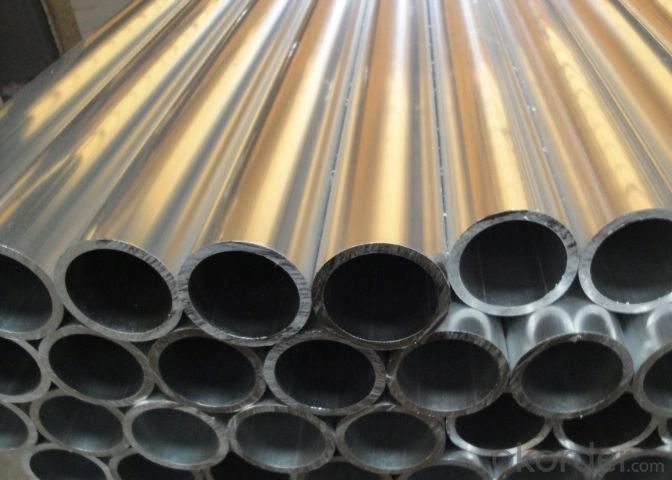

Aluminum Pipes 3005

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Pipe 3005:

1.Specifications of aluminium pipe 3005

1)Alloy:3005;

2)Wall thickness : 0.4mm-80mm ;

3)Outer diameter : 10-900mm ;

4)Length : 6m-9m.

2.Application of aluminium pipe 3005:

aluminum window, door, curtain wall, hand railing, normal aluminum profile, decorative and industrial aluminum profile

3.Features of aluminium pipe 3005:

High weather resistance anti scratch anticorrosion and good weather resistance subtle edges and elegant appearance and easy processing and installation high brightness and hardness.

4.Packaging of aluminium pipe 3005:

protection foam heat contracted plastic film,Wooden packing , Metal pallet

- Q: Do you use seamless pipes or aluminium tubes for cold storage?

- First of all, I would like to emphasize that it is not aluminum tube, that is aluminum alloy. 1, the heat transfer performance is not the same. The heat transfer performance of aluminum is better, easy to make the cold air sinking 2, low temperature performance, Aluminum Alloy can reach close to minus 300 DEG C3, then cold storage, use Aluminum Alloy tube instead of air cooler, more power, so the 4 Aluminum Alloy tube light, convenient installation, the investment of 5 Aluminum Alloy, at the same the volume, to 6, lower than the Aluminum Alloy seamless steel tube good environmental performance, will not rust, does not affect the cold in packaged goods. These are the basic items, there are other, that is, the use of the problem, you can consult the tube you want to buy the business, they will tell you about some aspects of the use of matters.

- Q: What are the different pressure testing standards for aluminum pipes?

- There are several pressure testing standards for aluminum pipes, including ASTM B210, ASTM B241, and ASME B31.3. These standards outline specific requirements and procedures for conducting pressure tests to ensure the integrity and safety of aluminum pipes under various operating conditions.

- Q: The length of the aluminum tube is about 180mm, the diameter is 19mm, and the wall thickness is about 1mm. It should be bent into the radian of R300. No deformation

- The mandrel with a diameter smaller than the inner diameter of the aluminum pipe is made into two sections, and the aluminum pipe is inserted from both ends (contact at both ends), and the mandrel can be pulled out when bent into the required radian. A mandrel can be made of material that is softer than aluminum, such as lead.

- Q: What is the extrusion process of aluminium tube?

- Process flow is:Billet heating, hot extrusion, cutting, boring, wagon, wool two heating, extrusion, tension or straightening roller leveler, cutting chuck - intermediate annealing, corrosion, inspection, repair, scraped the cold rolling, annealing, quenching, stretching, heading to the whole diameter, straightening, cutting and finished product sampling artificial aging, annealing, inspection and acceptance, oiling and packing

- Q: Aluminum tube processing process prone to deformation, how to solve?

- Analysis of what is caused by deformation, if it is because the aluminum tube in stress, can be resolved by vibration aging treatment

- Q: What is the chemical composition of aluminum pipes?

- The chemical composition of aluminum pipes is primarily composed of aluminum (Al) as the main element.

- Q: Do aluminum pipes expand or contract with temperature changes?

- With an increase in temperature, aluminum pipes undergo expansion, while they contract when the temperature decreases. This behavior is a result of thermal expansion, which refers to the inclination of materials to alter their dimensions, volume, or shape in response to temperature fluctuations. As aluminum is heated, the atoms in the metal absorb energy and experience greater vibrations, leading to expansion. Conversely, when the temperature drops, the atoms lose energy and vibrate less, causing contraction. It is crucial to take these thermal expansion and contraction phenomena into account during the design and installation of aluminum pipes to guarantee a precise fit and optimal functionality.

- Q: What are the different diameters available for aluminum pipes?

- The different diameters available for aluminum pipes can vary widely, ranging from small sizes like ¼ inch or 6.35mm to larger diameters such as 12 inches or 304.8mm. The specific diameters available will depend on the manufacturer and the intended application of the aluminum pipes.

- Q: Are aluminum pipes suitable for industrial applications?

- Yes, aluminum pipes are suitable for industrial applications. Aluminum pipes offer several advantages that make them an excellent choice for various industrial settings. Firstly, aluminum is lightweight, which makes it easy to handle and transport. This makes installation and maintenance more convenient. Additionally, aluminum pipes have excellent corrosion resistance, making them suitable for applications where exposure to moisture or chemicals is a concern. Furthermore, aluminum pipes have good thermal conductivity, meaning they can efficiently transfer heat, making them suitable for applications that require temperature control. Lastly, aluminum pipes are highly durable and have a long lifespan, reducing the need for frequent replacements. Overall, the unique properties of aluminum pipes make them a reliable and cost-effective option for industrial applications.

- Q: resulting in the pipe can not be used after folding, how to deal with? Fifteen08 years to buy three AUX air-conditioning, moving this year, the pipe was folded, and then installed, AUX said after the sale of the pipe can not be used, to replace all new, because the aluminum pipe can not be welded. We all know that the tube is very expensive, then bought 5 meters or so, I think it will not have to spend money again, I did not expect, because of this reason, even for old pipes, the installation of new tubes, but also spend nearly 1000 yuan. When I bought it, I didn't think they would use the aluminum tube. I thought it was copper. It was entirely cost saving by the factory, which made the consumer pay the bill. I was so angry that I didn't buy anything from AUX any more. Would you like to ask if you have ever touched this situation? What can you do to reuse the old pipes?

- You only have to spend this money, or who help you install.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Pipes 3005

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords