Aluminum Pallet Aluminum Pipes

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Please see more info as belows:

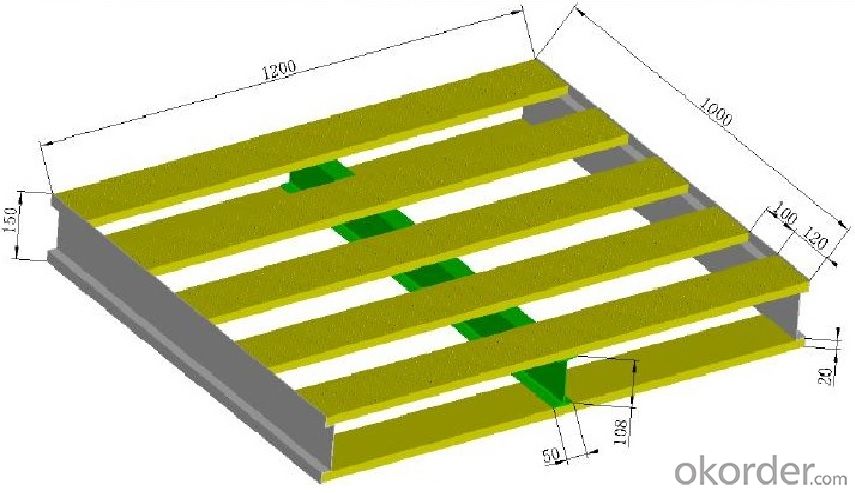

No. | Dimension(mm) | Weight(kg) | Alloy | Dynamic load | Static load | Load mode | Processing type |

1 | 1200×1000×153 | 14.84 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

2 | 1200×1000×150 | 14.38 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

3 | 1200×1000×150 | 21.56 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

4 | 1200×800×150 | 11.90 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

5 | 1200×800×150 | 17.62 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

6 | 1100×1100×150 | 14.39 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

7 | 1100×1100×150 | 20.96 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

8 | 1200×1000×150 | 14.13 | AL6061-T6 | 1.5t | 3t | Single side | Riveting |

9 | 1200×1000×150 | 18.60 | AL6061-T6 | 1.5t | 3t | Double side | Riveting |

- Q: Can aluminum tube and stainless steel pipe be welded directly?

- Can be directly welded, the high quality requirements can be considered by using MG460F welding, flux cored wire, if the demand is not high, you can consider the use of MG400 welding electrode, the cost is relatively low, but can not be repeated for welding, easy to crack.

- Q: Are aluminum pipes affected by exposure to industrial solvents?

- Yes, aluminum pipes can be affected by exposure to industrial solvents. Aluminum is generally resistant to many chemicals, but certain solvents can cause corrosion or deterioration of the metal over time. It is important to select the appropriate type of aluminum alloy and protective coatings to minimize the potential damage caused by exposure to industrial solvents. Regular maintenance and inspections are also crucial to ensure the longevity and performance of aluminum pipes in such environments.

- Q: Can aluminum pipes be used for structural supports in buildings?

- Yes, aluminum pipes can be used for structural supports in buildings. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for structural applications. It has a high strength-to-weight ratio, allowing it to withstand heavy loads while remaining relatively light. Additionally, aluminum pipes can be easily shaped and welded, making them versatile for various structural designs. However, it is important to consider the specific requirements and regulations of each building project before using aluminum pipes as structural supports.

- Q: What is the difference between air conditioning copper tubes and aluminum tubes?

- The copper tube has high heat transfer efficiency, corrosion resistance and good strength, but the price is expensive.The heat transfer efficiency of aluminum pipe is higher, the corrosion resistance is not good, but the price is much cheaper.

- Q: Vanward gas 6B water heater is a copper tube or aluminum tube?

- If genuine, usually copper, and sometimes not necessarily

- Q: My company plans to rust aluminum 15 Phi Phi 8 hit a row of holes, then Phi 8 Phi 15 in aluminum pipe welding, welding oxyacetylene welding using plan copper welding current, using nitrogen or nitrogen and hydrogen in welding. As a result, many welding leaks and air holes were found in aluminum tube welding, and the welding success rate was low. How can I improve it?

- Leakage is a universal phenomenon. For such complex welds, vacuum brazing shall be used. It will cost a lot of money to buy Vacuum ovens. Argon tungsten arc welding.

- Q: Can aluminum pipes be used in HVAC systems?

- Yes, aluminum pipes can be used in HVAC systems. Aluminum is a popular choice for HVAC systems due to its excellent thermal conductivity, corrosion resistance, and lightweight nature. It is commonly used for refrigerant lines, air distribution, and heat transfer applications in HVAC systems.

- Q: Can aluminum pipes be used for geothermal heating systems?

- Yes, aluminum pipes can be used for geothermal heating systems. Aluminum is a durable and corrosion-resistant material that can effectively transport heat in geothermal systems while withstanding the high temperatures and pressures involved.

- Q: Freezer aluminium tube can be used for several years

- Now the refrigerator tube is using aluminum tube or Bondi tube (Bondi tube, that is galvanized steel pipe, in fact, the iron pipe, iron pipe above the paint once lost, it is easy to rust..)

- Q: Can aluminum pipes be threaded?

- Yes, aluminum pipes can be threaded.

Send your message to us

Aluminum Pallet Aluminum Pipes

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords