0.24mm 1050 Aluminum Flat Sheets and Plates

- Loading Port:

- Shanghai

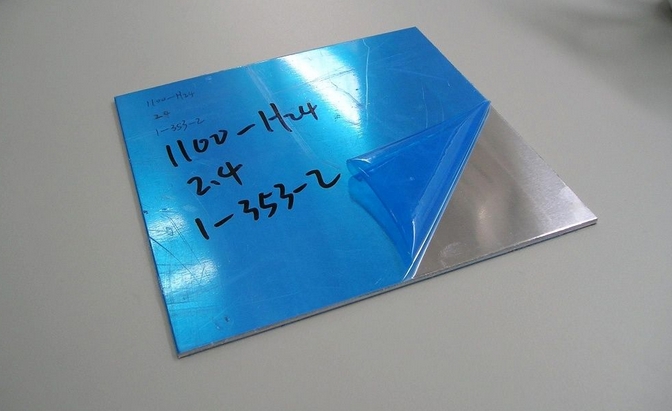

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

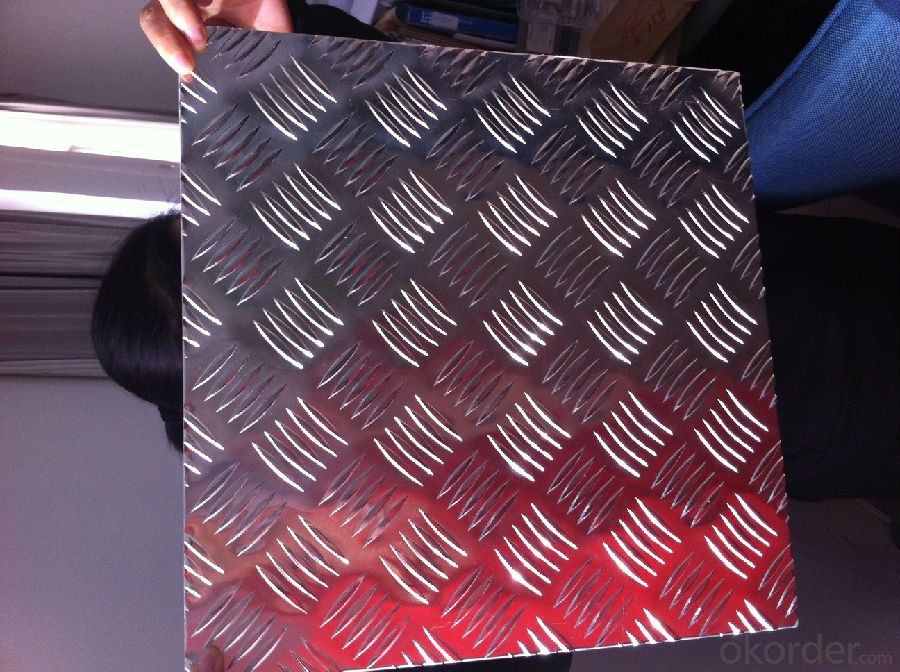

aluminum sheet, cold rolled, hot rolled, alumium coil, aluminum checkered sheet, aluminum mirror finish sheet are all our standard productions, etc.

which are widely used in the field of construction and decoration field, etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the length range:

---It is from 2000mm to 6000mm, etc.

what is your MOQ noramlly?

---normally it is around 5 tons/each size.

how many tons did you export in each year?

---normally it is around 8000 tons totally.

which countries did you export before?

----normlaly is is all over the world, etc.

- Q: Are aluminum sheets suitable for wastewater treatment applications?

- Yes, aluminum sheets are suitable for wastewater treatment applications. Aluminum is highly resistant to corrosion and can withstand harsh chemicals commonly found in wastewater. Additionally, aluminum sheets can be easily formed into various shapes and sizes, making them suitable for use in tanks, pipes, and other wastewater treatment equipment.

- Q: How do aluminum plates paint?

- Pretreatment is usually required. Acid and alkali cleaning can be done either by oil or by xylene,The paintings do not know, but most of them are painted or printed on the aluminum plate, usually by heat transfer, silk screen, or decorative board, which is sprayed directly and then painted.

- Q: Can 101 aluminum sheets be anodized for medical equipment applications?

- Yes, 101 aluminum sheets can be anodized for medical equipment applications. Anodizing is a process that enhances the corrosion resistance and durability of aluminum, making it suitable for various industries, including medical equipment.

- Q: What are the weight considerations when using aluminum sheets?

- Weight considerations play a significant role in various applications and industries when utilizing aluminum sheets. Aluminum's lightweight nature makes it a preferred choice in scenarios where weight reduction is essential. Here are some key factors to consider regarding weight when using aluminum sheets: 1. Structural Weight Reduction: Industries such as aerospace, automotive, and construction commonly use aluminum sheets to reduce the overall weight of structures. Aluminum's lightweight nature allows for improved fuel efficiency in vehicles, increased payload capacity, and lower transportation costs for construction materials. 2. Design Flexibility: Aluminum sheets offer greater design flexibility compared to heavier materials due to their low density. This weight advantage enables engineers and designers to create intricate shapes and structures without compromising on strength and durability. 3. Handling and Installation: The lightweight nature of aluminum sheets simplifies handling and installation processes. It requires fewer manpower and equipment, reducing labor costs and increasing productivity. Additionally, aluminum's low weight makes it easier to transport and maneuver during assembly or installation. 4. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion. This eliminates the need for additional coatings or treatments, reducing weight and maintenance requirements. 5. Energy Efficiency: Using aluminum sheets can help reduce energy consumption in various applications. For instance, lightweight aluminum roofing in the construction industry can improve the energy efficiency of buildings by reducing the load on heating and cooling systems. 6. Transport and Shipping: Aluminum's lightweight property significantly impacts transportation and shipping costs. The reduced weight of aluminum sheets allows for larger quantities to be transported in a single shipment, thereby reducing fuel consumption and emissions. 7. Electrical Applications: Aluminum is an excellent conductor of electricity. Its lightweight nature makes it an ideal choice for electrical wiring, conductors, and other electrical components, reducing the overall weight of electrical systems. It is important to note that while weight reduction is advantageous in many applications, the specific requirements and constraints of each project should be considered. Proper engineering analysis and consultation are crucial to ensure that the selected aluminum sheet meets the desired weight considerations while maintaining structural integrity and performance.

- Q: An aluminum clock pendulum having a period of 1.00 s keeps perfect time at 20 degrees celcius. (A) When placed in a room at a temperature of -5.0 Celcius, will it gain or lose time? (B)How much time will it gain or lose every hour.

- this concerns change in length of aluminum due to fall in temp T(20 C) = 2pi√(L20/g = 1 sec L20 = g/4pi^2 ----------- (1) T(-5 C) = 2pi√(L5/g L5 = T(5)^2*g /4pi^2 ----------- (2) coefficient of linear expansion of aluminum = alpha alpha = delta L/L* delta T 23*10^-6 = (L5 - L20) /L20*(- 5 - 20) (L5 - L20) /L20 = - 25*23*10^-6 L5/L20 = 1 - 25*23*10^-6 = 0.999425 --- (3) L5 decrease in length T(5) will reduce (2) / (1) L5/L20 = [T(5)^2*g /4pi^2] * [4pi^2/g] = 0.999425 [T(5)^2] = 0.999425 T(5) = 0.9997 sec this is period when in (-5 C) room a) pendulum gains time in cold room word gains is used because it takes less in 1 oscillation. b) it gains time = 1 - 0.9997 = 0.0003 sec in 1 sec gain in every hour = 0.0003*3600 = 1.08 sec

- Q: Are aluminum sheets suitable for electrical transformers?

- Indeed, electrical transformers can certainly make use of aluminum sheets. Aluminum, being a highly conductive material, presents numerous benefits when employed in transformers. Primarily, its electrical resistance is lower in comparison to other materials such as copper, enabling efficient transmission of electrical energy. Consequently, this leads to reduced energy losses and enhanced overall performance. Furthermore, aluminum possesses the advantage of being lightweight, rendering it easier to handle and install. Moreover, it is also more economical than copper, thus making it the preferred option for extensive transformer applications. All in all, aluminum sheets offer a dependable and effective resolution for electrical transformers.

- Q: Is aluminium plate the same as aluminium alloy?

- Oh, No. aluminum contains only aluminum, and there are some other metals besides aluminium.

- Q: Are 101 aluminum sheets suitable for agricultural machinery?

- Yes, 101 aluminum sheets are suitable for agricultural machinery.

- Q: There are about 200 holes on the aluminum plate to be machined. There are 100 M12 thread holes, and the rest are 15MM through holes. The tolerance is +0.02. Seeking detailed processing technology, is the first hole or first processing plane, how to control the amount of deformation of the plate, if the milling process can not guarantee flatness, on the grinder, then the 2 surfaces to stay 2MM margin? Are there any 15MM through holes that can be used to maintain tolerances, or do they need to be boring?. Great God advice, the best detail. Aluminum so much done before, no experience, if it does it scrapped.

- Such a large plate flatness 0.1 you don't need it, basically do not, we used 1000*700 processing board, directly buy imported aluminum plate, ensure the factory within 0.05, leveling back after processing to find professional leveling company OK, I was also called grinding waste, the deformation of grinding plate will be great, so there is no need to consider

- Q: What are the different manufacturing methods for aluminum sheets?

- There are several different manufacturing methods for aluminum sheets, each with its own unique characteristics and applications. 1. Rolling: The most common method of manufacturing aluminum sheets is through rolling. In this process, large slabs of aluminum are passed through a series of rollers, which reduce the thickness of the slab and increase its length. This method can produce sheets with consistent thickness and excellent surface finish. 2. Extrusion: Extrusion is another method used to manufacture aluminum sheets. In this process, a heated billet of aluminum is forced through a die, resulting in a continuous length of sheet. Extrusion allows for complex shapes and profiles to be created, making it suitable for applications such as building construction and automotive components. 3. Casting: Casting involves pouring molten aluminum into a mold and allowing it to cool and solidify into a sheet shape. This method is often used for producing thicker sheets or sheets with specific alloy compositions. Casting can offer unique properties and is commonly used in industries such as aerospace and defense. 4. Cladding: Cladding is a process where a thin layer of aluminum is bonded to another material, such as steel or composite materials. This method combines the desirable properties of aluminum, such as corrosion resistance and lightweight, with the strength and durability of the base material. Clad aluminum sheets are commonly used in construction, transportation, and electrical industries. 5. Powder metallurgy: Powder metallurgy involves the formation of aluminum sheets from powdered aluminum particles. The powder is compacted into a desired shape and then sintered at high temperatures to fuse the particles together. This method is used for producing complex shapes and can provide improved mechanical properties. Each manufacturing method for aluminum sheets has its own advantages and disadvantages, depending on the desired properties, application, and cost considerations. Therefore, it is important to carefully select the most appropriate method based on the specific requirements of the project.

Send your message to us

0.24mm 1050 Aluminum Flat Sheets and Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords