High Quality Aluminum Plate Alloy 5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Plate Alloy 5052 Description:

Aluminium Plate Alloy 5052 also name Al-Mg alloy. Since there are 3-5% magnesium in this alloy.The main features are low density, high tensile strength, high elongation, good resistance to good performance, good welding performance, good fatigue strength, heat treatment, anodized, can improve the strength of cold processing. In the same area, the weight of Al Mg alloy is lower than that of other series.

2.Main Features of Aluminium Plate Alloy 5052:

PVC Protect Film

Waterproof paper

High Quality

Competitive Price

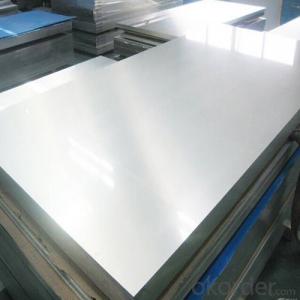

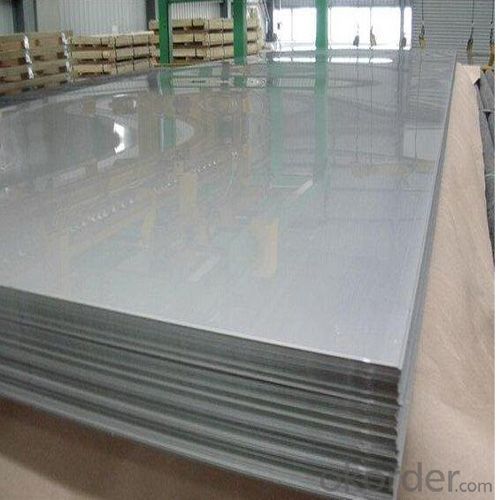

3. Aluminium Plate Alloy 5052 Images:

4. Aluminium Plate Alloy 5052 Specification:

Standard | GB/T3190-2008, GB/T3880-2006, ASTM B209, JIS H4000-2006 .etc |

Thickness | 0.2-200mm aluminium 5050 H38 |

Width | 1250mm 1000mm or as your requirements |

Length | 3000mm 5800mm or as your requirements |

MOQ | 5 Ton |

Package | Standard export package, by wooden box or as require |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What characteristics distinguish pure aluminum from its alloyed forms?

- <p>Pure aluminum is a soft, lightweight, and highly malleable metal with good electrical and thermal conductivity. It is often used for its corrosion resistance and is relatively inexpensive. Aluminum alloys, on the other hand, are made by combining aluminum with other elements like copper, magnesium, silicon, or zinc to enhance its properties. These alloys are stronger, more durable, and can be tailored for specific applications, such as in aerospace, automotive, or construction. They offer improved strength-to-weight ratios, better resistance to heat and wear, and can be anodized for enhanced surface properties. While pure aluminum is more ductile and easier to weld, aluminum alloys provide greater versatility in terms of mechanical properties and performance.</p>

- Q: Explain the relationship between aluminum and iron in terms of their properties and uses.

- <p>Aluminum and iron are both metals with distinct properties that determine their various applications. Aluminum is lighter, more resistant to corrosion, and has good thermal conductivity, making it suitable for applications such as beverage cans, aircraft construction, and electrical wiring. Iron, on the other hand, is heavier, stronger, and more magnetic, which makes it ideal for construction materials, steelmaking, and electromagnets. They can be combined to form alloys, such as steel, which is an iron alloy with carbon and sometimes other elements, enhancing its strength and durability.</p>

- Q: Explain the impact of using recycled aluminum on the environment.

- <p>Using recycled aluminum significantly reduces our environmental footprint. It requires only 5% of the energy needed to produce new aluminum from raw materials, thus conserving energy. Additionally, recycling aluminum reduces greenhouse gas emissions by up to 95% compared to aluminum production from bauxite ore. This lowers air pollution and helps combat climate change. Moreover, recycling aluminum conserves natural resources and reduces the need for mining, which has its own set of environmental impacts, including habitat destruction and water pollution. Overall, recycling aluminum is a sustainable practice that benefits the environment by reducing energy consumption, emissions, and resource extraction.</p>

- Q: Explain how the strength of aluminum is affected by temperature changes.

- <p>The strength of aluminum decreases with increasing temperature. As temperature rises, aluminum undergoes thermal expansion, which can lead to a reduction in its yield strength and tensile strength. This is because the increased thermal energy causes the aluminum atoms to vibrate more, weakening the metallic bonds. At very high temperatures, aluminum can become ductile and may even lose its structural integrity. Conversely, at very low temperatures, aluminum can become brittle, which also affects its strength negatively. Therefore, the optimal temperature for maintaining the strength of aluminum is typically within its normal operating range.</p>

- Q: Is there any health risk associated with using pure aluminum cookware?

- <p>Using pure aluminum cooking utensils is generally considered safe for most people. However, there are some concerns regarding the potential for aluminum to leach into food, especially at high temperatures or with acidic foods. While the health risks are still a subject of debate, it's recommended to use aluminum cookware with a protective coating or opt for utensils made from other materials like stainless steel or cast iron for long-term health considerations.</p>

- Q: This question asks about the impact of adding tin to aluminum alloys on their characteristics and longevity.

- <p>Adding tin to aluminum alloys can significantly alter their properties and durability. Tin enhances the alloy's strength, hardness, and resistance to wear, making it suitable for applications requiring high mechanical properties. It also improves the alloy's corrosion resistance, particularly in marine environments. However, the addition of tin can reduce the alloy's ductility and formability, which might limit its use in certain applications that require extensive shaping or bending. The overall durability of the alloy is improved due to the increased resistance to environmental factors, but it's essential to balance the alloy composition to optimize its properties for specific applications.</p>

- Q: Explain the distinctions between aluminum alloys and pure aluminum in a few sentences.

- <p>Aluminum alloys and pure aluminum differ in composition and properties. Pure aluminum is soft and has low strength, making it less suitable for structural applications. In contrast, aluminum alloys are made by combining aluminum with other elements like copper, magnesium, or silicon to enhance strength, durability, and resistance to corrosion. These alloys maintain the lightweight nature of aluminum while offering improved mechanical properties, making them ideal for various industries, including aerospace, automotive, and construction.</p>

- Q: Explain the process by which aluminum forms alloys.

- <p>Aluminum forms alloys by combining with other elements, such as copper, magnesium, silicon, manganese, and zinc, among others. This process involves melting aluminum and the alloying elements together in a furnace. The molten mixture is then cooled and solidified to form an alloy. The resulting alloy has properties that are different from pure aluminum, such as increased strength, corrosion resistance, and improved machinability. The specific properties of the alloy depend on the elements added and their proportions. Alloying allows for the customization of aluminum's characteristics to suit various applications in industries like aerospace, automotive, and construction.</p>

- Q: Is it possible to use pure aluminum for crafting jewelry or sculptures?

- <p>Yes, you can use pure aluminum for jewelry making or sculpture, but it's not as common as other metals due to its lower melting point and softer nature. Pure aluminum is lightweight, affordable, and easy to work with, making it suitable for certain types of designs. However, it's not as durable or resistant to scratches as metals like silver or gold, and it may require special care to maintain its appearance. It's also important to consider the potential for allergic reactions, as some people are sensitive to aluminum.</p>

- Q: This question asks for the specific temperature at which aluminum oxide transitions from a solid to a liquid state.

- <p>The melting point of aluminum oxide (Al2O3) is approximately 2072掳C (3767.6掳F). It is a high melting point due to the strong ionic bonds between aluminum and oxygen atoms in the crystal structure. This high melting point makes aluminum oxide a common material in high-temperature applications such as refractory materials and abrasives.</p>

Send your message to us

High Quality Aluminum Plate Alloy 5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords