5005 Aluminum Plate

5005 Aluminum Plate Related Searches

5000 Series Aluminum Plate 5052 Aluminum Plate 5454 Aluminum Plate 5052 0 Aluminum Plate 5 Aluminum Plate 5000 Series Cast Aluminum Plate 5086 Aluminum Plate 0.5 Aluminum Plate 5mm Aluminum Plate Aluminum Plate 5mm T5mm Aluminum Plate Aluminum Fifth Wheel Plate 1/4 5052 Aluminum Plate 5 16 Aluminum Plate Aluminum 5th Wheel Plate 5754 Aluminum Plate 5mm Thick Aluminum Plate Alca 5 Aluminum Plate 1050 Aluminum Plate 5456 Aluminum Plate 5 Bar Aluminum Plate Atp 5 Aluminum Plate 5 8 Aluminum Plate 5083 0 Aluminum Plate 5083 Cast Aluminum Plate 5052 H32 Aluminum Plate 5052-H32 Aluminum Plate 1350 Aluminum Plate 1.5 Aluminum Plate 3004 Aluminum Plate5005 Aluminum Plate Supplier & Manufacturer from China

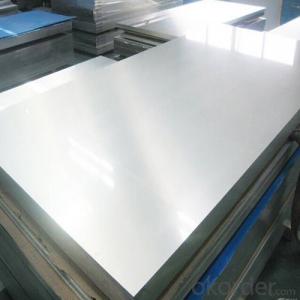

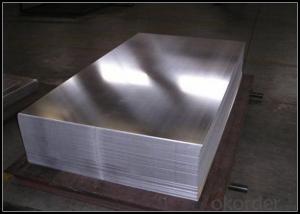

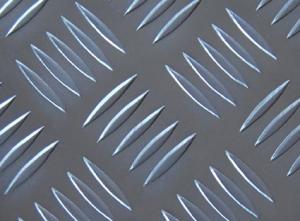

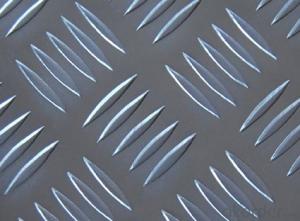

5005 Aluminum Plate is a type of aluminum alloy known for its excellent corrosion resistance, formability, and weldability. It is widely used in various industries, including automotive, aerospace, and construction, due to its lightweight and durable properties. This alloy is particularly suitable for applications where resistance to corrosion is crucial, such as in marine environments or chemical processing plants. Okorder.com is a leading wholesale supplier of 5005 Aluminum Plate, offering a vast inventory to cater to the diverse needs of customers across different sectors. With their extensive range of products, Okorder.com ensures that clients can find the precise specifications and quantities they require for their projects.Hot Products