process in aluminium plate

- Wire drawing aluminum plate is now in the field of production and processing, or in the accessories of electronic products have a very good application, in order to wire drawing aluminum, drawing the process is still very important. How to make the drawing more uniform and beautiful, here is a look at ways and methods to help you successfully complete the production.In the process of drawing, it is necessary to make use of sand paper to do silk scraping treatment.

- Q: Could ring-pull can be transformed as aluminum sheet?

- Yes

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed. Roll forming is a process in which a continuous strip of metal, in this case, aluminum, is fed through a series of rollers to gradually shape it into a desired profile or shape. Aluminum is an ideal material for roll forming due to its malleability and ductility, allowing it to be easily bent, curved, and formed into various shapes. It is commonly used in industries such as construction, automotive, and aerospace for applications that require lightweight yet durable components.

- Q: Are aluminum sheets suitable for heat sinks?

- Yes, aluminum sheets are suitable for heat sinks. Aluminum is a lightweight and highly conductive metal, making it an excellent choice for dissipating heat. It has a high thermal conductivity, which means it can efficiently transfer heat away from the source and spread it across a larger surface area. Additionally, aluminum has good corrosion resistance, which is important for heat sinks that may be exposed to moisture or other environmental factors. The malleability and ease of fabrication of aluminum sheets also make them versatile for creating various heat sink designs to meet specific cooling requirements. Overall, aluminum sheets are widely used in heat sink applications due to their excellent thermal conductivity, lightweight nature, corrosion resistance, and ease of manufacturing.

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2002 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Thin Sheets of Aluminum 5052 - Thickness 0.1mm to 500mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords