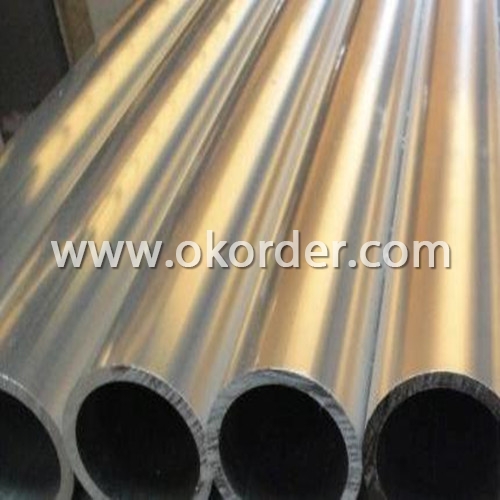

Aluminum Pipes 3xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminum Pipes 3XXX

Alloy Number | AA 3XXX |

Temper | O, F,H112,T4,T5,T6,T3,T8 |

Thickness | 0.5-50mm |

Length | <=13m |

Diameter | Outer: 9-500mm |

Standard | GB/5237.2-2004, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of Aluminum Pipes 3XXX

Aluminum pipes are widely used for building construction, housing decorations, industry & agriculture & architecture usage etc.

3. Packaging & Delivery of Aluminum Pipes 3XXX

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of Aluminum Pipes 3XXX

Casting--extruding--cutting--coating—further processing--packing

- Q: Can aluminum pipes be bent or shaped?

- Yes, aluminum pipes can be bent or shaped. Aluminum is a malleable metal, meaning it can be easily formed into different shapes without breaking. There are various methods available to bend or shape aluminum pipes, such as using a pipe bender, heat bending, or hydraulic press. The specific technique used will depend on the desired shape and the thickness of the aluminum pipe. It is important to note that the bending or shaping process should be done carefully to avoid damaging the pipe or causing any structural weaknesses.

- Q: What is an aluminum pipe?

- An aluminum pipe is a cylindrical hollow tube made primarily from aluminum, a lightweight and corrosion-resistant metal. It is commonly used in various industries and applications due to its advantageous properties. Aluminum pipes are known for their durability, high strength-to-weight ratio, and excellent conductivity. They are often used for plumbing systems, HVAC (heating, ventilation, and air conditioning) systems, irrigation, and transportation of fluids or gases. Additionally, aluminum pipes find extensive use in structural applications, such as scaffolding, handrails, and support structures, where their lightweight nature is beneficial. Overall, aluminum pipes are versatile, reliable, and widely utilized in numerous industries.

- Q: Are aluminum pipes suitable for paper mills?

- Yes, aluminum pipes are suitable for paper mills. Aluminum is highly resistant to corrosion and can withstand the harsh chemicals and high temperatures often found in paper mills. Additionally, aluminum pipes are lightweight, making them easy to install and maintain in the industrial setting of paper mills.

- Q: Can you tell me what kind of pipe bender is used to bend the aluminum tube? It's not easy to wrinkle or break

- It depends on what kind of bent? Is the arc or angle? I feel the problem is not bending, but in bending die, bending tubes can best be used cast iron core Nilun bending die

- Q: Can aluminum pipes be used for hydroponic systems?

- Certainly! Hydroponic systems can indeed utilize aluminum pipes. These pipes possess qualities such as being lightweight, durable, and highly resistant to corrosion, rendering them an excellent option for hydroponic applications. By effortlessly cutting and assembling them, one can construct a personalized hydroponic system tailored to the precise requirements of various plants. Moreover, aluminum pipes exhibit commendable thermal conductivity, promoting efficient heat transfer within the system. Nonetheless, it is imperative to bear in mind that proper coating or lining of the aluminum pipes is crucial to prevent any potential leaching of aluminum into the nutrient solution, as this can prove detrimental to the plants.

- Q: Can aluminum tubes be used instead of compressed air pipes?

- Definitely.In principle, as long as the strength and performance indicators are adequate, then many materials are available, and aluminum is no exception.In fact, there are special tubes for air compression pipes, such as these

- Q: Can aluminum pipes be used for airport terminals?

- Yes, aluminum pipes can be used for airport terminals. Aluminum is a popular material choice for various applications in airport terminals due to its numerous advantages. Firstly, aluminum is lightweight, which makes it easier to handle during construction and installation. This can lead to cost savings and faster project completion times. Additionally, aluminum pipes are corrosion-resistant, which is crucial in environments like airport terminals where exposure to moisture, humidity, and chemicals is common. This resistance to corrosion ensures the longevity and durability of the pipes, reducing maintenance and replacement costs in the long run. Another advantage of using aluminum pipes in airport terminals is their excellent thermal conductivity. Aluminum pipes can efficiently transfer heat, making them suitable for applications such as heating, ventilation, and air conditioning (HVAC) systems. This property can contribute to energy efficiency and cost savings for the terminal's operations. Furthermore, aluminum is a sustainable material as it is easily recyclable. This aligns with the increasing emphasis on environmental responsibility in modern construction practices. By using aluminum pipes, airport terminals can contribute to sustainable building practices and reduce their carbon footprint. In summary, aluminum pipes can be effectively used in airport terminals due to their lightweight nature, corrosion resistance, thermal conductivity, and sustainability. Considering these advantages, it is a suitable material choice for various applications within airport terminal infrastructure.

- Q: Is there any difference between the installation of air conditioning aluminum tube and copper tube?

- When installing the air conditioner, the pipe often needs bending, and the copper tube has no aluminum tube bending resistance, and the refrigerating effect will not be affected. But the disadvantage of the aluminum pipe is that it can not make bell mouth, poor pressure resistance, no oxidation resistance, it is easy to leak point, if there is no wrapped insulation cotton, that is a hidden danger.

- Q: Freezer aluminium tube can be used for several years

- The aluminum pipe is more corrosion resistant than the iron tube, and the iron pipe is not corrosion resistant, so I suggest you choose the aluminum pipe!In fact, the best or copper pipe, but now no manufacturers have produced, mainly or cost!

- Q: What are the different bending techniques for aluminum pipes?

- There are several bending techniques for aluminum pipes, including rotary draw bending, induction bending, and mandrel bending. Rotary draw bending involves using a die and a mandrel to bend the pipe around a bend die. Induction bending uses heat to soften the aluminum pipe before bending it using a bending machine. Mandrel bending utilizes a mandrel inside the pipe to support it during the bending process, preventing it from collapsing or wrinkling.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2004 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Pipes 3xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords